ELANG Two-stage Compression Screw Air Compressor for CNG Natural Gas

-

Supplier: Elang Industrial (shanghai) Co., Ltd. -

Region: Shanghai, China -

Contact: Mr Jack Cao -

Price: $6000.00 /set -

Min. Order: 1 set

| Drive Method: | Direct driven / Coupling; | Air End: | GHH/Aenzen/ ELANG; |

| Mute: | Yes; | Payment Terms: | L/C,D/P,T/T,Western Union; |

| Insulation Grade: | F; | Condition: | New; |

| Place of Origin: | China; | Exhaust Oil Content: | < 3ppm; |

| Power Source: | AC POWER; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Lubrication Style: | Lubricated; | Application: | General Industrial; |

| Brand Name: | ELANG; | Warranty: | 18 months; |

| Product name: | ELANG Two-stage Compression Screw Air Compressor for CNG Natural Gas; | Packaging Detail: | Standard exporting packing for ELANG Two-stage Compression Screw Air Compressor for CNG Natural Gas; |

| Supply Ability: | 300 Set/Sets per Month ELANG Two-stage Compression Screw Air Compressor for CNG Natural; | Type: | SCREW; |

| Voltage: | 220V/230V/380V/400V/415V/440V/460V/600V/Customized; | Configuration: | Stationary; |

| Port: | Shanghai, any port in China; | OEM / ODM: | Offered; |

| Cooling Method: | Air Cooling /Water Cooling; | Certification: | CE / ISO9001 / TUV / SGS / ASME; |

| Applicable Industries: | General Industry; | Protection Grade: | IP54 /IP55; |

| After-sales Service Provided: | Field maintenance and repair service; |

ELANG Two-stage Compression Screw Air Compressor for CNG Natural Gas

ELANG Two-stage Compression Screw Air Compressor for CNG Natural Gas

Working Pressure: 7 - 12.5bar (100 - 181psi)

Air Delivery: 2.7 - 61.9m3/min

Type of Driving: Direct Driven

Type of Cooling:

Air Cooling/Water Cooling

There are more parameters below.

Description

Two-stage Compression Double Screw Air Compressor, screw rotor adopts a two-stage compression engine, is to use two groups of size is not consistent, reasonable distribution of pressure, lowering the pressure level at each level compression ratio. Reduce the leakage and improve the volumetric, reduce the bearing load, improve the bearing life, prolong the life of the host. The inlet of the main engine adopts the axial inlet, and the intake noise is reduced. Direct drive, high efficiency, low vibration and low noise.

Details

Advantages

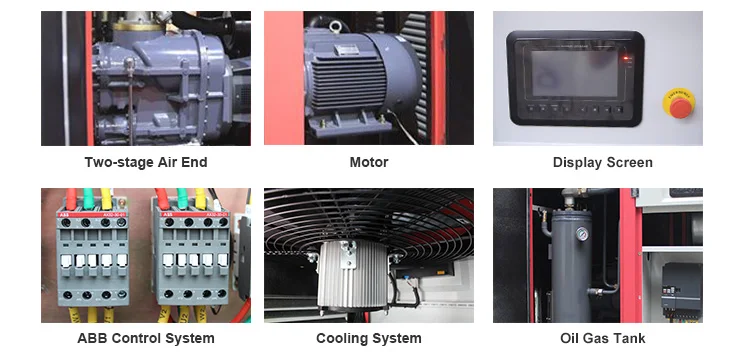

Air End

Two-stage compression compared to single-stage compression,the two compression tends to the most provincial power of the isothermal compression,from the principle,the single-stage compression of the two compression energy saving 5~8%.

Won the award of Level 1 energy Efficiency Grade Certification.

Compared with Level 2 Energy Efficiency GradeSave 10%-15% energy.

Compared with Level 3 Energy Efficiency GradeSave 20%-30% energy.Motor

a)The use of energy-efficient motor,F grade insulation grade,high protection motor,with imported SKF bearings.

b)The capacity of the motor is increased by 1.2,so as to ensure that under the condition of various weather conditions,the load can be loaded without fault operation.Control Panel

LCD HD touch monitor,PLC control ,Human menu interface design.

Can display multi line operation parameters,historical records

Simple operation,inquiry ,convenient maintenance.High Efficient Separation of Oil and Gas System

The oil content of the compressed air of the outlet is only 2ppm by using the three stage method(cyclone separation method,sedimentation separation method and the fine filtration method).

Low Noise Design

A)Selection of large diameter,low speed of the low noise fan: provide large air quantity can effectively reduce the fan noise.

B)Totally enclosed mute type design,accord with international working noise standard.

