V-S30 Fully Automatic Scrap Copper Wire Granulator Recycling Machine Copper Recycling Machine

-

Supplier: Xi'an Vaner Machinery Co., Ltd. -

Region: Shaanxi, China -

Contact: Ms Arya Choi -

Price: $18999.00 /set -

Min. Order: 1 set

Product details

| Model: | V-S30 copper granulator | Warranty: | 1 year |

| Machine size: | 3500*1800*2400mm | Power (kW): | 47 |

| Weight (kg): | 3000 | Main selling points: | automatic |

| strength: | 47kW | Packaging details: | Packaging: 1) Inner packaging: The machine is covered with plastic film; 1*20GP 2) Outer packaging: Plywood box |

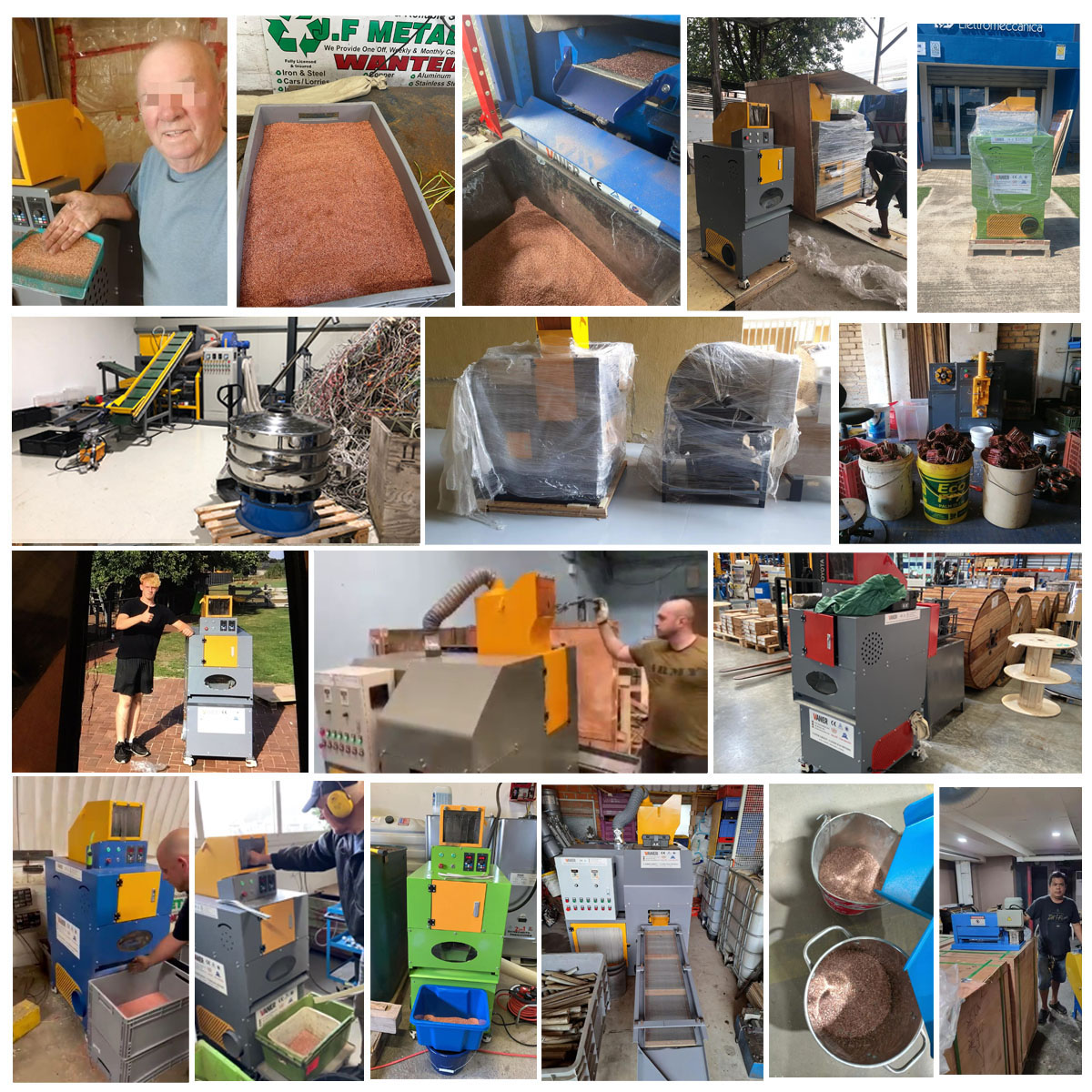

| Showroom location: | South Africa, Brazil, Saudi Arabia, Mexico | Marketing type: | New product |

