Laundry soap making machine for detergent/ toilet soap

-

Supplier: Guangzhou Lianhe Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Maria Wang -

Price: $3200.00 /set -

Min. Order: 1 set

| Warranty: | 1 year; | Port: | Guangzhou Port, China; |

| Supply Ability: | 32 Set/Sets per Month; | Mixing speed: | 0-65 R/min; |

| Heating method: | Electric/Steam Heating; | Place of Origin: | Guangdong China; |

| Function: | Heating, Cooling, Mixing, Homogenizing, Vacuum; | Brand Name: | LH; |

| Jacket Design : | Conventional Jacket; | Application: | Cosmetic,food, pharmacy,chemical; |

| Capacity: | 5-6000L; | Packaging Detail: | Packed in wooden case for long distance shipping. Quality is the First!!; |

| Voltage: | 220V/380V/440V/Customized; | Homogenizing speed: | 0-3600RPM; |

| Machine Material: | SUS316L/SUS304/SUS304; | Applicable Industries: | Manufacturing Plant,cosmetic production; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; |

| Heating Temperature: | Room temperature- 120°C; | Product Type: | Soap; |

Laundry soap making machine for detergent/ toilet soap

| Model | Effective | Stirrring power and speed | Homogeneous power and speed | Heating power | |||

| Capcity | KW | R/MIN | KW | R/MIN | Electric heating | Steam heating | |

| PMC-50 | 50 | 0.75 | 0-65 | 3 | 3600 | 6 KW | Steam heating energy conservation and environmental protection, selected according to need |

| PMC-100 | 100 | 1.5 | 0-65 | 1.5 | 3600 | 12 KW | |

| PMC-150 | 150 | 1.5 | 0-65 | 1.5 | 3600 | 12 KW | |

| PMC-200 | 200 | 1.5 | 0-65 | 3 | 3600 | 18 KW | |

| PMC-300 | 300 | 1.5 | 0-65 | 3 | 3600 | 18 KW | |

| PMC-500 | 500 | 2.2 | 0-65 | 4 | 3600 | 27 KW | |

| PMC-1000 | 1000 | 4 | 0-65 | 7.5 | 3600 | 36 KW | |

| PMC-1500 | 1500 | 4 | 0-65 | 11 | 3600 | 45 KW | |

| PMC-2000 | 2000 | 5.5 | 0-65 | 11 | 3600 | recommed steam heating | |

| PMC-3000 | 3000 | 7.5 | 0-55 | 15 | 3600 | ||

| PMC-5000 | 5000 | 11 | 0-55 | 22 | 3600 | ||

| The parameters for reference ONLY, all the machines can be customized accordingly. | |||||||

We have over 24-year experience in manufacturing homogenized mixing machine such as making shampoo,liquid soap,washing lotion etc viscosity and our engineers with 7-Year overseas service experience can be sent to the site for final Installtion and Maintain.

The Standard Capacity is 50L-5000L.However,we also made the small scale and middle scale capacity.

