Q3710 hook type shot blasting machine of ANTAI brand

-

Supplier: Qingdao Antai Heavy Industry Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr yan Ji -

Price: $7000.00 /set -

Min. Order: 1 set

| Dust collector: | bag filtering type; | Certification: | CE/ISO9001; |

| Condition: | New; | Use: | Burnishing,Container / Bottle Cleaning,Deflashing,Degreasing,Descaling / Stripping; |

| Port: | Qingdao prot, China; | Color: | blue for main body, yellow for warning parts; |

| Supply Ability: | 180 Set/Sets per Year; | Packaging Detail: | Standard Containers; |

| Cleaning Process: | abrasives such as steel shot and grit; | Industry Used: | casting. structural, nonferrcus alloy parts; |

| Place of Origin: | Shandong China; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Brand Name: | Antai; | Machine Type: | Abrator; |

| Feature: | Critical Cleaning / Residue Free,Rust / Corrosion Inhibitor; | separation mold: | full curtain wind selection type; |

| Material: | Metal / Coil; | Payment Terms: | L/C,T/T; |

| Dimension(L*W*H): | Customised; | Cleaning Type: | Clean-In-Place (CIP); |

| Fuel: | Electric; |

Q3710 hook type shot blasting machine of ANTAI brand

1. Product description

Hook Type machines are the most flexible machine types. They are split into Batch Type Machines where one batch of parts moves in, starts rotating, gets blasted and moves out, and Continuous Type Machines where the machines are equipped with a monorail system that moves the parts continuously through the machine.

Q37 series hook type airless shot blast cleaning machine is mainly used for surface cleaning and strengthening of steel structural parts, castings, aluminum alloy parts and other spare parts. It is widely used in foundry, mechanical and steel industry.

It has following advantages: no pit, double hook without rail exchanging, compact structure, and high productivity.

2. Technical parameter

Model | Hook | Max. loading weight of single hook | Blasting capacity | Lifting capacity of elevator | Separating capacity of separator | Air volume |

- | - | Kg | Kg/min | T/h | T/h | m³/h |

Q376 | Double hook | 500 | 2x120 | 15 | 15 | 5000 |

Q378 | Double hook | 800 | 2x200 | 22 | 22 | 8000 |

Q3710 | Single hook | 1000 | 2x250 | 30 | 30 | 9000 |

QD3710 | Double hook | 1000 | 2x250 | 30 | 30 | 9000 |

Q3720 | Double hook | 2000 | 3x250 | 45 | 45 | 15000 |

Q3730 | Double hook | 3000 | 3x250 | 45 | 45 | 15000 |

Q3750 | Single hook | 5000 | 4x250 | 60 | 60 | 18000 |

Q37100 | Single hook | 10000 | 5x300 | 100 | 100 | 20000 |

3. Feature

1. Construction free of pit, convenient installation, reduction of investment cost;

2. Compact structure, high efficiency, good cleaning quality, working in safety and running in stable;

3. With double-hook, independent of working each other and non-interacting, improving of production efficiency, the sling takes advantage of planet basis, that is, rotation and revolution happened at the same, so treated parts will not exist at male and female face;

4. The secondary dust removal (vortex de-dusting, bag filter),with large air suction capacity, de-rusting and filtering to clean, exhaust emission complies with environmental standard.

3. Cleaning effect

NOTICE:

According to your requirements,the most suitable machines will be designed for your workpieces please indicate the folloing details.

1.what kind of workpiece will you clean ?

2.The workpiece size,length ,width and height of maximum workpiece?

3.How many workpiecs do you want to clean per day ?

Based on this question,the detailed technical proposals will be sent to you for reference.