| Materials/Metal Processing: | Brass/Copper, Aluminum | Mechanical test report: | if |

| Certification: | CE | Voltage: | 110V/220V/380V/customized 1 phase |

| Stripping range: | Below 30mm | Core component warranty: | 1 year |

| Separation rate: | 99.9% pure copper | Place of origin: | Zhejiang, China |

| Supply capacity: | 100 sets per month | Health status: | new |

| Name: | Copper recycling machine | Core components: | PLC, engine, motor, gear |

| Video outbound inspection: | if | weight: | 3000kg |

| Applicable industries: | Cable recycling machine, scrap metal recycling | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| capacity: | 400-500kg/hour | brand: | Varner |

| port: | Ningbo/Shanghai |

Product Description

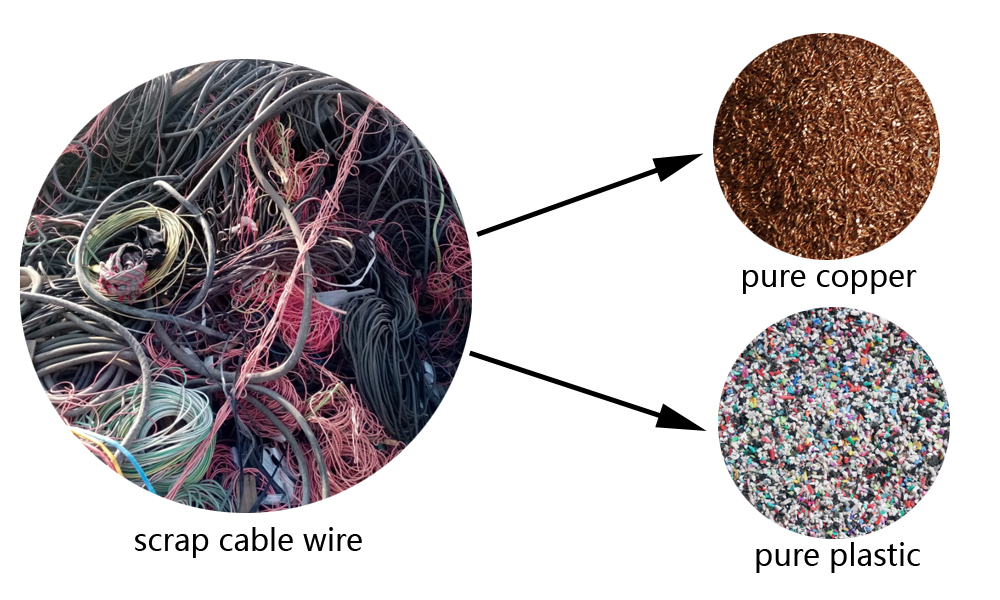

The VANER S30 copper wire pelletizer is designed for home and factory use and is also beneficial to scrap yards. If you are looking for a machine with a processing capacity of 400-500 kg/h,suitableWith its small footprint and easy operation, the S30 copper wire splitter is your best choice. The S30 copper wire granulator can process various cables below 30mm, such as household cables, square wires, wires, etc.

It has large output and low energy consumption. High sorting rate, one-time loading, and comprehensive cooperation between multiple machines. It is used for crushing waste copper wires and separating copper and plastic. The efficient system processes waste cables at about 400-500kg/h.

Best price for maximum profit. A great choice for small businesses and wholesale.