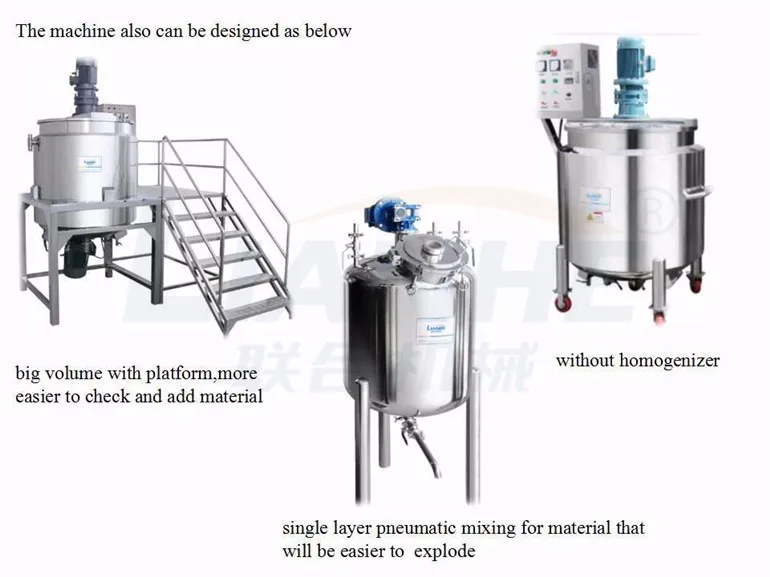

PMC soap producing machine ( blending tank) is mainly suitable for preparation of liquid detergents.Such as cleanser essence, shampoo and shower cream etc.). Integrating blending, dispersing, heating and cooling etc. functions, the machine is an ideal device for liquid preparation in various factories.

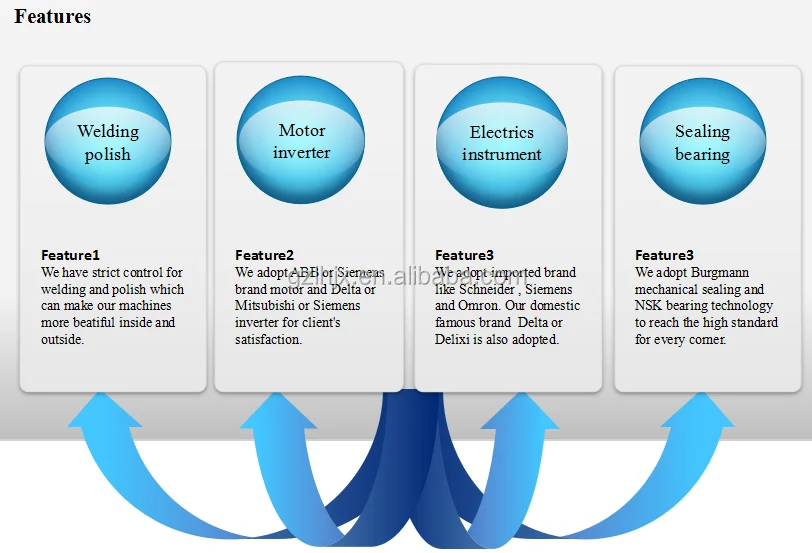

Performance & feature

1, High speed disperser. Might mixing and disperse viscously, solid and liquid etc. Various kind of raw

material will be dissolve which is such as AES, AESA LSA, during liquid production which can save

energy consumption and shorten production the and shorten production period consumption and shorten

production the and shorten production period.

2, Main adopts stepless timing device which reduce babble occur under low temperature and high viscosity condition less air bubble will be formed

3, Finished products can be discharged by Disc-valve or suitable to all liquid wash products.

<<Click here to customize your product details >>

- Guarantee: 1-2 years

- 24 hours Network technical support

- Oversea engineering Service

- Spareparts for consumables

- Manufacture Factory visit available

- Long-term maintaining

-

CANMAX fully automatic small-scale soap making machine-made soap machine solid soap production line

-

Fully automatic complete soap finishing production line laundry soap making machine manufacturer price

-

Soap Refining Machine Pressing Machine for Sale Soap Refining Machine Pressing Machine Mini Pressing Machine Soap Maker

-

Automatic Soap Sealing Machine Soap Sealing Molding Machine

-

akd wax 1840 | alkyl ketene dimer akd wax price | alkyl ketene dimer akd wax TK

-

Adjustable Manual Wood Soap Knife Cutting Tool for Handmade Soap Making and Packaging

-

Fully Automatic Laundry Soap Bar Making Machine Laundry Powder Soap Making Machine Price

-

Small Corn Peanut Seeder Manual Peanut Seeder Push Seeder For Sale

-

Soap bar press machine, bar soap machine, soap finished line

-

Detergent Soap Layering Plant Exporter

Other Products

-

$16000.00 / set

$16000.00 / set -

$1100.00 / set

$1100.00 / set -

$1000.00 / set

$1000.00 / set -

$580.00 / set

$580.00 / set