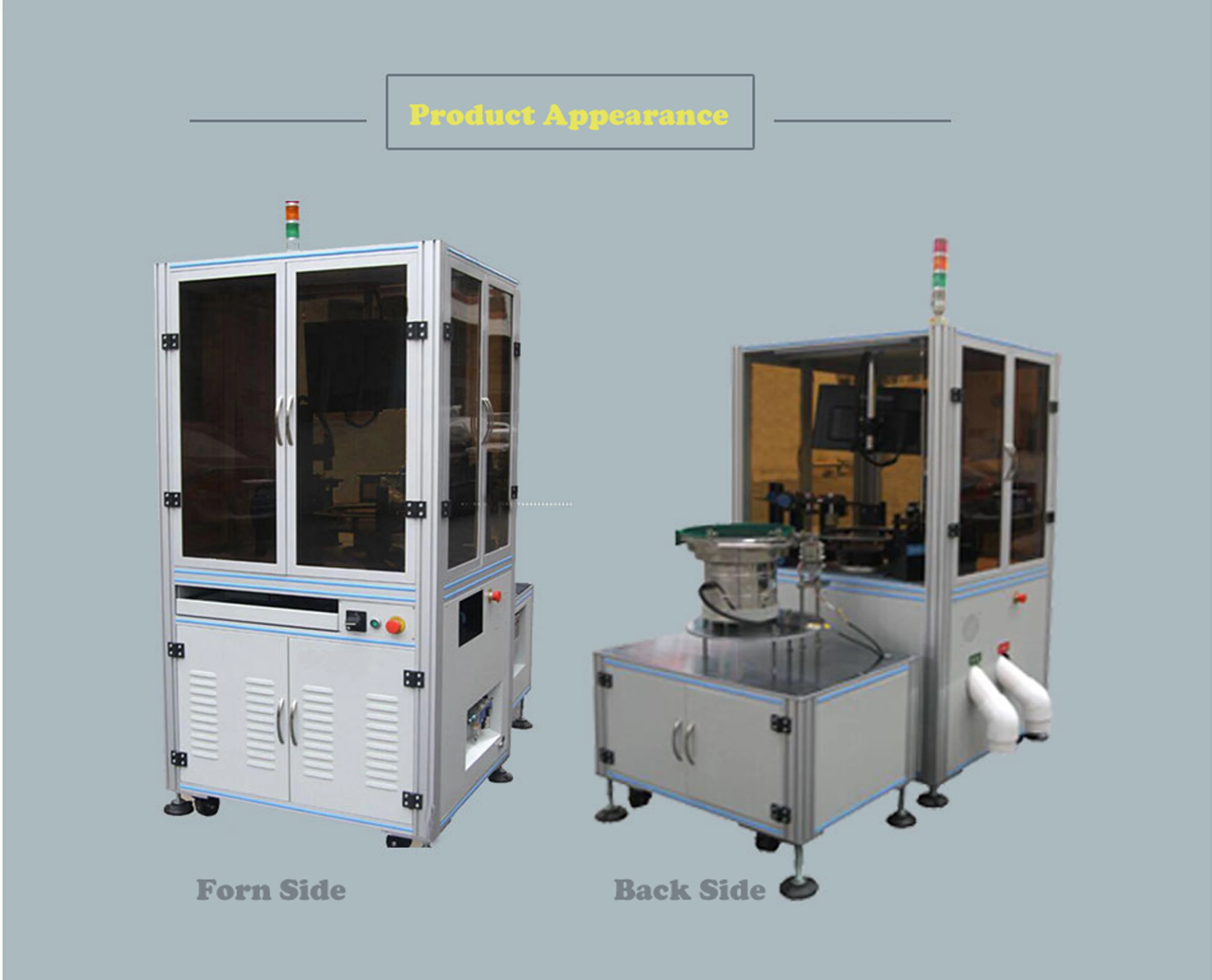

Sipotek Electronic Components Automated Visual Inspection Machinery for Surface Appearance Detection

-

Supplier: Shenzhen Sipotek Info Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Kathy Mai -