Specifications

| Model | Working Pressure | Air Delivery | Motor Power | Type of Driving | Type of Cooling | Dimension(mm) | Weight(kg) | Output pipe Diameter | ||||||

| psig | bar | cfm | m3/min | kw/hp | L | W | H | |||||||

| ERC-20SA-II | 100 | 7 | 109.5 | 3.1 | 15/20 | Direct driven | Air Cooling / Water Cooling | 1500 | 950 | 1300 | 1250 | G 1/2 | ||

| 145 | 10 | 106.0 | 3.0 | |||||||||||

| 145 | 10 | 102.4 | 2.9 | |||||||||||

| 181 | 12.5 | 95.3 | 2.7 | |||||||||||

| ERC-25SA-II | 100 | 7 | 127.1 | 3.6 | 18.5/25 | 1500 | 950 | 1300 | 1300 | G 1 | ||||

| 116 | 8 | 123.6 | 3.5 | |||||||||||

| 145 | 10 | 106.0 | 3 | |||||||||||

| 181 | 12.5 | 99.0 | 2.8 | |||||||||||

| ERC-30SA-II | 100 | 7 | 155.4 | 4.4 | 22/30 | 1480 | 900 | 1330 | 950 | G 1-1/4 | ||||

| 116 | 8 | 151.8 | 4.3 | |||||||||||

| 145 | 10 | 127.0 | 3.6 | |||||||||||

| 181 | 12.5 | 120.0 | 3.4 | |||||||||||

| ERC-40SA-II | 100 | 7 | 233.0 | 6.6 | 30/40 | 1650 | 1100 | 1400 | 1100 | G 1-1/2 | ||||

| 116 | 8 | 222.5 | 6.3 | |||||||||||

| 145 | 10 | 173.0 | 4.9 | |||||||||||

| 181 | 12.5 | 148.3 | 4.2 | |||||||||||

| ERC-50SA-II | 100 | 7 | 254.2 | 7.2 | 37/50 | 1650 | 1100 | 1365 | 1100 | G 1-1/2 | ||||

| 116 | 8 | 250.7 | 7.1 | |||||||||||

| 145 | 10 | 204.8 | 5.8 | |||||||||||

| 181 | 12.5 | 190.7 | 5.4 | |||||||||||

| ERC-75SA | 116 | 8 | 441.4 | 12.5 | 55/75 | 2650 | 1500 | 1900 | 3100 | DN50 | ||||

| 145 | 10 | 349.6 | 9.9 | |||||||||||

| 181 | 12.5 | 335.4 | 9.5 | |||||||||||

| ERC-100SA | 116 | 8 | 554.4 | 15.7 | 75/100 | 2650 | 1500 | 1900 | 3100 | DN50 | ||||

| 145 | 10 | 437.8 | 12.4 | |||||||||||

| 181 | 12.5 | 346.0 | 9.8 | |||||||||||

| ERC-120SA | 116 | 8 | 674.4 | 19.1 | 90/120 | 2760 | 1510 | 1950 | 3200 | DN65 | ||||

| 145 | 10 | 547.3 | 15.5 | |||||||||||

| 181 | 12.5 | 437.8 | 12.4 | |||||||||||

| ERC-150SA | 116 | 8 | 819.2 | 23.2 | 110/150 | 2860 | 1890 | 2060 | 4350 | DN65 | ||||

| 145 | 10 | 674.4 | 19.1 | |||||||||||

| 181 | 12.5 | 547.3 | 15.5 | |||||||||||

| ERC-175SA | 116 | 8 | 1002.8 | 28.4 | 132/175 | 2860 | 1890 | 2060 | 4850 | DN80 | ||||

| 145 | 10 | 819.2 | 23.2 | |||||||||||

| 181 | 12.5 | 674.4 | 19.1 | |||||||||||

| ERC-200SA | 116 | 8 | 1182.9 | 33.5 | 160/200 | 3450 | 1930 | 2250 | 6200 | DN80 | ||||

| 145 | 10 | 1002.8 | 28.4 | |||||||||||

| 181 | 12.5 | 819.2 | 23.2 | |||||||||||

| ERC-250SA | 116 | 8 | 1366.5 | 38.7 | 185/250 | 3450 | 1930 | 2250 | 6300 | DN80 | ||||

| 145 | 10 | 1182.9 | 33.5 | |||||||||||

| 181 | 12.5 | 1002.8 | 28.4 | |||||||||||

| ERC-270SA | 116 | 8 | 1493.6 | 42.3 | 200/270 | 3450 | 1930 | 2250 | 6400 | DN100 | ||||

| 145 | 10 | 1366.5 | 38.7 | |||||||||||

| 181 | 12.5 | 1182.9 | 33.5 | |||||||||||

| ERC-300SA | 116 | 8 | 1564.2 | 44.3 | 220/300 | 3450 | 1930 | 2250 | 6800 | DN100 | ||||

| 145 | 10 | 1437.1 | 40.7 | |||||||||||

| 181 | 12.5 | 1366.5 | 38.7 | |||||||||||

| ERC-330SA | 116 | 8 | 1818.5 | 51.5 | 250/330 | 3450 | 1930 | 2250 | 7500 | DN100 | ||||

| 145 | 10 | 1528.9 | 43.3 | |||||||||||

| 181 | 12.5 | 1419.5 | 40.2 | |||||||||||

| ERC-375SA | 116 | 8 | 2002.1 | 56.7 | 280/375 | 3530 | 2280 | 2300 | 8500 | DN125 | ||||

| 148 | 10 | 1638.4 | 46.4 | |||||||||||

| 181 | 12.5 | 1511.3 | 42.8 | |||||||||||

| ERC-420SA | 116 | 8 | 2185.7 | 61.9 | 315/420 | 3530 | 2280 | 2300 | 8700 | DN125 | ||||

| 145 | 10 | 1984.4 | 56.2 | |||||||||||

| 181 | 12.5 | 1638.4 | 46.4 | |||||||||||

| Motor Efficiency Class: Ultraefficient/IE3/IE2 as per your required Motor Protection Class: IP23/IP54/IP55 or as per your required Certification: CE/ISO9001/TUV/UL/SGS/ASME Voltage: 380V/3PH/50HZ/60HZ, 220V/3PH/50HZ/60HZ, 400V/3PH/50HZ/60HZ, 440V/3PH/50HZ/60HZ, 415V/3PH/50HZ/60HZ, 230V/3PH/50HZ/60HZ, dual voltage is also ok | ||||||||||||||

