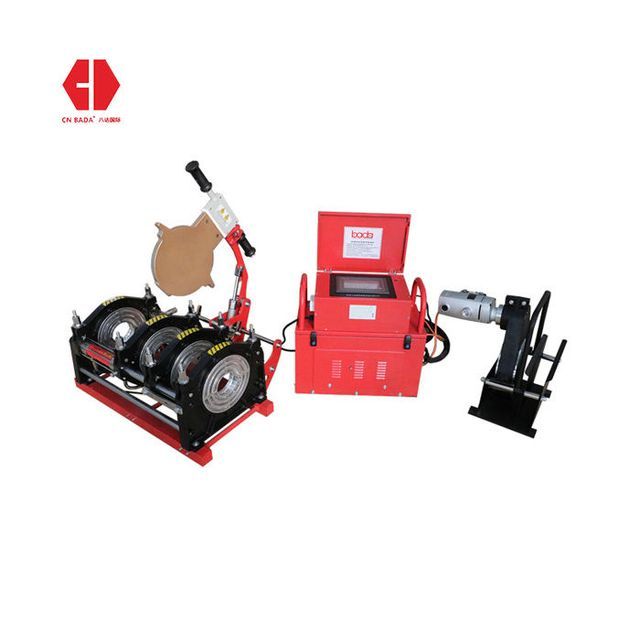

160-315mm automatic hydraulic butt welding machine PE HDPE pipe fittings butt welding machine connection equipment

-

Supplier: Jinan Bada Plastic Pipe Welding Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Ms Will Tan -

Price: $3750.00 /set -

Min. Order: 1 set

Product details

| Showroom location: | not any | Applicable industries: | Manufacturing plants, farms, energy and mining |

| Main selling points: | Low maintenance cost | OEM: | acceptable |

| Weldable materials: | Plastic pipe butt welding equipment | Single piece packaging size: | 86X57X44 cm |

| Total power: | 3500W | usage: | Butt welding machine |

| Welding method: | Butt welding equipment | Core components: | Engine, motor |

| Input voltage: | 220V 50Hz | Health status: | new |

| Material: | Aluminum & stainless steel | After-sales service provided: | High quality automatic HDPE pipe welding plastic welding machine |

| Marketing type: | 2020 new products | Place of origin: | Shandong Province, China |

| Mechanical test report: | if | Sales unit: | Single product |

| Welding materials: | PE PPR PP polyvinylidene fluoride | pack: | Standard export plywood packaging |

| Warranty: | 2 years | Certification: | EU CE certification |

| Package preview: | Gross weight of single piece: | 68.000kg | |

| Warranty: | 2 years | Video outbound inspection: | if |

| Power (kW): | 3500W | Weight (kg): | 180kg |

| brand: | bada | Core component warranty: | 2 years |

| aspect: | 86*57*44 | Packaging details: | The goods are packed in three-layer standard export plywood boxes covered with plastic film. |

90-250mm high quality automatic HDPE pipe butt welding machine

Butt welding machineWelding machine HDPE plastic automatic PE pipe automatic welding machine

Product Description

1. Welding records cannot be tampered with, and welding parameters cannot be modified manually. 2. This machine can store about 500 welding records. These welding records can be copied by connecting to a computer or by connecting a microprinter. 3. Backtracking function: welding position, pipe material, equipment manufacturer and other data. date. Operators and welding parameters can be traced in real time. 4. International standards include: ISO, UNI, DVS, WIS, TSG5, etc. The heating plate can bounce by swinging the arm.

Equipment Specifications | ABBD250V |

Welding range (mm) | 90-250mm |

voltage | 220V 50Hz |

Control box power supply | 900 watts |

Milling head motor power | 1360 watts |

Heating plate power | 2100W |

Total welding power | 4360W |

ambient temperature | -10~+40° |

Working pressure range | ≥10Mpa |

Pressure resolution | 0.01MPa |

Pressure accuracy | 0.1MPa |

Time resolution | 0.1S |

time accuracy | 0.1S |

Hot plate temperature control accuracy | ±3℃ |

Cylinder area | 11c㎡ |

Heating plate ejection time | 1.5-3.5 seconds |

1. High-power milling cutter, mirror cutterhead, powerful motor, high concentricity, and stable milling. 2. The milling motor uses a high-power Bosch drill bit, which is powerful and non-slip. 3. The milling cutter is equipped with a limit switch and can only be rotated when it is placed in the frame to prevent accidental injury.

powerful

Our advantage

1) Advanced laboratories

2) Mature fusion welding technology

3) Spare parts warehousing quality inspection, production process inspection, complete machine inspection and debugging before leaving the factory.

4) Cooperate with well-known universities, participate in the drafting of GB national standards, provide training for domestic and foreign fusion welding technicians, and support free online video guidance.

5) The spare parts inventory is sufficient, the delivery time is short, within 50 sets, the delivery time is 7-10 working days, and it complies with ROHS 2.0 standards.

2) Mature fusion welding technology

3) Spare parts warehousing quality inspection, production process inspection, complete machine inspection and debugging before leaving the factory.

4) Cooperate with well-known universities, participate in the drafting of GB national standards, provide training for domestic and foreign fusion welding technicians, and support free online video guidance.

5) The spare parts inventory is sufficient, the delivery time is short, within 50 sets, the delivery time is 7-10 working days, and it complies with ROHS 2.0 standards.

1. Shipping: 3 days after receiving payment 2. Packing: Standard export plywood box 3: Our machine will be wrapped with plastic film and finally put into wooden box. This type of packaging avoids rust easily.

VIEW MORE

You may like

-

315mm to 630mm plastic pipe HDPE butt welding machine PE PP hydraulic semi-automatic butt welding machine

-

Welding 315mm Hydraulic Welding Machine HDPE Pipe Butt Welding Machine 380V Manufacturer Price

-

OEM Factory Low Price Portable Arc 2 in 1 Inverter Welding Machine AC 380V 315A 230A Welding Equipment

-

Welping China Factory 250mm Hydraulic Pe Plastic Pipe Butt Welding Hdpe Pipe Welding Machine

-

pe extrusion tool pvc pipe cutting tool

-

HDPE pipe poly plastic Thermofusion PE 90-315mm hdpe butt welding heat welding machine

-

220V china made hdpe pipe welding electromechanical fusion machine

-

HDPE pipe fittings handmade butt welding machine for sale

-

90mm to 250mm HDPE manual butt welding machine pe pipe hot joint machine

-

Factory Wholesale Mini Butt Welder Band Saw Blade Welder Butt Welder With Tempered Band Saw Blade

Other Products

-

$500.00 - $570.00 / unit

$500.00 - $570.00 / unit -

$1300.00 - $1380.00 / unit

$1300.00 - $1380.00 / unit -

$1300.00 / unit

$1300.00 / unit -

$360.00 / set

$360.00 / set -

$250.00 / set

$250.00 / set

Related Search

hdpe pipe fitting butt fusion welding machine

hdpe pipe fitting electrofusion welding machine

hdpe pipe fitting butt fusion machine

hdpe pipe fittings electrofusion welding machine

hdpe pipe fitting butt weld suppliers

hdpe pipe fitting electrofusion welding

automatic cnc butt welding machine

hydraul butt fusion weld machin suppliers

hydraul butt fusion machin suppliers

automat hydraul machin tool suppliers