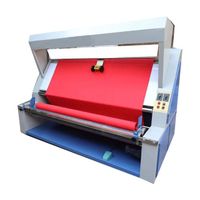

Latest sublimation printing Rotary heat press calender machine for polyester fabric

-

Supplier: Hangzhou Aeon Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Zhengfeng Xu -

Price: $29000.00 /unit -

Min. Order: 1 unit

| Supply Ability: | 50 Unit/Units per Month Heat press calender machine; | Voltage: | 380V; |

| Warranty: | 1 Year; | Certification: | Ce Certificates; |

| Weight: | 4500kg; | Power(W): | 65KW; |

| Brand Name: | Aeon; | Working temperature: | 220-240 centigrade degree; |

| Mechanical speed: | 1-20 meters / minute; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Place of Origin: | Jiangsu China (Mainland); | Dimension(L*W*H): | 1850*3380*2000; |

| Port: | Shanghai; | Heating parts power rate: | 60KW; |

| Condition: | New; | Recommended working area: | 4770*3200; |

| Printing width: | 1800mm; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Heat press calender machine; |

| Heating drum diameter: | 800mm; | Automatic Grade: | Automatic; |

| Motor parts power rate: | 5KW; | Machine size / weight: | 1850*3380*2000 / 4500KGS; |

| Power supply: | 3 phase, 380V, 50HZ; | Machine type: | Sublimation transfer machine; |

| Packaging Detail: | The Heat press calender machine is packed in wooden case.; |

Latest sublimation printing Rotary heat press calender machine for polyester fabric

1. The heating tubes in the heating drum easily got break and oil leakings occured because the different expansion rate from heating tubes to heating drum body. It is head ache problem for end users.

2. After one or two years production, the conduct oil got oxidized. It changes into sticky mud like things, poor flowing ability, so temperature difference on different parts of heating drum happened easily while it is the key element to keep the same color shade on transfer printing process.

3. OK. So you need to change all oxidized oil by fresh oil. First of all, the oxidized oil can not be removed throughtly from the heating drum since they are sticking on the wall inside of the heating drum closely. Secondly, how do you deal with those mud like oxidized oil when they are harmful to enviroment.

The Latest sublimation printing Rotary heat press calender machine for polyester fabric is designed to meet the increasing demand for high quality ink jet Dye-sublimation heat transfer technology. It is the perfect machine for industrial scaled producer who require high production speed and printing quality. But very economical price.

Main features:

1. Vacuum oil drum be heated by centralized resistor. Energy consumption saving and efficient, it just need 40 minutes to reach 200℃ working temperature. Temperature different will be controlled ±1℃.

2. Compact machine structure design for easy and safety operation. Very reasonable designed emergency stop structure to maximum protect the worker safety.

3. Automatic alignment device equipped

4. Electromagnetic system is used so even very thin paper can run on this machine properly.

5. All mechanical activities are completed by independent motor, therefore the problems brought b the electrical circuit or unfixed pulley system can be avoided.

6. Independent electrical cabinet design extended the machine life-span tremendously.

7. The safety system for the sudden power failure is provided.

8. The blanket can be separated from the heating drum manually according to user habit.

9. Machine switch on/off preset function is equipped.

10. For continuous production consideration, the second heat transfer paper roll loading is also equipped on this machine. In this way, fabric material is also maximum saved.

Technical parameters:

| HM500-2000/2600/3300 | HM800-2000/2600/3300 | HM1000-2000/2600/3300 |

Oil drum width | 2000/2600/3300mm | 2000/2600/3300mm | 2000/2600/3300mm |

Oil drum dia. | 500mm | 800mm | 1000mm |

Working width | 1800/2400/2800mm | 1800/2400/2800mm | 1800/2400/2800mm |

Speed | 1-15m/min | 1-20m/min | 1-25m/min |

Machine size | 1850 X 3380/3860/4560 X 2000mm | ||

Net weight | 3.8MT | 4.5MT | 5MT |

Power rate | 48-65KW | 65-100KW | 80-120KW |

Machine schematic:

-

Artos Peek material slide (1 large + 2 small) + 4 brass rivet stenter dyeing, coating finishing machine

-

Ingredients Spare Parts Production Line Used Chain Price Sizing Brush Finishing Stenter Textile

-

High-efficiency production of new automatic textile finishing machine fabric double-roller machine

-

CE certification European market welcomes T-shirt automatic folding machine

-

Industrial fabric shrinkers, steam and thermosetting machines

-

Needle bar for vertical Bruckner stenter dyeing and finishing machine

-

Automatic Textile Winding Machine Cloth Winding Machine Roll-to-Roll/Fabric Winding Folding Cutting Machine/Fabric Rewinder

-

Fully automatic fabric winding fabric inspection machine roll to roll fabric cutting printing machine

-

New version of foldimate clothing folding machine automatic clothing folding machine

-

High Quality T Shirt Automatic Folder Machine Clothes Commercial Laundry Folder T Shirt Folding And Packing Machine