High Quality carbonated soft drink beverages machine from Datong

-

Supplier: Zhangjiagang Datong Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Lynn Fan -

Price: $8000.00 /set -

Min. Order: 1 set

| Supply Ability: | 30 Set/Sets per Week carbonated Drink mixer; | Usage: | Mix Carbonated Drinks; |

| Product name: | High Quality carbonated soft drink beverages machine; | Place of Origin: | Jiangsu China; |

| Power(W): | 2.2~5.5kw; | Application: | Beverage, Food; |

| Packaging Detail: | We use standard wooden case for High Quality carbonated soft drink beverages machine from Datong .; | PLC: | SIEMENSE; |

| Warranty: | 2 Years; | Capacity: | 1000Liter/hour-10000Liter/h; |

| Processing: | Mixer; | Name: | carbonated Drink mixer; |

| Control syste: | Touch Screen; | Voltage: | 220V/380V; |

| Energy consumption: | low; | Material: | Stainless Steel; |

| Condition: | New; | Dimension(L*W*H): | 2*2*2.3; |

| After-sales Service Provided: | Field maintenance and repair service; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,carbonated Drink mixer; |

| Function: | mix water, flavors and CO2; | Port: | shanghai; |

| Certification: | CE ISO SGS; | Brand Name: | DATONG; |

| Processing Types: | Carbonated Beverage; | Weight: | 650kgs~7000kgs; |

Application of PET bottle carbonated drink filling machine:

Cola, carbonated water, soda water, etc.

Quality assurance:

1.This kind of complete set of drink filling machine combines washing,filling and rotary capping functions in one unit,is a fully automatic and high efficiency liquid packing equipment.

2.It is suitable for packing carbonated soft drink ,beverage containing gas. Its performance is as following all parts,for instance, filling valve, which directly contact medium are made of stainless steel or harmless material. So it conforms to the requirements of Food sanitation. Sealing parts are made of heat-proofing rubber from JST company, in order to meet the technique requirements of users to sterilization at high temperature.

3.filling machine ,using programmable controller to realize fully automatic control from bottles entering to finishing packing, Using transducer as speed regulator from JST company, so the user can regulate the machine easily to suit different power requirements, Adopting equal pressure filling principle and current spring valves in order to assure beverage quality, Using advanced magnetic coupler to regulate cap-screwing torque, in order to assure capping quality.

Technical of plastic bottle carbonated drink filling machine:

Feature of carbonated drink filling machine.

Full filling avoids the bottle distorted after cooling and reduces dissolved oxygen at the maximum degree.product storage hopper and feed system adopts reasonable product feed design(constant flow,constant pressure,no foaming).product hopper with reasonable structure(exhaust,fully close,temperature can be detected).medium and high speed line adopts product distributor instead of large liquid carousel,which can be cleaned completely by pressure cleaning with CIP.sanitary filling valve system umbrella-flow type structure,high speed.perfect hot filling temperature control system.product recycle tank system with automatic product feed startup.perfect CIP system.

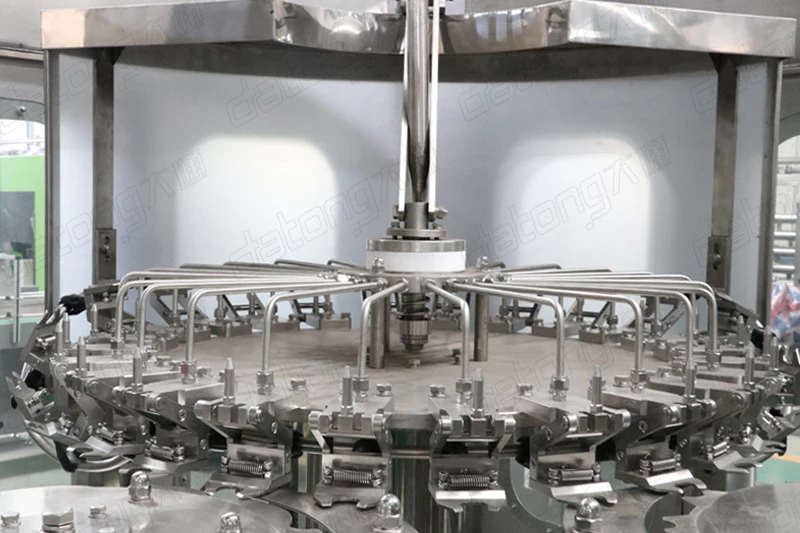

3-in-1 internal structure

The 3-in-1 unit completed the three processes of washing bottle, filling and sealing.

Washing part

Specially designed stainless steel bottle gripper does not contact the thread parts of the bottle neck,avoiding the second contamination.

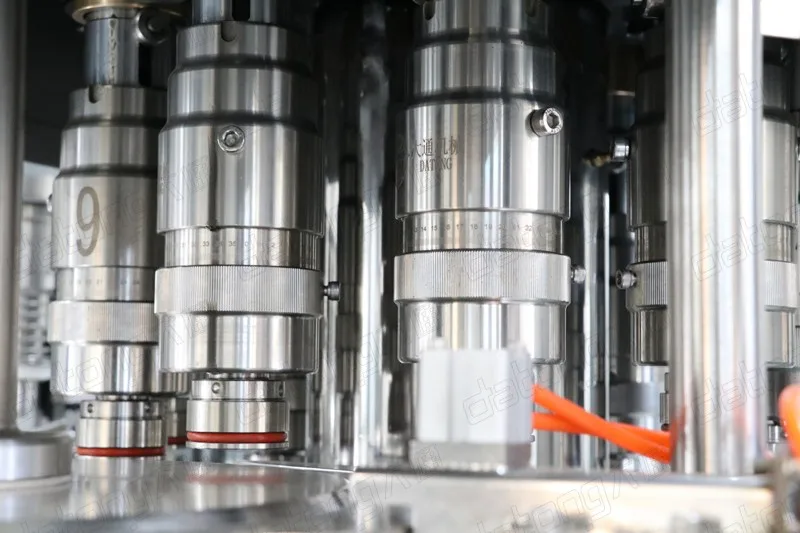

Filling part

High speed and mass flow filling valve ensures the high filling speed and exact fluid level.