Price: $30000.00 /set -

Min. Order: 1 set

| Color: | White+Grey; | Applicable Industries: | Electronics Manufacturing Industry; |

| Function 2: | Fully automatic unqualified rejection; | Dimension(L*W*H): | 90*80*185 CM; |

| Product name: | Electronic Parts Inspection Machine; | Material: | Aluminum Alloy; |

| Voltage: | 220 V; | Certification: | CE; |

| Condition: | New; | Payment Terms: | L/C,T/T,Western Union,MoneyGram; |

| Feature: | Fully automatic and high accuracy to 0.01mm; | Power(W): | 1 KW; |

| Suitable for: | Electronic production company; | After-sales Service Provided: | Overseas service center available; |

| Function: | Automatically sorting unqualified items from mass production; | Port: | Shenzhen; |

| Supply Ability: | 30 Set/Sets per Month Electronics inspection sorting machine; | Warranty: | 1 YEAR; |

| Application: | Electronic Components Quality Guarantee; | Brand Name: | Sipotek; |

| Packaging Detail: | 1 x Quality vision inspection equipment Packed in protective wooden cases as per customer's requirements; | Place of Origin: | China; |

| Type: | High Automatic; | Function 1: | Fully automatic quality checking; |

| Weight: | 350-500 KG; |

Sipotek Customized Automated Optical Inspection Sorting Machine

1. Model type: T300

2. Machine characteristics: special vibration disc automatic feeding mechanism

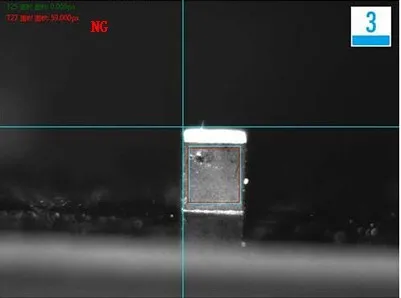

3. Main functions: inspection of length, height, diameter, mixing, deformation, missing material, burr, black spot, scratch, etc.

4. Trial scope: suitable for testing rubber ring, screw, mobile phone accessories, stainless steel, aluminum, plastic and other devices

5. Detection accuracy: the highest accuracy can be up to 1mu

6. Detection efficiency: The highest detection speed can reach 1200 branches per minute.

Design, production, installation and assistance of visual inspection systems since 2002.

Standard, Non-standard customized, inline/online, offline, dimensional measurement, appearance defective inspection.

Please check below our mainly machine components

Machine Parts

Name: Vibration Bowl Feeder

This is an important input mechanism, mostly designed like a bowl. For offline inspection, you will feed the products into the bowl, then they will run and run until being able to stand still one by one with sequence. In this way, they will be ready for inspection.

Machine Parts

Name: Industrial Cameras

Our machine inspection system uses optical image processing system. The cameras are playing an core role since we are visual inspecting by clear and visible images. Which are captured by industrial cameras, with HD, FA optical lenses, and under sufficient light sources. Our cameras are mostly SONY and BASLER.

Machine Parts

Name: Glass Rotary Plate

It's a high speed turntable where all the target are image-captured and quality-inspected. Looking like a platform, it was designed with professional thickness and shape. The targets will be carried on this plate with a high speed setting by the system.

Machine Parts

Name: Operation Section

This is the place where the operator manipulate the machine. There will be an LCD screen display what's inspecting on the way. You can check the defects, the quantity, and on/off the machine, etc.

The machine is composed by different components, but mostly 3 main parts. the input, inspection section and output. The body is compact and space-saving, the installation is easy.

They explains where the inspection starts, how the objects are inspected and where are they loaded.

If you are confused of which is the part and what they are used for, please contact us at any time.

We can be reached by what's app, wechat, skype, emails and phone.

We are focusing on inspection for electronic components, precision hardware, plastic parts, phone screws, magnetic transformers, inductors, rubber plugs, rubber seal rings, washer o rings, button cell caps, wafers, coils, printing tag cards, zippers, punching holes, etc.

If you are manufacturers in these fields, looking for an vision inspection machine, you can send samples and visit our company watching the demos. If your products pass our evaluation, we will report to you with an inspection solution.

