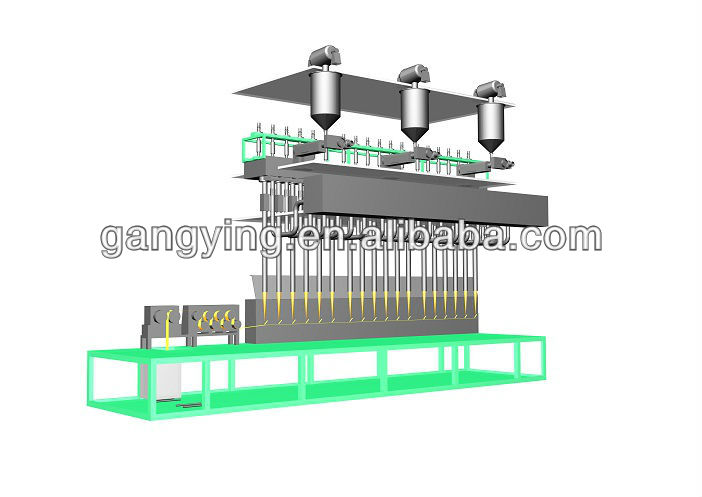

Factory Outlet Stack Machine for multiple Fiber Production Machinery Line

-

Supplier: Zhangjiagang Gangying Industry Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Kai Chen -

Price: $3000.00 /set -

Min. Order: 1 set

| Type: | Fiber; | key words: | Hollow Conjugated; |

| Packaging Detail: | standard wooden packing; | Application: | Fiber making; |

| Certification: | ISO 9001, CE; | Power(W): | 400-1200KW; |

| Production Capacity: | 10TPD-100TPD; | Supply Ability: | 40 Set/Sets per Year; |

| Voltage: | 415V/380V/240V; | Condition: | New; |

| Production Specification: | 6D to 15D; | Advantage: | High Efficiency; |

| usage: | High Quality Cloth; | Port: | Zhangjiagang, China; |

| Place of Origin: | Jiangsu China; | COLOR: | customization; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Warranty: | 24 months; |

| Function: | Automatic; | Brand Name: | Gangying; |

| Weight: | 50Tons-100Tons; | MOQ: | 1set; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | purpose: | widely used in fabric pleating; |

multiple Fiber Production Machinery Line

multiple Fiber Production Machinery Line is used the recycled PET flakes and virgin chips to produce the polyester staple fiber; it is a flexible production line. It can produce solid polyester staple fiber (PSF) and 3-dimensional conjugated fiber (HCF) (including dope dyed fiber), the specification from 1.5D to 20D. The capacity can be from 3000MT/year to 30,000MT/year.

Our machines had been exported to India, Turkey, Korea, USA, Honduras, Thailand, Vietnam, Iran, Philippine and so on totally more than 140 product lines.

We warmly welcome your coming to our company. We hope we have the opportunity to do business with you.

Process flow of the multiple Fiber Production Machinery Line

Spinning Line:

Vacuum Dryer -> Hopper -> Screw Extruder -> Filter -> Spin Beam (Meter Pump System, Spin Pack, Spinneret) -> Quenching Unit -> Interfloor Duct -> Draw-off Wall -> Capstan Roller -> Sunflower Gearing unit -> fiber can traverse system

Draw Line:

if 2-Dimensional Hollow Fiber:

Can Creel -> Inlet Thread Guide -> Tow Guide Stand -> Dipping Bath -> 1st Draw Stand -> Draw Bath -> 2nd Draw Stand -> Draw Steam Chest -> 3rd Draw Stand -> Tow Stacker -> Crimper Steam Box -> Crimper -> Tow Conveyer -> Relaxer -> Tow Tension Stand -> Cutter -> Chain Plate Conveyor -> Baling Press

if 3-Dimensional Hollow Fiber:

Can Creel -> Inlet Thread Guide -> Tow Guide Stand -> Dipping Bath -> 1st Draw Stand -> Draw Bath -> 2nd Draw Stand -> Draw Steam Chest -> 3rd Draw Stand -> Tension Control Device -> Tow Stacker -> Crimper Steam Box -> Crimper -> Silicon Oil Sprayer -> Tow Tension Stand -> Cutter -> Fiber Spreader -> Fiber Leveler -> Relaxer -> Chain Plate Conveying system -> Baling Press

Information about multiple Fiber Production Machinery Line

We provide high efficiency overseas installation and commissioning. Usually in two months, the whole production line can be operating with no error.

Our service about multiple Fiber Production Machinery Line

With delivery time of 6 months.

Engineers overseas installation and commissioning is available.

GangYing Industry has a history near 30 years of recycling fibre production line manufacturing and is now a professional

manufacturer producing both solid and hollow conjugated recycling staple fibre production lines and capable in technique supporting. We are dedicated to meet the needs of our customers and develop and design various specific products according to the requirements of customers and provide superior services such as workshop design, staff training, equipment installation and adjustment.

-

Cottonseed lint removal and cleaning machine/cottonseed lint removal machine/cottonseed sawtooth lint removal separator

-

Machine for removing cotton seeds

-

Cotton gin complete set sawtooth gin production line seed cotton gin

-

Seed Processing Roll Saw Cotton Gin

-

Cotton Saw Gin & Washer Used Cotton Ginning Machinery Prices

-

150kg/h cottonseed lint removal machine/cheap cottonseed saw tooth hair removal machine hot sale

-

Automatic cotton removal separator gin cleaning machine price

-

saw mill, cotton gin, cotton gin mill

-

ginning machine ginning machine ginning machine MY96

-

small seed cotton gin cotton fiber trial testing machine cotton seed extracting machine

Other Products

-

$300.00 / set

$300.00 / set -

$3000.00 / set

$3000.00 / set