Commercial small factory ketchup making machine ketchup production line ketchup

-

Supplier: Henan Zhong Yi Long Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms ZHONG YI LONG MACHINE -

Price: $23999.00 / 1 - 1 sets

$22000.00 / >=2 sets -

Min. Order: 1 set

Product details

| Core components: | Motors, pressure vessels, pumps | strength: | customizable |

| Applicable industries: | Manufacturing plants, food and beverage plants, farms, home use, food stores, food and beverage stores | brand: | Zir |

| Weight (kg): | 5000 | Package preview: | |

| Warranty: | More than 5 years | Suitable: | Snack food processing factory |

| raw material: | Mustard Raspberry Date Jam Maker Tomato Sauce | Mechanical test report: | if |

| Supply capacity: | 20 sets per month | Processing type: | Industrial tomato processing line |

| Health status: | new | Place of origin: | Zhumadian |

| Video outbound inspection: | if | capacity: | 1T-20T |

| Showroom location: | Uganda | pack: | Aseptic filling, can filling, bottle filling, jar filling, etc. |

| Machine material: | Food grade stainless steel 304 | Finished goods: | Tomato sauce, ketchup, tomato sauce, tomato puree |

| Voltage: | customizable | Dimensions (length*width*height): | customizable |

| Core component warranty: | 5 years | Marketing type: | normal product |

| feature: | Mustard Raspberry Date Jam Maker Tomato Sauce | thing: | Tomato paste production line |

| model: | customizable | Heating source: | Steam+Electricity |

| application: | Food industry, mustard raspberry date jam machine ketchup | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Production capacity: | customizable | Packaging details: | Tomato paste production line is packed directly in the container. |

| port: | Qingdao, Shanghai, Tianjin, Guangzhou, etc., according to your requirements |

Factory price fully automatic ketchup ketchup production line ketchup making machine processing price jam making

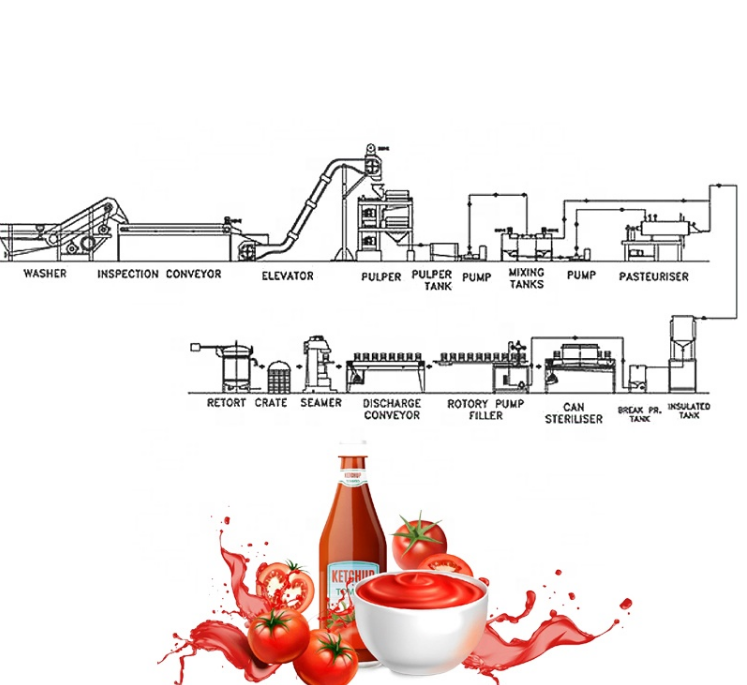

Complete Tomato Sauce Production Line Instructions

1. Tomatoes are usually processed into paste. The processing line mainly includes five parts: fresh tomato receiving, pre-washing and sorting section, crushing and beating section, concentration section, pasteurization or sterilization section, aseptic filling section, and auxiliary energy Work section.

1. Tomatoes are usually processed into paste. The processing line mainly includes five parts: fresh tomato receiving, pre-washing and sorting section, crushing and beating section, concentration section, pasteurization or sterilization section, aseptic filling section, and auxiliary energy Work section.