Gears & Pinions

>> Inspection requirements

Gear wheel in 6 mm diameters

External appearance inspection

>> Inspection details: missing teeth, stains, damage

1. Bottom appearance, missing teeth

2. Top appearance, missing teeth

Silicone Buttons

>> Product size:

Length 13.8 mm

Width 5.77 mm

Height: 2.99 mm

>> Inspect external appearance & dimensions

>> Inspection details: Size, burr, missing material

Wafer chips

>> Product size:

Length 1.44 mm

Width 1.43 mm

Height 1.65 mm

>> Inspect external appearance & dimensions

>>Inspection details: damage, crack, hole, poor coated

Inductance cores & Transformers

>> Product inspection area:

Inductance parts bottom appearance

Top appearance and dimensional detection

>> Inspection details: damage, missing material, size

Shenzhen Sipotek Technology Co., Ltd.

Since we established 16 years ago, we has been committed to the research, development and manufacturing of image technology and machine vision, with more than 70 senior R&D personnel of machine vision system and industrial automation engineers.

Anhui Sipotek Technology Co., Ltd.

Global specialists in high performance machine vision and vision systems.

Immensely powerful, state-of-the-art automated quality control machine vision inspection systems and machines.

A new generation of class-leading vision system, better in every way. Faster, more efficient and integrated by our experts.

Easy to use, our vision systems are also practical and simple to maintain.

AOI Automated Optical Inspection Application

Sipotek is a professional machine vision inspection robot supplier and manufacturer. Welcome to visit our website and discuss with us online. If you want to visit our company and see how the inspection machine working, please visit our company and let us know in advance so that we can make a good preparation for you.

Sipotek Attend Fairs for Automation Inspection Field

Our machine is designed according to customer's requirement.

Welcome to visit our company!

Before we can design a suitable inspection system for your products, we need to confirm as many details as possible. We will collect all the requirements which will be supportive for our R&D team to do the test and design a solution.

Sipotek is a professional machine vision inspection supplier and manufacturer. Welcome to visit our website and discuss with us online. If you want to make a schedule to visit our company, please let us know in advance so that we can make a good preparation for you. We welcome our customer to plan a visit to our company and watch the machine demo. If you are interested in automated inspection system or machine vision solution, please contact us for more information.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: +86-18617182707

Website: https://www.sipotek.net

1. What's the minimum order quantity(MOQ)?

- 1 machine, small batch and large volumes are acceptable.

2. When can I get the quotation?

- We usually respond within 24 hours on working days receiving your quotation. Then we will discuss the inspection details and requirements as much as possible to design your inspection solutions. After receiving samples for testing and evaluating, a solution will be born and will be forwarded to you with quotation within one week.

3. Which is the safe payment method to trade?

- We accept T/T, LC, Paypal, Trade Assurance and Secure payment on Alibaba platform.

4. How long will it take to produce the machine?

- For standard machine, it will be 15 days for manufacturing.

- For non-standard machine, it will be negotiated customized according to your requirements.

5. What's the shipping method of Sipotek?

- We are able to ship worldwide where Ocean shipping or Air shipping can reach.

- Machines will be packed safely and protectively to ensure you will receive a brand new one.

6. How do you ensure quality control?

- Sipotek is a professional machine vision inspection supplier with 16 years experience of research and develop in this field. We ensure 100% brand new machine production. Our machine is stable and reliable to help you increase quality efficiency.

7. What's the warranty and after-sales service?

- Sipotek warrants all the machines made by Sipotek under normal use of a period of A YEAR after the date of the original purchased. Sipotek will train buyers how to install the machine and how to use the machine for free. We also provide a life-time technical support or software upgrade service.

8. If you have any other questions , please contact us.

-

PCB board packaging vacuum packaging machine is simple to operate and simple to maintain.

-

Multifunctional Universal LED Bulb Assembly Equipment Fully Automatic LED Bulb Making Machine

-

Customized LCD Machine Accessories Glass Rod Quartz Rod

-

Magnetic powder brake

-

SE Series Arise actuators with various thrusts and shocks

-

Mobile Phone Jack Vacuum Coating Back Cover Film Envelope Machine for iPhone SAMSUNG Huawei Honor

-

Mobile phone hydrophobic nano liquid spraying machine

-

Pcb Drill Routing Cnc Machine Pcb Separator Cutting Machine Split Circuit Board Machine

-

85 inch Lcd Led Laptop Laser Screen Panel Repair Machine Laser Welding Solder Repair Machinery Bright Line Laser Repair

-

LED bulb machine light source board glue machine LED bulb machine electrical equipment