QT4-15 paving block making machine/hydraulic concrete block machine/hollow block making machine

-

Supplier: Shandong Shiyue Intelligent Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms Anna Wang -

Price: $10000.00 /set -

Min. Order: 1 set

| Function: | make blocks ,bricks,paving,curbstone; | Weight: | 5T; |

| Single package size: | 710X160X261 cm; | color: | according to your needs; |

| Capacity: | 6144-9600pcs/8 hours; | Method: | Hydraulic Pressure; |

| Package Type: | Nude packages According to your needs QT4-15 paving block making machine/hydraulic block machine/hollow block making machine; | Raw material: | concrete,cement,sand ,flyash and so on; |

| Place of Origin: | Shandong China; | Applicable Industries: | Construction works ; |

| Certification: | ISO9001/CE/SGS; | After-sales Service Provided: | Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; |

| Product Name: | QT4-15 paving block making machine/hydraulic block machine; | Key Selling Points: | High quality block machine; |

| Processing: | Brick Molding Machine; | hydraulic: | yes; |

| Brick Raw Material: | Concrete; | Selling Units: | Single item; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Condition: | New; |

| Automatic: | Yes; | Type: | Hollow Block Making Machine; |

| Brand Name: | shiyue; | Dimension(L*W*H): | 7100*1600*2610mm; |

| Warranty: | 1 Year; | Single gross weight: | 4,500 KG; |

| Molding cycle: | 15s; | Voltage: | according customers' need; |

| Vibration frequency: | 2800-4500 ( R/min); |

| You may still interested in our following machine |

QT4-15 paving block making machine/hydraulic block machine/hollow block making machine

| Introduction |

1. The machine adopts hydraulic system and the working procedure is very even and dependable, hydraulic

press together with efficiently vibration make the shape, it which has high density and good quality.

2. It is a practical machine that simple in structure, artistic in figure. Especially suitable to the production of the

standard bricks, it can produce various kinds of paving bricks, porous bricks, roads bricks etc.

3. The reasonable material proportion have the capacity of making highdensity standard bricks, what’s more,

it can be piled up directly.