Detailed pictures

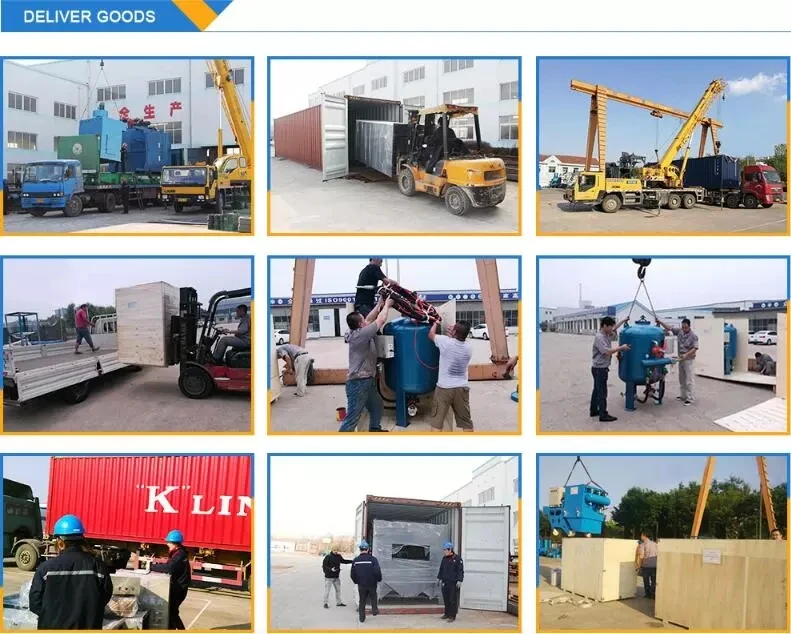

Packing&shipping

1.Equipment painting completed before shipment, With Stretch film to avoid rub off the surface paint, It can used wooden cases packaging according to users requirements.(Key parts such as electric cabinet with shockproof packaging material and then packed in wooden cases. )

2. We have 15 experienced engineers, With 108 skilled workers insure good quality of our machines and prompt delivery.

3.Meanwhile our company has a long-term cooperation with ACL, CSCL, CCNI, CNC, COSCO etc insure the goods to the port on time.

Our service

1. Our engineers can work separately according to the requirements of design for clients of the equipment. and send a customer confirmation to help customers to save costs.

2. During the manufacture of the equipment, we photograph product production progress, and sent to the customer to track the progress.

3. The goods hair go, we will send the original documents for the customer (such as packing list, bill, CO, Form E, Form A, Form F, Form M, B/L etc.)

4. We can provide customers with free English foundation drawing, installation drawings, manuals, maintenance manuals and parts drawings.

5. We can send our engineers to installation and debugging overseas, and free training of operators and maintenance workers.

6. We have a set of After-sales service system, A ID will be sent to each customer, they can log in this system that view all information to buy equipment and parts by it. We provide 24-hour online consultation.

Company information

Qingdao Antai Heavy Industry Machinery CO., LTD was founded in 2003, is located in the convenient transportation and beautiful scenery Huangdao.

1.Company mainly produces shot blasting machine, shot blasting cleaning equipment and sand producting machine, molding machine, environment dedusting machine and so on more than 30 kinds of products.

2.Eight experienced engineers to consider every possibility for customers.

3.Three of them has over 27 years knowledge of shot blasting technology.

4.3D software for auxiliary design. Show every design details in front of you.

5.Experienced technicians for production, installation, commissioning & service.

6.Successfully passed the quality management system certification ISO9001: 2000 and CE.

7.All machining parts out sourced from professional CNC machining company with strict quality control procedure.

8.Own foundry to produce special material spare parts for our machines.

-

Q32 series portable drum-type crawler shot blasting machine/shot blasting machine/equipment

-

Shot blasting machine for metal bottles Large hook type shot blasting machine for metal bottles

-

Q376A Compact rotating suspended double hook wheel shot blasting machine for aluminum rim cleaning

-

Shot blasting machineCrawler type shot blasting machineCrawler type shot blasting machineProduct display

-

Direct Drive Shot Blasting Spare Parts Wheel Turbine Shot Blast Machine

-

spare parts of impact machinery

-

PSBC990 Cabinet is suitable for sandblasting engine parts, wheels, gearboxes, etc., new sandblasting cabinet

-

Q37 double hook wheel rim shot blasting machine

-

Dust-free sandblasting db150, db225, db500, db800, db1500, db3000 portable sandblasting machine

-

Dust-free sandblasting equipment/dust-free sandblasting machine

Other Products

-

$1500.00 / set

$1500.00 / set