downhole mud motor 2.87"

-

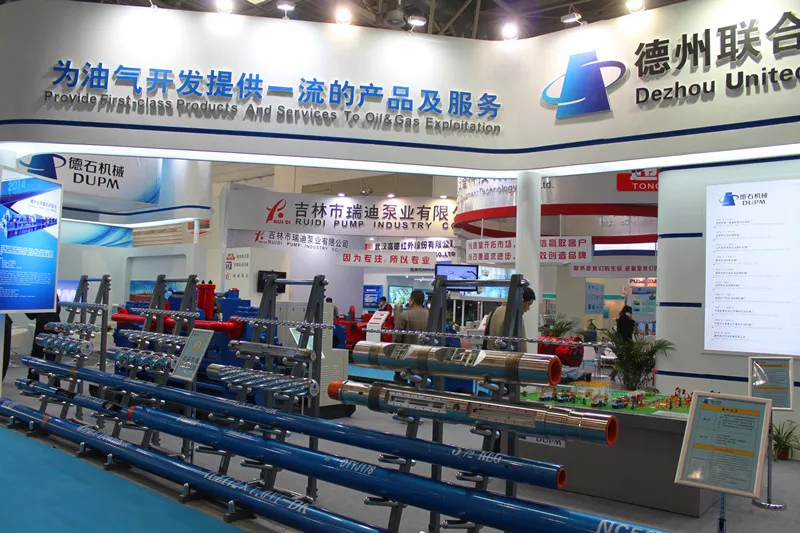

Supplier: Dezhou United Petroleum Technology Corp. -

Region: Shandong, China -

Contact: Mr. Paul Liu -

Price: $5000.00 /set -

Min. Order: 1 set

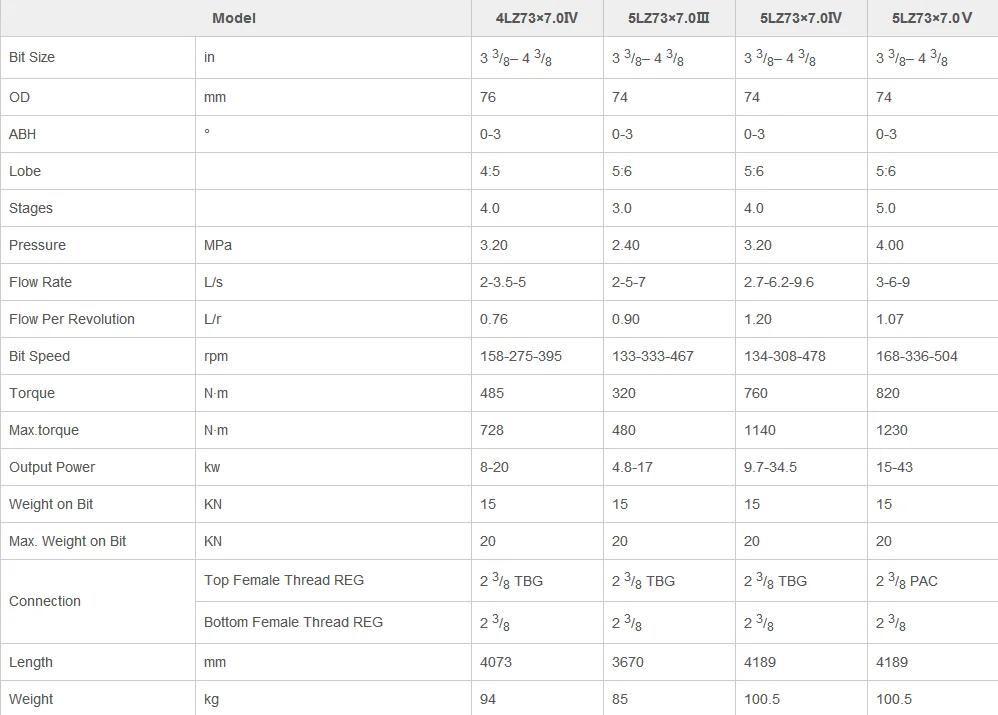

| Weight: | 85kg; | Packaging Detail: | standard export package; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram,Cash; | Length: | 3670mm; |

| Stage: | 3; | Type: | Downhole Motor; |

| Supply Ability: | 400 Set/Sets per Month; | Lobes: | 5:6; |

| ABH: | 0-3°; | Applicable Industries: | Energy & Mining; |

| Model Number: | downhole mud motor 2.87"; | Port: | Tianjin or Qingdao; |

downhole mud motor 2.87"

These motors are designed for continuous tubing and small diameter long well which can provide a good and stable power output performance.

Features:Wide output rage of speed and torque;Good and stable power output performance;Maintenance is simple and cost is low.

Introduction

Model DT down-hole motor is a positive displacement motor.It converts the high fluid power into machinical energy of bit rotation.Downhole motor is widely used in drilling,kick-off,azimuth control,coring,reaming,side tracking and workover for the directional wells,horizontal wells,cluster wells and straight wells of oilfileds and coal mines.In addtion,it is suitable for complex drilling.

Structure of the mud motor.