| Specifications |

1With spare parts

2 .Need pallets

3. Higher capacity

4. One year guarantee

5. Concrete interlocking bricks making machine

| Main Parameters |

Overall Dimension | 7100*1600*2610mm |

dimension of host machine | 2800*1800*2550mm |

Rated Pressur | 16MPa |

Main Vibration Form | Platform Vibration |

Vibration Frequency | 4600 ( r/min) |

Pallet Size | 1020*570*20/25mm |

Molding cycle | 15-25 (s) |

Overall Power | 27.5KW |

Host machine power | 19.2kw |

Vibration Force | 40KN |

General water consumption | 4T/day |

Total Mass | 5T |

Demolding method | Hydraulic |

Mixer model | JQ500/JD500/JS500 |

Molding area consumption | 400*800mm |

Factory Area | 500m2 |

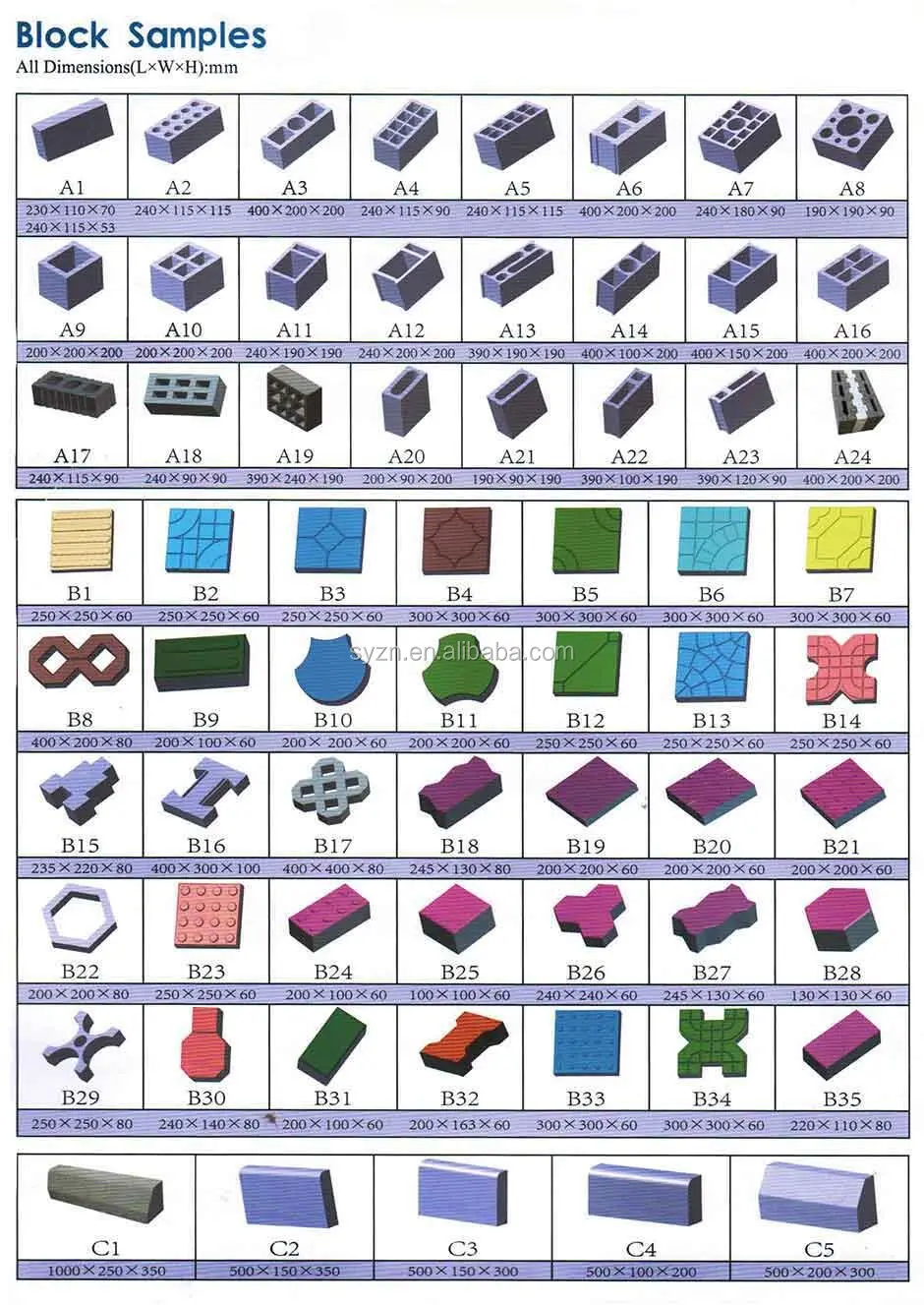

Applied Products | Concrete blocks, hollow/solid blocks, pavers, interlocking blocks , curbstone, colored pavers ,etc. |

Raw Material | Crushed stone, sand , cement, dust, and fly ash, gravel, slag, and other raw material , etc. |

Applied Fields | widely used in buildings, road pavers, squares, gardens, landscaping, city constructions, etc. |

certificate | ISO9001/CE/SGS |

Warranty | 1YEAR |

Processing | Brick Production Line |

Automatic | YES |

After-sales Service Provided | Engineers available to service machinery overseas |

| Machine photos |

| Capacity |

the machine can make many kinds of blocks only by changing the molds easily

Item | Specification size (mm) | Quantity per mold | Cycle molding | Per hour |

Hollow brick | 390*190*190 | 4pcs/mold | 15~20s | 720~960pcs/h |

Porous brick | 240*115*90 | 14pcs/mold | 15~20s | 2520~3360pcs/h |

Standard brick | 240*115*53 | 28pcs/mold | 15~17s | 5930~6720pcs/h |

| Delivery |

1. The whole brick machine production line equipment is mainly the full container sea shipping,

2. Brick machine equipments finish manufacturing and testing, next to clean up, and then do another paint protection,

3. Before shipment to use plastic film winding, wrapped the entire brick machine in case of water or moisture,

4. Then load brick machines into the container by forklift,

5. During loading to tighten the machine with reinforcement ring in container, so as to avoid the damage by transport bumps on the brick machine.

