Copper Electrolysis System Copper Refinery Plant

-

Supplier: Henan Recycle Environmental Protection Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr Andrew Zhang -

Price: $80000.00 /set -

Min. Order: 1 set

| Packaging Detail: | Standards Packing, Wooden case or As Customer Requirement for our Copper Electrolysis System Copper Refinery Plant; | Product Name: | Copper Electrolysis System Copper Refinery Plant; |

| Final product: | 99.99% Copper Cathode; | Applicable Industries: | Manufacturing Plant,Copper Electrolysis System; |

| Application: | Cathode Copper Making Plant; | After-sales Service: | Engineer Available; |

| Raw Material: | Contains 98.5% copper; | Port: | Qingdao Port Or Other China Port; |

| Weight (KG): | 10000; | Copper purity: | 99.99%; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | Usage: | Copper Electrolysis Copper Refinery Plant; |

| Keyword: | Copper Electrolysis System; | Key Selling Points: | 99.99% Copper Cathode; |

| Place of Origin: | Henan China; | Brand Name: | RECYCLE; |

| Warranty: | 2 Years; | Condition: | New; |

| Power (kW): | 280; | Supply Ability: | 5 Set/Sets per Month Copper Electrolysis System Copper Refinery Plant; |

| Electrolytic Cycle: | 15 Days; | Capacity: | 280-5000KW; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram; |

Copper Electrolysis System Copper Refinery Plant

Copper is a good conductor of electricity, and is used extensively to make electrical wiring and components. The purification of copper is a form of recycling. Copper is purified further using electrolysis and we call it Copper Electrorefining (electrolytic refining).

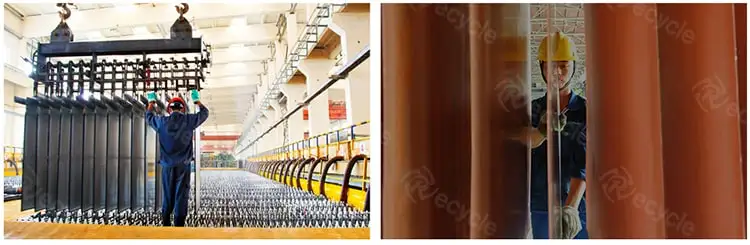

In industry this is carried out on a massive scale. The electrolytic copper production is processed in the huge copper electrolytic tank fulfilled with copper electrolytic solution. Even the best chemical method cannot remove all the impurities from the copper, but with electrolytic refining it is possible to produce 99.99% pure copper (whatever method is used to manufacture copper from its ore, its final purification is by electrolysis).

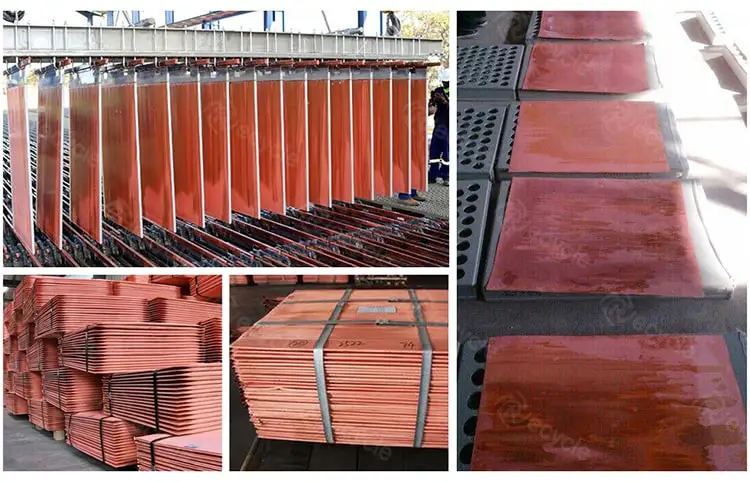

Customer work site of copper electrolysis project: Figure 1 shows the cathode plate and figure 2 shows the cathode copper after electrolysis. It is extracted from copper mine in smelting furnace, contains 98.5% copper. It is the raw material of electrolytic copper production. While the final electrolytic copper product contains 99.99% copper in it.

Copper electrolysis ,First,makes the crude copper which contains 98%-99.9% copper pouring into anode plate ,and use the pure copper sheet as cathode,then put them into the electrolytic cell (which has the copper sulfate and sulfate solution);

COPPER ELECTROLYSIS REFINING PLANT

Under the effect of direct current,the anode copper and poorer negative metal will be dissolved into the electrolyte,but the Gold, silver, palladium and other precious metals can't be dissolved, and they will be made into anode mud;

The copper which in the solution will be separated out preferentially, poorer metal that can't be separated out will stay in the solution ,they will be removed when purifying the electrolyte, that cathode will separate out more purer copper(99.99%), it will be called cathode copper or electrolysis copper.

The Specific Equipment Configuration Depends On The Output.

1. High current density, shorter anode distance, after processing the tail liquid can be consistent with national environmental requirements;

2. Advanced technology make the electrolytic cycle much shorter, automatic controlling, compared with other processes, labor costs can be reduced by 50%;

3. The exhaust gas treatment system can produce useful chemicals, creating added value.

-

2023 Vaner Small Wire Shredding Cable Copper Granulator Cable Wire Recycling Machine

-

50-80kg/hour mini copper granulator waste copper wire recycling machine

-

Mini Copper Granulator Copper Wire Shredder Cable Recycling Machine Scrap Metal Recycling Equipment

-

Aluminum Plastic Separator ACP Panel Plate Heating Separator

-

Copper cathode manufacturing equipment Copper electrolysis equipment

-

Dujiang Waste Plastic Products Recycling Plastic Bucket Crusher Double Shaft Shredder

-

Household cheap scrap copper wire granulator wire copper recycling machine 50KG/H waste cable copper recycling machine

-

50-80 kg/h mini copper granulator scrap copper cable granulator per kg pure copper recycling machine

-

2022 BSGH high-efficiency cable wire granulator and high separation rate copper recycling equipment BS-F1000

-

High quality control cable voltage power cable copper wire stripping machine

Other Products

-

$50000.00 / set

$50000.00 / set -

$1000.00 / set

$1000.00 / set -

$30000.00 / set

$30000.00 / set -

$19000.00 / set

$19000.00 / set -

$30000.00 / set

$30000.00 / set -

$80000.00 / set

$80000.00 / set -

$80000.00 / set

$80000.00 / set -

$50000.00 / set

$50000.00 / set -

$17500.00 / set

$17500.00 / set -

$5000.00 / set

$5000.00 / set