1)Float assembly or by-pass value assembly

2)Rotor-anti-drop assembly

3)Power section assembly

4)Universal shaft assembly

5)Bearing assembly

Dezhou United Petroleum Machinery Co., ltd produces various sizes of downhole motors for hole size from 1 7/8” to 26”. Popular size are 1 11/16”, 2 1/8”,2 3/8”,2 7/8”,3 1/8”,3 1/2”,3 3/4”,4”,4 3/4”,5”,5 5/16”,5 7/8”,6 1/4”,6 1/2”,6 3/4”,7”,7 1/4”,7 3/4”,8”,8 1/2”,9”, 9 5/8”and 11 1/4”. DUPM is able to provide downhole motors of vertical, single-bend, double-bend and adjustable motors; the hear-resistance temperature ranges are ≤120℃,120-150℃ and 150-180℃; oil-based mud resistance and saturated saltwater mud resistance motors and can independently research and develop and produce various size of uniform thickness downhole motors.

The company has a number of outstanding senior engineers in the design team, and the technologies keep improving aiming at the international level and we have earned more than 30 national patent. We can research and develop and produce various sizes of downhole motors according to customer’s requirement.

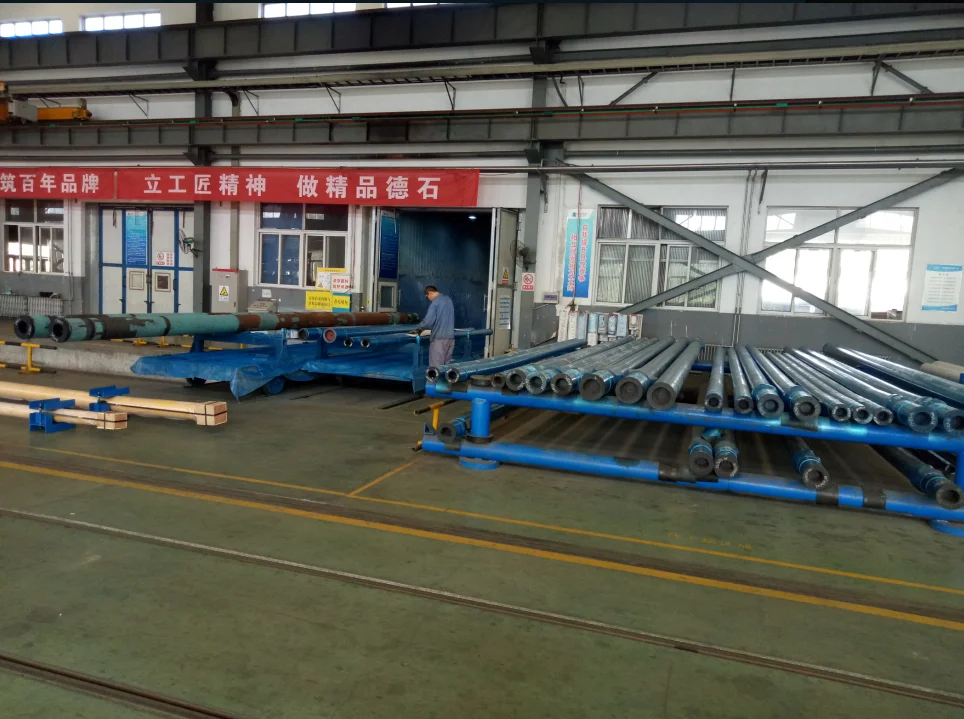

Workshop

Manufacturing Facilities

Packed in wooden case.

Shipment: by sea or by flight or by train.

Purchase Guide

If you want to obtain good effectiveness by using downhole motor, you should take concern not only with its quality, technical property, but also with the application purpose, environmental conditions and its combination as well. So it is very important to make correct selection of the type and composition when purchasing the equipment. Please contact us if you have any questions for selection.

Please fill in the form when you are planning to order the equipment, to ensure correct and rapid provision of our products. So we need to confirm the following information:

1) It is necessary to identify some factors:

A: Both end connection of downhole motor;

B:Structure of steerable motor bend and specific angle;

C:Type of stabilizer for steerable motor;

D: Hollow power section or not;

E: Heat-resistant motor or not;

F: Oil based mud resistant motor or not;

G:Saturated saltwater mud resistant motor or not.

2) Need providing Accessories;

A: Lifting nipple(wellhead or with drilling)

B :Directional collar

3)If possible, please provide the following information for feedback;

A:Name of customers;

B:Location ,purpose and estimated Duration

C:Well bore structure, section to use motor drill, such as the following factors:

Well size and track

Bit model (speed of rotation, torque and WOB)

Bit nozzle pressure drop

Flow rate

Stratal configuration

D :Mud system

Professional After-sales Service are provided oversea. We have a branch in Ahvaz, Iran.

Online sales service:

-

Hot sale matrix drill body PDC well drill 7-1 / 2 inch M223

-

Open the hole HDD 30HA06T547R

-

High quality Factory Price Drilling BI-CENTER MILL drilling bits

-

3-5/8 BP Wireline Setting tool

-

Supplying API casing drilling tools 4 inch pipe drill collars for sale

-

high hardness non magnetic stainless steel drill collar for sale

-

36HA06T537R HDD hole opener

-

TIC tricone drill bit 3"-26" oil well drill bit for sale rock hard bit

-

tricone drill bit steel tooth drill bits 215 .9mm 8-1/2"inch TIC bit IADC211

-

tricone drill bit steel tooth drill bits 445mm 17-1/2"inch

Other Products

-

$35.00 / piece

$35.00 / piece -

$1.00 / piece

$1.00 / piece -

$1.00 / piece

$1.00 / piece -

$8000.00 / set

$8000.00 / set