| Customer worksites: |

| Our company |

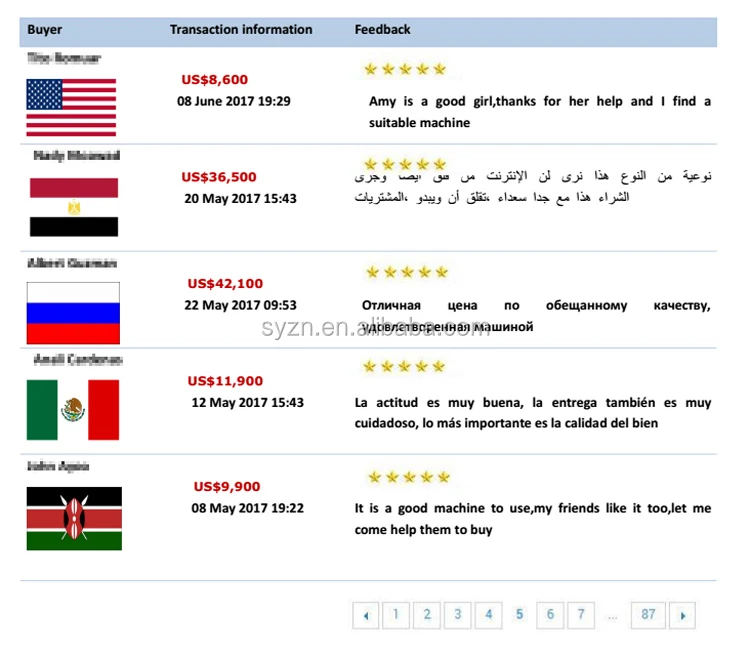

Shiyue Machinery is a professional manufacturer which is engaged in independently researching and developing, manufacturing and selling crushing equipment,block machine etc construction building machines. We have exported product to many countries, such as Mongolia, Russia, Philippines,India, Vietnam, Uzbekistan, Kyrgyzstan, Kazakhstan, Nigeria, South Africa,Oman ,Botswana, America etc. What’s more,we receive good feedback about service and quality. We are not main for sales, but also for development of the market all over the world. Do our best to satisfy customers’ need and gurantee quality is our principal .With 27 years’ brick block machine manufacture & export experience,welcome all the customers to our company and build business relationship with us.

| Customer visit |

These are our customers from all over the world, they are from Kenya, Tanzania, India, Russia, Australia, the United States, Ghana and other countries, Their arrival is a recognition of the quality of our brick machine and the affirmation of our service. We look forward to your visit.

| Our Team: |

We have professional service team, they are good at the knowledge of brick making machine, have rich experience, can answer all doubt for you in time. We hope our sincere service can bring you good purchasing experience. Looking forward to your long-term cooperation with your company. Thank you.

| Our services |

1) Send the technicians to carry out the installation and debugging of equipment for the foreign users with compensation. Countries or regions with unstable political situation or in the throes of wartime are not included in our plan.

2) Train the users to command the equipment and guide them for safe production.

3) Explain the routine maintenance of equipment carefully and remove common faults.

4) We are responsible for all the repairs that caused by our quality problems within one year’s warranty. (We will provide one set of spare parts/wear & tear parts free of charge with shipment.)

5) For some countries whose visas are difficult obtained, customers can also send their technicians to our company to receive free guidance and training.

6) Accept suggestions for improvement put forward by customers an earnest way. In accordance with changes of the market, provide the products and services to meet the user’s needs and create value for them.

7) We will make every effort to solve your problems, and your success will add new glory to us.

| FAQ: |

1> Is this block machine suitable for us to use?

Answer:Could you please tell us what kind of bricks do you want to make? And the capacity you want? Let us check if it can meet your request.

2>Which industry did this block machine usually be used in?

Answer: Interlocking bricks, Hollow bricks, Paving bricks,Solid bricks,etc

3>How to use the block machine?

Answer: We will send the operating manual to you after you purchase the machine, for bigger machine, we can offer engineer fly to your side for installation and training your workers.

4>How about the after sale service of block machine?

Answer: 1 year guarantee for the whole machine (without the spare parts).

5>what's your payment term

our common payment is 30% deposit by T/T before arrange the machine production,70% balance before the delivery,if other payment term,we can negotiation.

| Contact us |

-

Easy to operate sand plastic automatic making machine manual hollow block concrete brick mold

-

Machine for processing concrete bricks qT6-15 for sale, factory price

-

Songmao fully automatic brick making machine line electric cement hollow block machine

-

Precast Concrete Lightweight Wall Panel System for sale in Malaysia

-

The cement hollow brick mold brick making machine is easy to operate

-

Small Business Creative Scale Semi-Automatic Block Machine Concrete Interlocking Brick Machinery

-

High Quality Plastic Brick Tray GMT Tray For Brick Making Machine

-

Mobile small manual cement block interlocking concrete block and brick making machine in Tanzania

-

Thailand soil cement brick lego clay block making machine

-

Business philosophy of small investment small cement clay brick making machine

Other Products

-

$3800.00 - $3900.00 / set

$3800.00 - $3900.00 / set -

$7500.00 / set

$7500.00 / set -

$3500.00 / set

$3500.00 / set -

$16900.00 / set

$16900.00 / set