High standard agricultural grain seed cleaning machine wheat corn wind screen fine cleaning machine 5TPH

-

Supplier: Kaifeng Hyde Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Paige Zhao -

Price: -

Min. Order: 1 piece

High standard agricultural grain seed cleaning machine wheat corn wind screen fine cleaning machine 5TPH

Haide Machinery (Maosheng Group)

- Seed processing plant: 1~15 t/h

- Flour mill:40~1000 tons/day

- Manufacturer since 1976

5X Air Screen Cleaner Delicate cleaning

1) Function: Fine cleaning to remove impurities, broken grains and spoiled grains; classify seeds according to size.

2) Application: Grains and seeds.

3) Production capacity: up to 12t/h (wheat).

The 5X Air Screen Seed Cleaner has been developed for flexible, high-quality grain and seed cleaning. Can be used for pre-cleaning and deep cleaning, but mainly for seed cleaning.

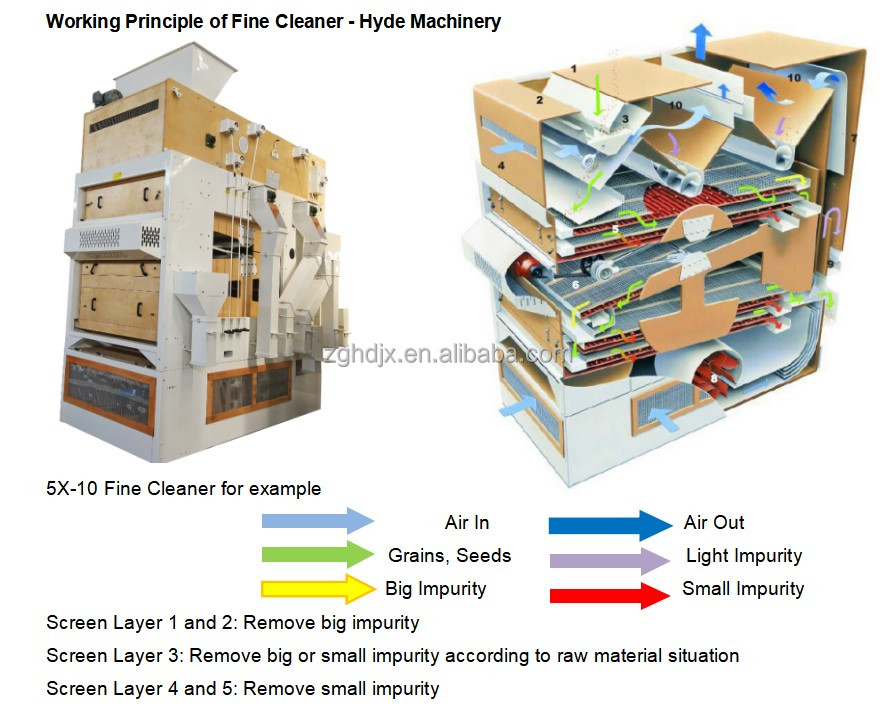

Working principle5X Air Screen Cleaner

Seeds and grains can be separated from impurities based on different physical and mechanical properties.

Separation is accomplished by:

1. Fan (blower): different according to weight and aerodynamic characteristics.

2. Screen mesh: Depending on the width and thickness of the seeds.

Excellent cleaning and grading capabilities are achieved through variable screen configurations, front and rear suction systems, and air lift fans at the bottom. Enclosed, bolted and painted steel construction ensures long service life and safe operation.

application5X Ultra-Fine Seed Cleaner for Dry Bean Cleaning

5X air screen cleaning machine is widely used for cleaning grains and seeds, such as wheat, barley, lentils, rice, corn, spices, grass seeds and forestry seeds.

Multi-layer cleaning screens can be easily replaced to meet different processing requirements.

