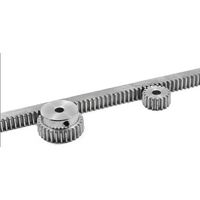

custom CNC machinery axle gears manufacturing

-

Supplier: Hangzhou Mory Trade Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr xing li -

Price: $5.00 / >=5 pieces -

Min. Order: 5 pieces

| Brand Name: | MORY; | Customer: | UK; |

| Applicable Industries: | Manufacturing Plant,Machinery Repair Shops,Construction works ; | Name: | custom CNC machinery axle gears manufacturing; |

| Packing: | bubble paper, carton; | Standard or Nonstandard: | Nonstandard; |

| Grade: | 45#; | Tolerance: | +/-0.02; |

| Packaging Detail: | plywood box; | Supply Ability: | 1000 Piece/Pieces per Month; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram,Paypal; | Material: | alloy steel; |

| Main process: | CNC lathe turning, gear hodding; | Processing: | Hobbing; |

| Finish: | NA; | Direction: | Left Hand; |

| Standard: | ENG; | Place of Origin: | Zhejiang China; |

| Pressure Angle: | 45; | Tooth Profile: | Herringbone Gear; |

| Material: | Steel; | Shape: | Cylindrical Gear; |

| Port: | Ningbo; | Application: | machine transmission system; |

custom CNC machinery axle gears manufacturing

Product Type | CNC gears |

Size | Customized |

Material: | Carbon Steel, Brass, Aluminium alloy, Stainless steel,steel alloy, POM, Delrin etc. |

Process Method | CNC machining, Turning, milling ,drilling, grinding,Wire EDM etc. |

Main Equipment | 1.CNC vertical machining center, 2.CNC horizontal boring machine. 3.High speed CNC lathes machine 4. CNC milling machine. 5.General milling machines.g 6.General manual lathes, 7. Flarness Gridning machines, 8. Manual drilling machine, 9.Wire EDM cutting machine |

Surface Treatment | Chrome plating Anodizing Powder coating Black oxide Sand blasting Brushing & ploshing Electrophoresis |

Tolerance | +/-0.01mm |

OEM/ODM Service | Available |

Sample Delivery | 5-7days |

Design Software | PRO/E, Auto CAD, Solid Works and Unigraphics NX |

Trade Terms | FOB,CIF,EXW |

Payment Terms | T/T, L/C, Western Union |

QC System | Provide Inspection Report |

Packing | Carton, Standard plywood boxes |

Delivery | 35 working days upon PO confirmed |

Shipment Terms | 1) 0-100kg: (DHL/TNT/UPS/FEDEX) / Air freight |

2) >100kg: sea freight or as customized specification | |

Applications Field | Automotive Parts,Hareware Parts,hydraulics, compressors,Construction,Machinery, Mechanical Engineer,Industrial equipments, transmission parts, etc. |

| Q | 1. Why choose us? |

| A | 1) Professional CNC machine shop for your all kinds of customized needs. |

2) One stop shop meet your requirements of CNC machining, milling,turning, drilling, boring,gridning,welding and fabricating. | |

3) Quality parts has been exported to US, UK, FR and RU. | |

4). We are direct factory focus on providing custom machining service. | |

5). Handling components of very tight tolerance and very complex geometry | |

6). MOQ small is even acceptable in some special conditions. | |

7). Top quality guaranteed by skilled and experienced workers, managing system and status of facilities. | |

8). Near Shanghai port and NIngbo port, convenient transportation | |

| Q | 2. How to guarantee the quality? |

| A | 1)We make samples for your testing quality prior to batch production. |

2)QC staff will inspect the parts before shipping. | |

3) We are responsible for our quality products. | |

| Q | 3. ODM service |

| A | Let us know your idea and what you want. Our mechanical engineering can design the print. |

Solidworks, autoCAD, UG are available for all kind of needs. | |

| Q | 4.OEM service |

| A | Our professional CNC machine shop provide CNC machining, turning,milling, drilling, grinding, boring, welding and fabricating service. We can meet your requirements. |

| Q | 5. How to contact us? |

| A | 1)You can leave us message on alibaba. |

2)visit our webpage to get the contact information |

-

Custom Sprocket Sprocket, Sprocket Sprocket Assembly

-

High precision spur gear pinion

-

Cheap High Precision Small Gear Micro Spur Gear Small Diameter Custom Cnc Machining Stainless Steel Sprocket Gear

-

Steel forging cylindrical involute tooth gear 0.25 modulus gear

-

Factory supply high quality tractor drive shaft planetary gear

-

Custom CNC milled brass machined gears

-

Factory custom high precision custom metal spur gear manufacturer steel spur gear steel gear

-

Hardened straight rack tooth surface heat treatment 1/1.5/2/2.5/3/4/5 mold rack

-

helical metal spur gear

-

Wholesale high quality spline sleeve manufacturers offer

Other Products

-

$75.00 - $150.00 / piece

$75.00 - $150.00 / piece -

$85.00 - $185.00 / piece

$85.00 - $185.00 / piece