Capping part

Capping head have itself scale.Easier adjust and count.

RO Water Treatment System

Process: Spring-raw water booster pump, mechanical filter, precision filter, active carbon filter, sodium exchanger, RO machine/ hollow fiber ultrafiltration device, Store tank, UV sterilizer, ozone generator and other equipment.

Bottle blow molding machine

Automatic PET Bottle Blowing Machine is suitable for blowing PET bottles of various shapes, volume from 100 ml to 2000 ml, wide application for blowing mineral water bottles, soda bottles,cola bottles.

Sleeve labeling machine

This machine adopts exclusive-design multi-cutter, mining agencies combination of steel, smooth moves. The tools life is doubled. Simple center- guided positioning, more easily replaced specifications, make it easy for the operator to use.

Film shrinkable packing machine

Specially designed and manufactured for the high-speed packing requirements of drinks ( pure water, beverage, fruit juice, and milk product)

During the product forward conveying process, it can automatically group the product into package so as to save time and enhance packing efficiency.

Zhangjiagang Datong Machinery Co.,Ltd was founded in 2002. Actually has been specialized in Water & beverage packaging solutions over 16 years. Modern factory of 6000 square meters, all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, constitute DATONG excellence in manufacturing system.Over 40 countries use our machines.

China Zhangjiagang Datong machinery Co.,ltd.focused on water & beverage filling machine since 2002. We have rich experience and mature manufacturing.We have CE and ISO and TUV certificate etc. to prove our strength.

Why Choose DATONG?

1.Experience

DATONG Since 2002. We are professional in water&beverage solutions over 16 years.Modern factory of 6000 square meters.over 40 countries' customers are using DATONG machines.

2.Quality control

DATONG machines all parts adopts CNC (computer numerical control machine tools) for processing.Precision was improved greatly.

3. Reasonable Price

DATONG machines are highest cost performance. Our machines and good service worth your cost.

4. Warranty

DATONG provide 24 months long warranty, free parts and effective service in a timely manner. After the warranty, lifelong provide widely favorable technical support and after-sales service.

5. Turn-Key Project

DATONG's Turn-key Project including pre-sale and after-sale service, can provide the whole production line, factory design, design bottle, provide a layout diagram, provide auxiliary materials supply agent information, machine installation and debugging, staff training and so on.

6. After-sale service

DATONG will send engineers to customers factory. Offer installation, debug and technology training to customers.After sales hotline: 0086-512-58662088

DATONG can provide whole solutions for you!

Bottle Design Service.

Our engineer can design different bottle drawing for your reference!

Contact Us: We will send design drawing!

Layout Design Service.

We supply standard layout for each water filling machine line,

also available for customize design layout based on Customers Factory Area!

Give US: Factory Area.

Label Design Service.

Design colorful label for customers choice.

Provide Us: Information want to put on label.

DATONG Sales Service.

Before Sales

1.Answer your any question on us within 24 hours.

2.Supply all information you required.

3.Machines video for reference.

4.Welcome to visit factory.

On Sales

1.Update production progress each week.

2.Sending machines pictures on production .

3.Machines testing running over 8 hours, and sending testing videos.

After Sales

1.engineer arranged to install machines.

2.Spare Parts provided.

3.After sales hotline: 0086-512-58662088.

1.Q:Are you a factory or trading company?

A:We are a factory, professional water treatment equipment manufacturer and small bottle water production line with about 16 years experience. Factory covers an area of 6000 square. There have been more than 40 countries use our products.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Zhaxi economic development zone,Leyu town,zhangjiagang city,jiangsu province,china. about 2 hours away from podong Airport .we will pick you up in the nearest station. All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How long is the warranty of your equipment?

A:2 years warranty after receipt check upon delivery.And we will comprehensively provide you all kinds of technical support services in after-sale !

4.Q:What is the features of our company?

A: We provide turnkey project for customers, including pre-sale and after-sale service; complete production line equipment supply; bottle design; layout programs provide; or provide auxiliary materials purchasing agent supplier information; equipment overseas installation and commissioning; operator training; etc

We use wooden packing to protect machines are not damaged during the transit.

you can visit our company web www.datong-machine.com for more information. let us crate value for you.

-

Double Coat Cosmetic Cream Shampoo Homogenizing Emulsifying Liquid Soap for Tank Mixing with Agitator

-

Feed Mixer Powder Ribbon Mixer Powder Mixer 200kg

-

Baking Equipment 20 Liter Dough Mixer Planetary Spiral Mixer Dough Mixer

-

Steam heating double jacket stirring tank

-

500L stainless steel industrial chemical shampoo soap cone pressurized double jacket heating stirring mixing tank

-

Easy to Operate Automatic Beverage Mixer CO2 Carbonated Beverage Beverage Mixer Beverage Mixing Tank

-

Hot and cold juice mixing machine

-

Carbonated Beverage Soda Mixing/Sparkling/Carbonating Machine/Mixer/Carbonator

-

Commercial Sparkling Water Machine/Commercial Sparkling Water Machine/Industrial Carbonated Water Machine

-

1000L/H to 6000L/H Gas Juice Carbonated Beverage Single Tank Carbon Dioxide Co2 Blender

Other Products

-

$13000.00 / set

$13000.00 / set