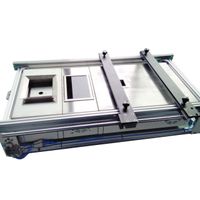

High quality 3 zone wave soldering machine SMT machine factory price

-

Supplier: Shenzhen JAGUAR Automation Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Ruby Li -

Price: $1888.00 /set -

Min. Order: 1 set

| Marketing type: | normal product | Gas source: | 0.5MPa |

| Weight (kg): | 1300kg | weight: | 1300kg |

| aspect: | 3300(length)*1420(width)*1750(height) | Video outbound inspection: | if |

| Mechanical test report: | if | current: | 60A |

| Preheating method: | heat | Supply capacity: | 30 sets per month |

| External dimensions: | 3900*1420*1750mm | Packaging details: | wooden box |

| usage: | SMT production line | Main selling points: | Precise temperature control |

| Rated working cycle: | 24 hours a day | Core component warranty: | 1 year |

| Warranty: | 1 year | Rated Capacity: | Options |

| Preheating consumption: | 220V 8kW | port: | Shenzhen |

| Applicable industries: | Building materials stores, machinery repair shops, manufacturing plants, retail, construction engineering, machinery, electronic production, electronic controllers, consumer electronics, home appliances, EMS, LED lighting, LED controllers | type: | soldering machine |

| Preheater channel: | 1600mm | Package preview: | |

| Place of origin: | Guangdong, China | payment terms: | L/C, Western Union, D/P, D/A, T/T |

| Voltage: | 220V 8kW | Solder pot capacity: | 320kg |

| Core components: | PLC, engine, motor, pump | brand: | Jaguar |

| Number of preheaters: | 3 | Showroom location: | Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Kenya, South Korea, South Africa, Japan, Malaysia, Australia |

| Health status: | new |

JAGUAR 3 Preheat zone lead-free hot air wave soldering N35

Specification:

|

model. |

Jaguar N350 |

|

Number of preheaters |

3 |

|

Preheater channel |

1600mm |

|

body size |

3300(length)*1420(width)*1750(height) |

|

Dimensions |

3900(length)*1420(width)*1750(height) |

|

weight |

1300kg |

|

Total/stable consumption |

24KW/6-8KW |

|

Gas source |

0.5MPa |

|

Preheating method |

heat |

|

Preheater consumption |

220V 8kW |

|

control method |

Computer+PLC |

|

Temperature range set point |

Room temperature---300℃ |

|

Preheat time |

Set to 150℃ for about 10-15 minutes |

|

welding applications |

Lead-free/ |

|

Tin pot capacity |

320kg |

|

Solder pot temperature |

300℃ |

|

Solder pot consumption |

380V 12KW |

|

Welding temperature control method |

PID&SSR |

|

Wave motor consumption |

250Wx2 220V |

|

Solder melts |

Set to 250℃ for about 120 minutes |

|

Printed circuit board width |

50-350mm |

|

Conveyor speed |

300-2000mm/min |

|

Conveyor direction |

L→R (R→L optional) |

|

solder angel |

4-7° |

|

flux pressure |

3-5 bar |

|

flux capacity |

6.5 liters |

Iintroduce:

1. Energy-saving, lead-free application, in line with environmental protection requirements, humanized design

2. Automatic power supply system, inverter control, automatic board loading function.

3. The flux spraying machine adopts a horizontal Japanese nozzle, driven by a stepper motor, with a selectable spray range and PLC control, which is accurate and reliable.

4. The flux recovery container has a drawer-type design for easy cleaning.

5. The conveyor is equipped with 3 width-adjustable screws, which makes the conveyor transmission more stable and eliminates the risk of PCB falling.

6. Titanium welding finger, high-strength double V-shaped groove, tin-resistant

7. PID closed-loop control hot air preheater, the preheating system adopts three-level independent temperature control to ensure good thermal insulation effect, uniform temperature and temperature accuracy of ±2℃.

8. The modular design of the preheating channel is environmentally friendly, safe and easy to clean.

9. The soldering motor adopts imported high-frequency variable frequency motor, which is independently controlled and has stable performance.

8. The impeller of the soldering pot is made of cast iron and will never corrode. The soldering pot is equipped with an oxidation sheath and has low tin slag.

11. The soldering furnace has a timed start function, and the solder melts within 90 minutes.

12. Equipped with automatic finger cleaner.

13. With black box storage function, the machine can store SPC data at any time to improve work efficiency.

14. Intelligent monitoring and alarm system ensures stable performance and operator safety.

-

USB 3.0 3.1 Type C Connector Cable Hot Rod Double Sided Welding Machine

-

Professional portable MMA welding machine Fronius Transpocket Italian distributor

-

Mini selective wave welding machine with nitrogen protection

-

Foot-operated automatic soldering machine robot tin welding gun tin welding machine soldering machine 936 constant temperature

-

USB Automatic Soldering Machine Charging Cable Making Machine

-

Desktop hot pressing rod automatic soldering station selective automatic soldering robot/soldering equipment

-

USB Cable Automatic USB Welding Machine Welding Machine

-

USB Cable Maker Wire LED Light Welding Machine

-

automatic usb cable welding machine usb cable making machine for usb cable