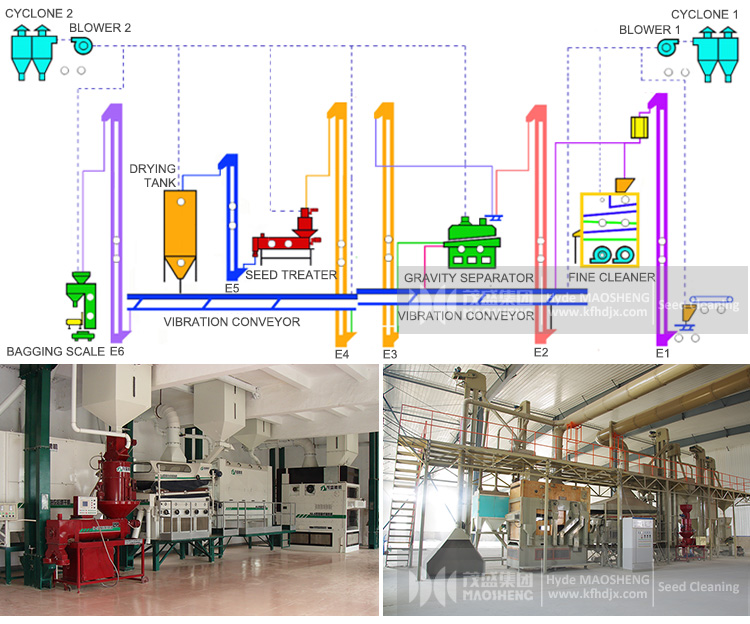

5X air screen fine cleaning machine in seed cleaning plant(Corn, wheat, rice, etc.)

advantage5X air filter cleaner for cleaning coffee beans

1) The multi-layer screen is installed in reverse, and the product is discharged from the bottom layer, which has a good cleaning effect on large and small impurities.

2) The upper and lower screen ships are installed in opposite directions, with good dynamic balance and smooth operation.

3) The screen is easy to replace and can be flexibly adapted to different processing requirements.

4) There are positive and negative pressure blower systems on the top, outside and bottom to remove light impurities and diseases twice.

5) The screen frame, light debris settling chamber, and feeder components are all made of high-quality wood, with good sealing and vibration-absorbing properties, and low operating noise.

6) The adjustable range is wide and easy to adjust, making it easy to realize the fine cleaning process.

7) The integrated steel frame rubber ball tray is used for screen cleaning, making it easy to clean the screen and machine.

8) Each moving part is equipped with safety protection devices to ensure safe operation.

9) Box-type screen structure effectively reduces dust content in the workshop.

10) The machine structure is symmetrical, and the discharging system can be left or right-mounted according to the customer's site conditions.

Contact us

Technical specifications5X Air Screen Cleaner

|

Model |

5X-5 |

5X-12 |

|

Overall dimensions (length × width × height) |

3200×1920×3600mm |

3790×1940×4060mm |

|

gross weight |

3250kg |

3600kg |

|

Rated capacity (wheat) |

5 tons/hour |

10~12 tons/hour |

|

total air inflow |

8200 cubic meters |

12520 cubic meters |

|

strength |

||

|

Top blower (optional) |

4-72N0-5A, 7.5 kW |

4-79N0-6A, 11kw |

|

Screen vibration motor |

2.2kW |

Y132S-8, 2.2 kW |

|

Bottom lifting system motor (VVVF motor) |

3.0kW |

3.0kW |

|

Feeding motor (VVVF motor) |

1.5kW |

WR41-Y0.75-4P-1.68-M1, 1.5kW |

|

total power |

6.7kW |

6.7kW |

|

Screen |

||

|

Screen type |

perforated screen |

|

|

Screen size (length × width) |

800×1250mm |

|

|

frequency |

300(80~400)/minute |

|

|

amplitude |

30mm |

|

|

Number of layers and quantity |

4 layers, 7 pieces |

5 layers, 15 pieces |

|

first floor |

1 piece, round hole |

3 pieces, slotted |

|

second floor |

2 pieces, slotted |

3 pieces, slotted |

|

third floor |

2 pieces, slotted |

3 pieces, slotted |

|

fourth floor |

2 pieces, slotted |

3 pieces, slotted |

|

fifth floor |

/ |

3 pieces, slotted |

notes:

1. A single machine is equipped with 1 set of screens (7 pieces or 15 pieces) and no top fan.

2. The machine can switch to different cleaning procedures, and the screen should be replaced accordingly.

3. The above technical data may vary due to ongoing development or different machine configurations.

5X Quinoa Sorghum Rice Millet Fine Dried Bean Washing Machine

Grain and seed cleaning machines:

Pre-cleaning machine, fine cleaning machine, rotary cleaning machine, seed grader, seed gravity separator, toothed drum, wheat field awn remover, stone removal machine, vibration cleaning machine, rotary cleaning machine, suction Air blower, cyclone dust collector, seed treatment machine, seed dryer, elevator and conveyor, automatic packaging scale.

Air sieve fine cleaner seed gravity separator toothed drum separator

Stone Separator Vibrating Screen Cleaner Separator Rotary Cleaner

Kaifeng Haide Machinery is a branch of Henan Maosheng Group. Its predecessor was Kaifeng No. 2 Grain and Oil Machinery. It is an enterprise specializing in grain and oil machinery engineering and equipment manufacturing.Grain handling, storage, flour milling and seed processing since 1976.