2. Production capacity includes 10 tons, 20 tons, 30 tons, 50 tons, and 100 tons of fresh tomatoes per day.

3. The concentration rate of tomato paste is 28%, 30%, 32%, 36%, and 38%.

4. Tomato paste can be filled into barrels or canned sterile bags, and can also be further processed into canned/bottled/bagged tomato paste, sauce, juice, etc.

3. The concentration rate of tomato paste is 28%, 30%, 32%, 36%, and 38%.

4. Tomato paste can be filled into barrels or canned sterile bags, and can also be further processed into canned/bottled/bagged tomato paste, sauce, juice, etc.

Product Description

Tomato puree/tomato sauce/tomato paste/tomato paste production line can help you make tomato puree, tomato puree, tomato sauce, and tomato sauce using fresh tomatoes as raw materials. The tomato paste production line includes tomato washing machine, tomato sorting machine, tomato crusher, tomato beater, tomato evaporator, tomato paste/ketchup mixing tank and sterilizer. The ketchup production line will be equipped with aseptic filling machine, bottle filling machine, can filling machine according to your final filling type.

Tomato sauce production process:

Fresh/ripe tomatoes - tomato cleaning - sorting - tomato crushing - tomato pulping - vacuum concentration - paste sterilization - filling.

Fresh/ripe tomatoes - tomato cleaning - sorting - tomato crushing - tomato pulping - vacuum concentration - paste sterilization - filling.

Tomato processing lines can produce different types of tomato products:

*ketchup*Ketchup*Ketchup*Tomato sauce*Tomato juice

As a turnkey tomato project supplier, just send us your requirements and we will provide you with a professional solution. Welcome to >>Inquiry.

Tomato processing production line can be customized according to your needs

needs and workshops,Please feel free to contact us.

Advantages of tomato paste production line

1The entire tomato sauce production workshop is made of SUS 304 stainless steel to ensure the hygiene and safety of the tomato sauce production process.

2. The drum sorting machine can be designed with spray devices, collection channels, and garbage conveyors.

3. The tubular preheater and tubular sterilizer can be designed with an insulation layer.

4. The fruit pulping machines in tomato processing plants have a variety of mesh sizes to choose from.

5. The concentrator is small in size, simple in structure, and easy to operate, clean and maintain.

6. The design concept of energy saving and emission reduction saves more than 20% energy than tomato paste processing plants in the same industry.

Introduction to ketchup making machine:

The entire ketchup production line can produce ketchup, ketchup, jam, etc.

Automated and efficient. Different capacities: 300kg/hour, 500kg/hour,1000kg/hour. ETC.

Tomato paste making machine process:

Clean → Preheat → Beat → Grind → Mix → Sterilize → Pack.

The entire ketchup production line can produce ketchup, ketchup, jam, etc.

Automated and efficient. Different capacities: 300kg/hour, 500kg/hour,1000kg/hour. ETC.

Tomato paste making machine process:

Clean → Preheat → Beat → Grind → Mix → Sterilize → Pack.

This line is a small tomato paste production line. The production process is carried out in strict accordance with the installation standard manufacturing process, and the final product meets the requirements of food hygiene conditions. Product filling and packaging forms can be configured according to the retail requirements of the mall.

Chapter 333

application

Tomato filling types, aseptic bag filling, glass bottle filling, automatic can filling, jar filling, PET bottle filling and bag filling, please choose the type you want, we will equip it for you Suitable filling machine.

Product Details

Tomato cleaning machine

Tomato bubble cleaning machine is also called tomato floating cleaning machine. Equipped with spray cleaning device. Pushed by the water in the conveyor trough, the tomatoes follow the water flow and enter the next process. Clever double-layer design allows sand and gravel to settle to the bottom layer and be discharged

Tomato beater

Tomato pulping machine is suitable for separating crushed and pre-cooked tomato pulp residue. The first channel is for coarse pulp, and the second channel is for fine pulp. The equipment has the advantages of reasonable structure, high efficiency, high pulp output rate, fast separation speed, large production capacity and good stability.

Tomato evaporator/concentrator

The tomato paste vacuum continuous evaporator is suitable for continuous evaporation of fluid materials such as tomato paste under vacuum and low temperature conditions to achieve the effect of concentrating into tomato paste.

Tomato ketchup/sauce mixing jar

Mixing tanks are used to mix tomato paste with other ingredients like salt, sugar, ginger and sterilize it into the final product.