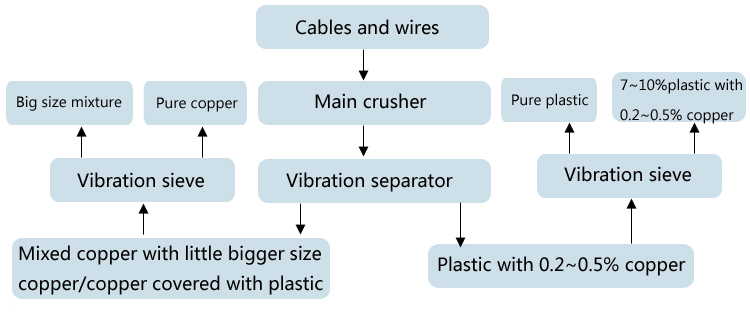

work process

Copper cable recycling equipment processing steps:1. The material is crushed by the crusher to obtain plastic skin and copper particles. 2. The crushed material (mixture of copper and plastic) is transported to the separator by the conveyor. During this process, the plastic particles (including fibers, ropes or belts mixed in the wires) are removed by the dust collector. 3. The air separator consists of a separation plate, a motor, etc., and is used to separate plastic and copper. 4. Each unit forms an overall structure for easy transportation. The machine has been adjusted and ready for production before shipment, and customers only need to plug in the power supply.

Standard spare parts

our service

Specification

Model | capacity | scope | strength | weight | mia |

V-C02 | 20-40kg/hour | 0.1-30mm | 4.2kW | 310kg | 5*45*140cm |

V-C03 | 50-80kg/hour | 0.1-30mm | 5.18kW | 515kg | 100cm*58cm*170cm |

V-C06 | 50-80kg/hour | 0.1-30mm | 13kW | 1200kg | 136*136*191.5cm |

V-C10 | 100-200kg/hour | 0.1-30mm | 24kW | 1200kg | 250*190*210cm |

V-S20 | 200-300kg/hour | 0.1-30mm | 26.8kW | 1600kg | 255*200*255cm |

V-S30 | 400-500kg/hour | 0.1-30mm | 49.1kW | 3200kg | 350*80*250cm |

V-S35 | 600-800kg/hour | 0.1-30mm | 75kW | 5 tons | 5*6.5*3m |

V-S50 | 800-1200kg/hour | 0.1-30mm | 69.3kW | 6 tons | 7.2*7.5*2.2m |

V-S55 | 1200-1800kg/hour | 0.1-30mm | 94.8kW | 8.5 tons | 12*4.3*3m |

Packaging and shipping

This small copper wire granulator is almost the cheapest copper wire recycling machine available on the market, but it has all the functions of crushing and sorting. The best choice for small scrap wire recycling stations and start-up recycling companies.

VIEW MORE

You may like

-

High performance small copper cable shredder mini cable shredder used copper wire shredder

-

High-quality PCB recycling equipment/PCB dismantling machine

-

BSGH Mini Cable Granulator Waste Cable Wire Separator Recycling Machine at 220 V with the most advanced technology and good quality

-

industrial iron ore crusher plant price

-

Shredder Double Shaft Shredder, Shredder, Waste Plastic Shredder

-

2022 Best Selling Cable Wire Granulator Grid Grinding Separator Recycling Machine

-

Factory direct sales metal pipe bender round pipe bender iron pipe bender

-

Double shaft scrap metal shredder used car shredding scrap metal shredder

-

Copper Wire Pelletizer Splitter/Small Copper Wire Pelletizer

-

American copper dismantling winding machine / motor rotor cleaning machine recycling machine best-selling scrap copper making machine

Other Products

-

$1100.00 / set

$1100.00 / set -

$7270.00 - $7470.00 / set

$7270.00 - $7470.00 / set -

$7200.00 / set

$7200.00 / set -

50-80 kg/h mini copper granulator scrap copper cable granulator per kg pure copper recycling machine$6970.00 - $6980.00 / set

50-80 kg/h mini copper granulator scrap copper cable granulator per kg pure copper recycling machine$6970.00 - $6980.00 / set -

$255.00 / set

$255.00 / set -

$999.00 / set

$999.00 / set -

$2820.00 - $6870.00 / set

$2820.00 - $6870.00 / set -

$220.00 - $433.00 / set

$220.00 - $433.00 / set -

$999.00 / set

$999.00 / set

Related Search

scrap copper wire stripping machine

copper wire granulator

wire stripper machine scrap copper

millberry scrap copper wire

scrap copper wire separator machine

fulli automat wire coil machin suppliers

coconut oil machine fully automatic

fulli automat nitrogen generat

fully-automatic blow moulding machine

induction machine smelting scrap copper