After 40 years of growth, Maosheng Group has become one of the world's leading companiesTop ten grain processing machinery manufacturers in China.In addition, Maosheng is also the hostChina National Grain Processing Technology Research Center.subsidiariesCOFCO2019.

Kaifeng Haide Machinery was separated into a branch company in 2000, mainly producing a full range of advanced machinery and equipment.Grain and seed processing machinery.

Seed processing machinefrom Haide Machinery

cooperateMaosheng Group Haide Machinery

In order to better serve customers, Maosheng Group not only imports high-end manufacturing equipment to improve product quality and production efficiency, but also constantly seeks international exchanges and cooperation. In 2009, we successfully signed a machine development agreement with Italy and established a joint venture with Italy. Westrup, Denmark 2013 andNorogard Sweden2016.

Our partners and customers in China:

Honors and QualificationsMaosheng Group Haide Machinery

After decades of our efforts, our machines have gainedChina's top ten, China's famous trademarksAnd enjoys a high reputation in domestic and foreign markets.

Member of the drafting unit of 13 national standards for China's grain industry. 75 patents, including 4 inventions (as of 2017).

Why choose us?

-

40 years of manufacturing experience since 1976.

-

Top ten grain processing machinery manufacturing enterprises in China.

-

Member of the drafting unit of 13 national standards for China's grain processing industry.

-

75 patented technologies and products.

-

The production area is 600,000 square meters.

-

More than 100 experienced engineers, researchers and technicians.

-

State of the art facilities. Advanced imported functional parts CNC machine tools.

-

Comprehensive service for the grain and flour industry from stand-alone machines to turnkey systems.

-

The quality of mechanical equipment has been tested by domestic and foreign markets, and we have rich experience in installation and troubleshooting.

National leaders visitMaosheng Group affirms our efforts in the grain processing industry

Pre-sales service

1. Technical consulting services

Our broad product range allows us to offer our customers the most flexible, efficient and reliable equipment configurations or complete solutions according to different requirements and budgets.

2. Company and production line visit

Customers are warmly welcome to visit Hyde and our factory before placing orders. We can also arrange visits to existing customers to check on the operating status of our machines and complete equipment.

Sales service

1. Reliable delivery time.

2. Strict quality control, 100% inspection and testing during production.

3. User manual and spare parts are provided free of charge.

After-sales service

1. Rapid technical guidance on construction, installation and debugging.

2. Necessary on-site daily maintenance training.

3. 12 months warranty.

4. Life-long regular technical services.

5. Solve problems promptly.

Q: What do you need to know for quick communication and quotation?

A: We would be grateful if you could provide detailed processing material specifications, capacity and efficiency requirements, screen specifications, motor power supply voltage and special brands required, and other working conditions.

Q: What is the delivery time of dry bean cleaning machine?

A: 15~30 working days, depending on machine type and parts availability.

Q: What are your payment terms?

Answer: T/T, L/C, Western Union, cash accepted.

30% deposit is paid together with the purchase order, and 70% balance is paid before shipment.

Q: How do you ensure quality?

A: Quality control through incoming material inspection, 100% in-production inspection and post-packaging random inspection.

Provide timely spare parts and technical solutions for machine failures.

Q: How can we visit your company?

Answer: Haide Machinery is located in Kaifeng City, Henan Province, China.

It is an hour's drive from the nearest Zhengzhou Airport.

Welcome to inquire about seed cleaning machine, wheat corn air sieving fine cleaning machine!

Check the information below or simply fill out the form and click "Send".

-

200TPH Lackeby RotoSieve Trommel Screen

-

Cheap Grain Cleaning and Sifting Machine Grain Sifting Machine Grain Cleaning and Grading Machine

-

New rotary vibration cleaning machine corn pre-cleaning cleaning machine rice processing machine

-

Small Grain Cleaner Wheat Rice Destoner Cleaner/Grain Cleaner

-

Agricultural Machinery Grain Cleaning Machine Corn Wheat Sunflower Seed Cleaning Equipment

-

6FW-G12 Corn Corn Wheat Beans Grain Cleaning Machine

-

Wheat Corn Pepper Rice Grinder Five Grain Flour Mill Spice Grinding Mill

-

Different Models of Wheat Stone Remover Washers and Dryers

-

Multifunctional Rice Corn Wheat Soybean Sorting and Grading Machine Grain Sorting Machine Screening Machine

-

Factory Price Seed Washing Machine Rice Cocoa Bean Air Separator

Other Products

-

$200000.00 - $220000.00 / set

$200000.00 - $220000.00 / set -

$26000.00 / set

$26000.00 / set