100kg/hour Mini Laundry Toilet Bar Soap Making Machine Price Bath Soaps Stamping And Cutting Machinery

-

Supplier: Zhengzhou Hongle Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms zhimei liu -

Price: $24500.00 /set -

Min. Order: 1 set

| VOLTAGE: | Custom-tailor; | Keywords: | Bath Soaps Stamping And Cutting Machinery; |

| Usage: | bar soap making machine; | Warranty: | 2 years; |

| Brand Name: | hongle; | Package Type: | wooden case for 100kg/hour Mini Laundry Toilet Bar Toilet Soap Making Machine Price Bath Soaps Stamping And Cutting Machinery; |

| Application: | mini soap making machine; | Capacity: | CUSTOMIZED; |

| After-sales Service Provided: | Video technical support,Online support; | Item name: | Hotel Soap Production Line; |

| Finally products: | soap; | Type: | Tranparent Soap making machine; |

| Function: | soap making machine price; | Product name: | Laundry Toilet Bar Soap Making Machine Price; |

| Product Type: | Toothpaste; | Selling Units: | Single item; |

| Single package size: | 1000X200X100 cm; | Place of Origin: | Henan China; |

| Applicable Industries: | Hotels,Garment Shops,Manufacturing Plant,Food & Beverage Factory,Restaurant,Food & Beverage Shops; | Single gross weight: | 5,500 KG; |

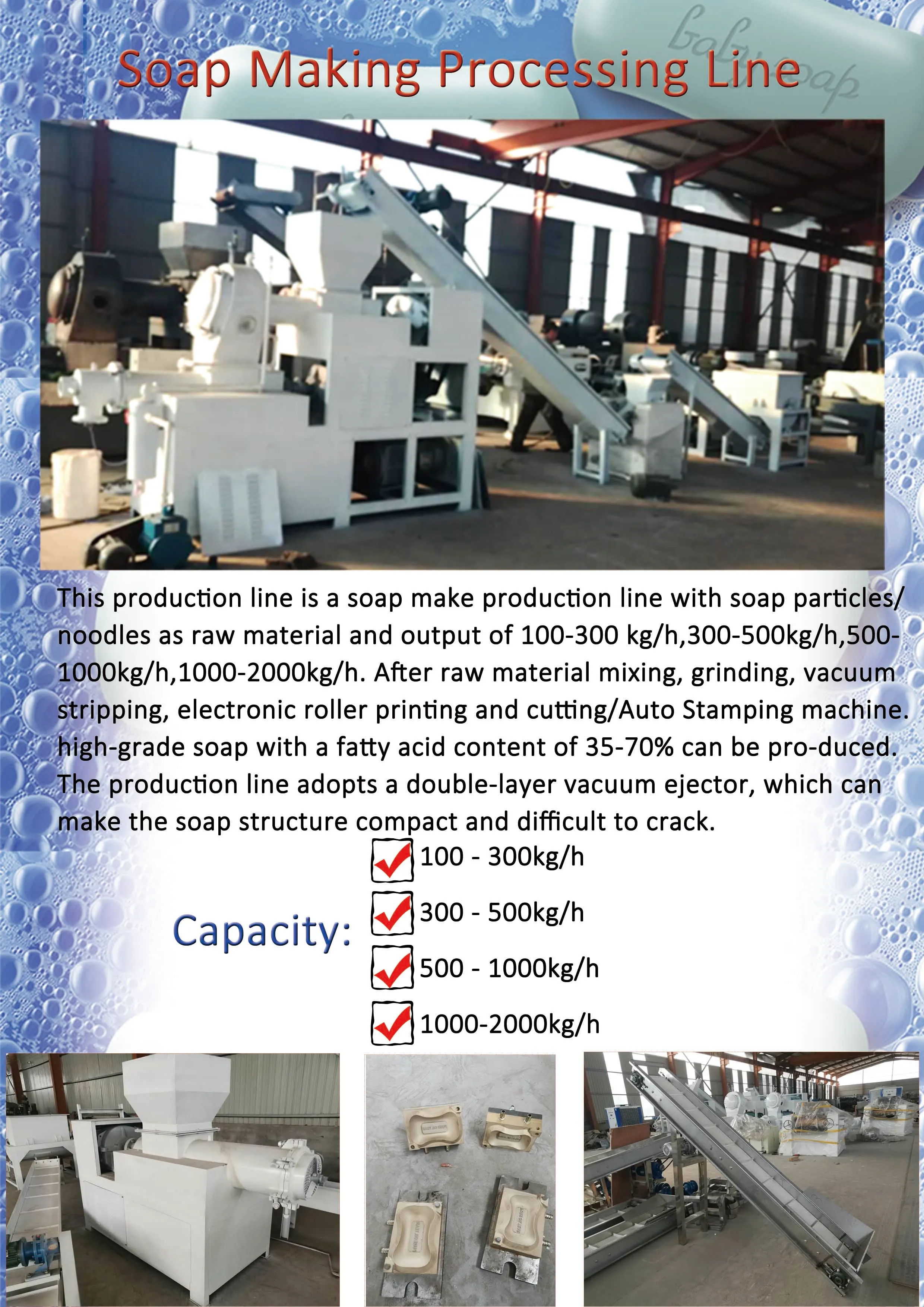

100kg/hour Mini Laundry Toilet Bar Toilet Soap Making Machine Price Bath Soaps Stamping And Cutting Machinery

