CNC steel stirrup bending machine/reasonable structure fully automatic bending machine

-

Supplier: Xingtai Penghao Machinery Manufacturing Co., Ltd. -

Region: Hebei, China -

Contact: Ms Melody Wang -

Price: $12000.00 / 1 - 2 sets

$11800.00 / >=3 sets -

Min. Order: 1 set

| Certification: | Chief Executive | Number of shapes: | 100 types |

| Single packing size: | 20X14.5X0.5cm | Health status: | New |

| Core component warranty: | 1 year | Dimensions (L*W*H): | 3280*1000*1700mm |

| color: | Yellow (customized) | Core components: | engine |

| Angular accuracy: | ±1° | Applicable industries: | Manufacturing plants, retail, construction |

| Sales Unit: | Single item | Video factory inspection: | if |

| automation: | Automatic | Weight (kg): | 1350 |

| Mechanical test report: | if | Origin: | Hebei, China |

| Brand Name: | Penghao | Processing materials/metals: | Carbon Steel |

| Key selling points: | Automatic | Double line: | 4-8 mm |

| Warranty: | 1 year | Name: | Automatic bending machine |

| Exhibition Hall Location: | No | Single line: | 4-12 mm |

| Maximum traction speed: | 60m/min | Maximum bending speed: | 800°/sec |

| Marketing Type: | Ordinary products | Gross weight per piece: | 0.300 kg |

Automatic wire cutting, stripping and bending tools

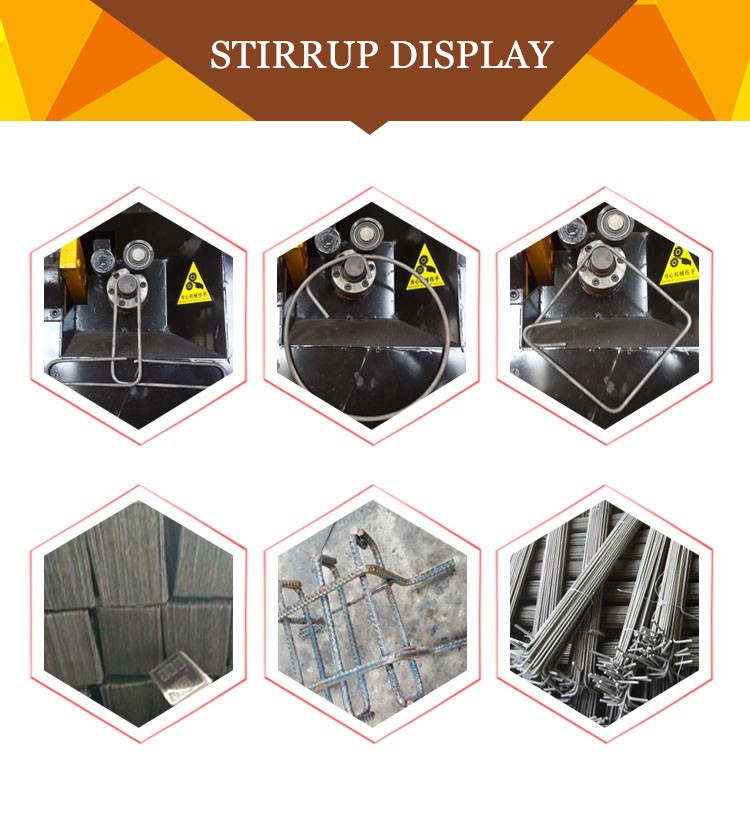

Introduction of Automatic Stirrup Bending Machine

1. Automatic stirrup bending machine is used for bending stirrups.

2. The automatic stirrup bending machine adopts high-quality, fast and energy-saving steel structure construction technology to ensure high efficiency and effectiveness.

3. It also provides the premise for low price and high quality.

4. Diverse varieties, capable of producing more than 100 different types of workpieces

Advantages of automatic stirrup bending machine

1 This equipment adopts servo control system;

2 Automatically complete the functions of feeding, straightening, bending, cutting, etc. of steel bars;

3. The maximum bending diameter of steel bars is 12mm;

4 Continuous bending of various stirrupsof a two-dimensional figure;

5. With bidirectional bending function, the steel stirrup bending machine can produce special shapes;

6. High efficiency and accurate processing precision.

7. Double roller synchronous wire feeding system, easy to use and easier to learn

parameter Automatic stirrup bending machine

Features of automatic stirrup bending machine:

The fully automatic hoop bending machine adopts intelligent control and can process various sizes such as square, rectangle, polygon, diamond, etc. It also has straightening and cutting functions. It can be used for multiple purposes, which greatly improves production efficiency and reduces labor costs.

It adopts microcomputer control, has powerful functions, good expansibility, Chinese subtitles, interactive operation, and is simple and easy to learn.

The speed is set in stages, the bending accuracy is high, and multi-angle workpieces can be completed at one time.

In addition, it can be equipped with auxiliary tube pushing, core tube existence and other functions, and can also bend thin-walled tubes.

Applicable materials: round steel, threaded steel bars, stainless steel, copper tubes, aluminum tubes; connecting accessories: special molds, anti-wrinkle plates, auxiliary devices, etc.

-

Automatic CNC steel bar bending stirrup bending machine price

-

Factory price steel bar bending machine high quality steel bar bending machine for sale

-

GF20 CE Standard Fully Automatic Steel Stirrup Bending Machine

-

Fast Stirrup Bending Machine Small CNC Stirrup Bending Machine

-

Cheap Steel Bar Stirrup Manual Stirrup Bending Machine

-

Manual Wrought Iron Wire Reinforcement Bending Hoop Tool

-

GW40B 6-40mm Steel Bar Stirrup Bending Machine

-

New Manual Rebar Bending Machine Rebar Bending Tool Deformation Rod Folding Machine Construction Equipment

-

GF20 Steel Stirrup Ring Making Machine

-

CE approved electric rebar bender and cutter

Other Products

-

$99.12 / set

$99.12 / set