Product Application

| Industrial Equipment Pipelines Oil & Gas Coating Plastics Rubber Blow Molding Shipyard Metallurgy Printing Service Power Plants Oil Refinery | Painting Steel Industry Mechanical Color Sorter Machine Sandblasting Tobacco Factory Shoe Factory Metal Factory Sugar Factory Pneumatic Tools Construction | Packing Railway Head Project Curry Juice Factory Silicon Sealant Production Plant Beverage factory Automotive Industry Tire Repair Factory Furniture Factory Stamping Chili Sauce Factory Small Workshop |

Packaging & Shipping

Certificate

About Elang

| In China air compressor industry, there is such a company, since the last century, dozens of years hard work and always focus on the screw air compressor R&D and manufacturing. All her life is only for one thing, and once charting out a correct direction, she will do this thing more perfect, that is ELANG concentration and persistence. | ELANG group is located in Nanxiang Industrial Development Zone, Jiading District, Shanghai, which is the high-tech enterprises in Shanghai and China's quality service integrity AAA-class corporation. ELANG Group development extends a number of areas, it contains Elang Industrial (shanghai) co.,ltd. Shanghai Elang Machinery co.,ltd etc. | ELANG owns a whole set of mature production technology standards, from R&D, design to production and assembly, ELANG establish the standard production line supported by technology. ELANG production is checked step by step strictly to ensure that each process in a scientific and standardized seamless docking. |

Exhibition

FAQ

Q1.Why customer choose us?

A:ELANG INDUSTRIAL (SHANGHAI) CO., LTD., with 18 years old history, we are specialized in Rotary Screw Air Compressor. Germany Standard and 10years exporting experience help us won more than 50 loyal foreign agents. We warmly welcome your small trial order for quality or market test.

Q2.Are you a manufacturer or trading company?

A:We are professional manufacturer with big modern factory in Shanghai,China.

Both OEM & ODM service can be accepted.

Q3.What’s your delivery time?

A:Generally 3 to 7 days, if urgently order, pls contact our sales in advance.

Q4.How long is your air compressor warranty?

A:One year for the whole machine and two years for screw air end, except consumble spare parts.

Q5.How long could your air compressor be used?

A:Generally, more than 10 years.

Q6. What's payment term?

A: T/T, L/C, D/P, Western Union, Paypal, Credit Card, and etc.

Also we could accept USD, RMB, Euro and other currency.

Q7.How about your customer service?

A:24 hours on-line service available. 48hours problem sovled promise.

Q8.How about your after-sales service?

A:1. Provide customers with intallation and commissioning online instructions.

2. Well-trained engineers available to overseas service.

3. Worldwide agents and after service avaiable.arrange our engineers to help you training and installation.

Related Products

-

4KW 5.5 HP 80L 100L 200L 500L piston belt driven mzb brand industrial air compressor

-

Newest Promotion Portable Piston Air Compressor A RI-0251 2.5HP 50L Compressor Piston Air CE

-

small air compressor 110v 220v electric 1hp 2hp 3hp portable horizontal direct drive

-

Belt piston air compressor W-0.36/12 12 bar 4hp 3kw for sale

-

portable mini compressor with air brush for composition DH06K (CE/GS)

-

Best Factory Price 24L 2.5HP Direct Drive Portable Air Compressor

-

HENGKE 300L V2105 industrial air compressor with CE GS

-

Excellent design compressor High quality 220V portable air compressor

-

China factory high quality portable 50 liters air compressor

-

Air compressor

Other Products

-

$500.00 / set

$500.00 / set -

$580.00 / set

$580.00 / set -

$2500.00 / unit

$2500.00 / unit