Vat filling line.

This machine is suitable for liquid metering and filling, automatically completing feeding,

Positioning, weighing, filling, unloading, capping, coding, and conveying. Widely used in fertilizer, chemical industry, food and other fields

other industry.

Positioning, weighing, filling, unloading, capping, coding, and conveying. Widely used in fertilizer, chemical industry, food and other fields

other industry.

Small bottle filling line

The servo quantitative filling machine realizes metered filling of different viscous liquids. Widely used in wine, condiments,

Filling of daily necessities, beverages, jam and other viscous liquids.

Filling of daily necessities, beverages, jam and other viscous liquids.

capping machine

Easy to operate: The host machine has frequency conversion speed regulation, which can automatically realize bottle flipping and reversal, and is easy to operate.

Fast bottle management. Various types of workstations can be customized according to customer requirements to meet

Compatibility of various products.

Fast bottle management. Various types of workstations can be customized according to customer requirements to meet

Compatibility of various products.

Labeling machines

Optional matching labels, single and double labeling, optional positioning detection device, can realize

Locate the label. Can be equipped with ribbon printer and inkjet printer to print production date and batch number information

Labels, integrating labels and inkjet printing.

Locate the label. Can be equipped with ribbon printer and inkjet printer to print production date and batch number information

Labels, integrating labels and inkjet printing.

Carton packing machine

The cartoning machine is fully automatic from column setting, grabbing, moving, placing, output and other actions without any operation.

Manual; at the same time, this equipment can be adjusted according to different products and the grabbing system can be different

There are many types of cartons, and the adjustment time does not exceed 5 minutes. One machine has multiple uses and strong performance. It is an enterprise

Realize the automation of large-scale production of equipment.

Manual; at the same time, this equipment can be adjusted according to different products and the grabbing system can be different

There are many types of cartons, and the adjustment time does not exceed 5 minutes. One machine has multiple uses and strong performance. It is an enterprise

Realize the automation of large-scale production of equipment.

Palletizer

Palletizers are mainly divided into three types: robot palletizers, column palletizers and gantry palletizers.

Suitable for packaging and production enterprises of finished products in cartons, bags, cans, boxes, bottles and other shapes

Palletizing. This machine is suitable for packaging by manufacturers of chemicals, beverages, food, beer, plastics, air conditioners, etc.

And palletize the finished products into various shapes

Suitable for packaging and production enterprises of finished products in cartons, bags, cans, boxes, bottles and other shapes

Palletizing. This machine is suitable for packaging by manufacturers of chemicals, beverages, food, beer, plastics, air conditioners, etc.

And palletize the finished products into various shapes

product photo

VIEW MORE

You may like

-

Industrial Fine Herb Spice Chilli Berry Grinder Grinding Machinery Ginger Sugar Salt Powder Making Machine

-

Potato Chips Snack Seasoning Machine Star Anise Fried Peanut Seasoning Machine Roller Seasoning Machine

-

Spice Sauce Jacketed Steam Kettle 100 1000l / 20litter Steam Jacketed Kettle/Industrial Hot Jacketed Kettle

-

Electric energy, gas, electromagnetic heating new type of food industry processing seasoning fried stuffing wok

-

Fully automatic chili sauce with spicy sauce making machine and food cooking pot sugar cooking equipment

-

Stainless Steel Industrial Food Grinding Crusher Sugar Spice Grinder Ultrafine Powder Grinder

-

Low-consumption chili sauce sandwich wok

-

100 Gallon Steam Jacketed Kettle/Candy Jam Gas Tilt Jacketed Kettle Cooking Pan/Stir Jacketed Kettle

-

Electric Jacketed Cooker with Stirrer / Tilting Soup Cooking Jacketed Cooker / Electric Oil Steam Jacketed Cooker

-

Octagonal Mixer Stirring Seasoning Machine Seasoning Processing Machine

Other Products

-

$7000.00 - $7900.00 / set

$7000.00 - $7900.00 / set

Related Search

commercial gelato ice cream making machine

small milk powder making machine

commercial pringles potato chips making machine

steel frames making machine furring channel line

machin juic product line suppliers

small commercial bread making machines

small cheese making machine

small biscuit making machine

commercial empanada making machine

bamboo toothpick machine|toothpick machine production|toothpick making machine