Intruduction of 100kg/h Mini Soap Making Machine Price

This soap production line regard soap noodles as raw materials or palm oil .The production starts with mixing soap noodles or palm oil . Then the mixed soap noodles enters in the three roller mill by conveyor belt, where soap thin sheets are made. The soap thin sheet then converted into desired long strip soap by the plodder machine.Then the long strip soap are cut into the soap bars required size by cutting machine(there are two kinds of cutting machine.One is mechanical.The other is automatic).Finally, the soap bars gets packed by packing machine if needed.

description of 100kg/h Mini Soap Making Machine Price

a. This system can continuously produce laundry soap, compound soap, industrial soap and others;

b. The production line is mainly consisting of oil refining, saponification, vacuum drying and extrusion;

c. Only when the crystal form of soap is tiny, the soap become fine and smooth. The vacuum drying system can make the soap to form tiny and compact crystal texture which is mainly in the shape of β base;

d. When you produce fatty acid products( laundry soap, compound soap and industrial soap), the fatty acid content is usually 49%, the vacuum degree of the system is about of 740 mmHg, the temperature of soap base is 85 0C, vacuum dewatering is about 4%, you can take 53% fatty acid.

Material needed of 100kg/h Mini Soap Making Machine Price:

Oil or fat of plant or animal (palm oil, coconut oil, tallow oil, etc.), caustic soda (NaOH), sodium-chloride (NaCl), sodium silicate, pigment, etc.

Production process of 100kg/h Mini Soap Making Machine Price:

Mix and melt oil --> Saponification --> Vacuum drying --> Soap noodle --> Grinding --> Vacuum Plodder (extruding) --> Cutting.

Main Machines involved for 100kg/h Mini Soap Making Machine Price

This production line mainly contains :

1. saponification equipment,

2. drying plant,

3. double sigema mixer,(Used for mixing soap noodles.)

4. refiner, Three roller mill, (Used for grinding soap noodles into thin sheets. )

5. duplex vacuum plodder(Extruder) Machine ( Used for molding the sheets into long strip soap of required shape. )

6. water chiller,

7. electronic cutter,( Used for cutting the long strip soap into soap bar that is desired size )

8. stamping machine,

9. freezer,

10.belt conveyors,

11. electric control panel etc.

Available complete set of 100kg/h Mini Soap Making Machine Price

1)capacity: 100—500KG/Hour

2)capacity: 600—1000KG/Hour

3)capacity: 1200—1500KG/Hour

4)capacity: 1500—2000KG/Hour

picture display :

Related Products

PACKAGE:

Standard export carton packing, fit for multiple handing and long distance marine shipping.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

1) When can I get the price?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

2) How do you make your price?

We make the price according to our comprehensive costing. And our price will lower than the trade company because we are manufacture.You will get competitive price and better quality.

3) Can you guarantee your quality?

Of course. We are the manufacture factory. More important, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

4) How long does the whole procedure being worked out?

After you place a order,the production handling time is about 30-45 days. We need 7 days to prepare all the stuff then 30 days for manufacturing.

5) What about the transportation and delivery date?

Normally we use shipment to transprot the goods.It is about 25-40 days.It also denpends on which coutry and port you are. If there are some emergencies we can send the goods via air express, as long as you afford the traffic expense.

-

CANMAX fully automatic small-scale soap making machine-made soap machine solid soap production line

-

Fully automatic complete soap finishing production line laundry soap making machine manufacturer price

-

Soap Refining Machine Pressing Machine for Sale Soap Refining Machine Pressing Machine Mini Pressing Machine Soap Maker

-

Automatic Soap Sealing Machine Soap Sealing Molding Machine

-

akd wax 1840 | alkyl ketene dimer akd wax price | alkyl ketene dimer akd wax TK

-

Adjustable Manual Wood Soap Knife Cutting Tool for Handmade Soap Making and Packaging

-

Fully Automatic Laundry Soap Bar Making Machine Laundry Powder Soap Making Machine Price

-

Small Corn Peanut Seeder Manual Peanut Seeder Push Seeder For Sale

-

Soap bar press machine, bar soap machine, soap finished line

-

Detergent Soap Layering Plant Exporter

Other Products

-

$180.00 - $220.00 / set

$180.00 - $220.00 / set -

$9000.00 / set

$9000.00 / set -

$2150.00 - $2300.00 / set

$2150.00 - $2300.00 / set -

$430.00 / set

$430.00 / set -

$9000.00 / set

$9000.00 / set -

$2200.00 / set

$2200.00 / set -

$700.00 / set

$700.00 / set -

$1850.00 / set

$1850.00 / set -

$5050.00 / set

$5050.00 / set