Bow Type Screw Pin Small Stainless Steel Shackle

-

Supplier: Shanghai Jian & Mei Industry And Trade Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Xarella Huang -

Price: $0.10 / >=1000 pieces -

Min. Order: 1000 pieces

| Finish: | Zinc plated, hot dip galvanizing etc.; | Material: | Carbon steel,stainless steel etc.; |

| Application: | Heavy Industry,Mining,General Industry; | Name: | European Type Bow Shackle; |

| Material: | Carbon steel; | Model Number: | Bow Shackle; |

| Place of Origin: | Shanghai China; | MOQ: | 2000KGS; |

| Type: | European type /US type; | Shackles type: | Bow Shackles; |

| Brand name: | JM; | Supply Ability: | 500 Ton/Tons per Month European Type Bow Shackle; |

| Type: | European Type; | Function: | Lifting; |

| Port: | Shanghai; | Technology: | forging; |

| Color: | Self color/red/green,etc; | Measurement system: | Imperial (Inch); |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Surface Treatment: | Galvanized; |

| Shape: | Bow; | Shackles pin type: | with screw collar pin,with safety bolt pin,with square head screw pin; |

| Certification: | ISO 9001:2008; | Brand Name: | J&M; |

| Packaging Detail: | European Type Bow Shackle packing: Neutral Package or according to the Customers' Demand; |

European Type Bow Shackle

SPECIFICATION | ||

Bow Shackle |

| |

type: | European type /US type | |

color: | Self color/red/green,etc | |

Material: | Carbon Steel, Alloy Steel, Stainless Steel | |

finish: | Zinc plated, hot dip galvanizing etc. | |

function: | Lifting | |

Finish: | Plain, Zinc Plated(Clear/Blue/Yellow/Black), Black oxide, Nickel, Chrome, H.D.G.,Teflon | |

| ||

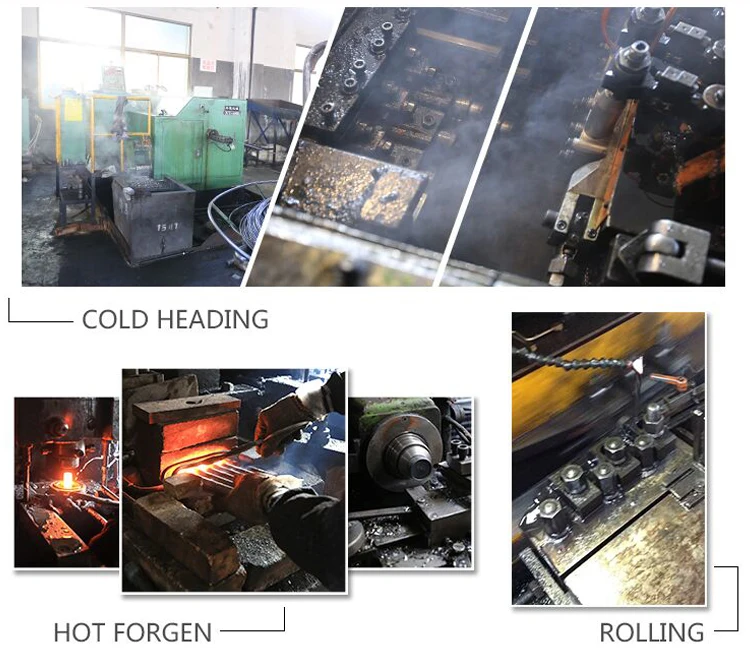

Shanghai Jian & Mei Industry and Trade Co., Ltd. is well equipped with various multi-station cold heading machines and high-medium frequency heating machines imported from Taiwan. JM can manufacture all kinds of fasteners of various head types with the specifications from M6- M56,1/4-2”in diameter, 20-1500 (1”-60”) in length, from Class 4.8 to 12.9 and from A429 Grade 2-8.

We are also capable of providing various surface surface treatment processes, including white zinc plating, blue zinc plating, yellow zinc plating, black zinc plating, blackening phosphorating, nickel plating, hot dip galvanization, DacroMat, Magni and so on. We can process carbon steel, stainless steel, aluminum and copper. According to the drawings or samples provided by customers, we will develop the optimal and cost-effective design and processing combination with cold heading, hot heading, stamping and turning so as to reduce customer’s procurement costs.

We are also capable of providing various surface surface treatment processes, including white zinc plating, blue zinc plating, yellow zinc plating, black zinc plating, blackening phosphorating, nickel plating, hot dip galvanization, DacroMat, Magni and so on. We can process carbon steel, stainless steel, aluminum and copper. According to the drawings or samples provided by customers, we will develop the optimal and cost-effective design and processing combination with cold heading, hot heading, stamping and turning so as to reduce customer’s procurement costs.

The production management of our company strictly complies with ISO9001:2008 system. All our products are subjected to strict test and inspection in each process by the workers periodically, starting from the raw materials delivered to the factory.

They also receive various tests and inspections at the JM quality center before shipment. We have a variety of advanced quality testing equipment, such as tensile testing machine, hardness tester, metallographic microscope, salt spray tester and go-no go gauges etc.

They also receive various tests and inspections at the JM quality center before shipment. We have a variety of advanced quality testing equipment, such as tensile testing machine, hardness tester, metallographic microscope, salt spray tester and go-no go gauges etc.

Each batch of exported products are identified with a unique batch number in the Finished product testing report and steel mill raw material quality inspection report.

The products passing the final inspection can be transferred for packaging. We will choose the most suitable packaging materials according to the product shape before shipment.

| FAQ about QC |

1.Do you inspect the raw material? |

Each batch of materials is carefully tested by inspector on apperance, raw material defects, wire drawing size etc. and the testing result is filed in computer. All the checmical composition as well as material warranty documents of raw materials is spot checked. |

2.Do you inspect the goods during the production? |

Inspector test each process according to the order and the corresponding product standard, each process has corresponding operation instruction. All the test result is filed in the corresponding computer daily. Mechanical properties are filed in paper documents. |

3.How do you control each batch goods? |

Statistician keep recording and filing all batch of the incoming products, noted with contract No., model, size, quantity, weight, surface color etc. |

4.Will you ship the unqualified goods? |

Concerning to abnormal occurrence or unqualified products: Unqualified products processing sheet is reported to QC dept. by inspector. The reworking will be done after QC workers come up with solutions and suggestions. |

5.How do you manage your files? |

All the documents or customer orders is given out by designated personnel. The drawings and exterior documents are given out and recorded by QC department. |

6.Can we get the inspection certificate? |

A Unified test report presented by specific worker is delivered together with the finished products. |

7.How do you keep your testing equipment? |

Ⅰ. Heavy testing equipments: tensile machine, charpy impact tester; hardness tester; thread check gauge, plug gauge, vernier caliper, micrometer, pitch diameter micrometer, dial caliper, digimatic caliper etc. are all sent to be tested and adjusted in qualified professional company for once annually. |

Ⅱ. Ring guage is tested and adjusted by proof-reader in company monthly; hardness tester is only applied after the testing by on-duty inspectors each day. |

8.What’s the shipping process? |

Ⅰ. For LCL cargos, we arrange reliable logistics company to drive them to the forwarder agent’s warehouse. |

Ⅱ. For FLC cargos, the container directly go to the Factory loading. Our professional loading workers, accompanied with our forklift workers arrange the loading in good order even on the condition that daily loading capacity is overloaded. |

Ⅲ. Our professional data management is a guarantee of the real-time update and the unification to all the electrical packing list, invoice. |

-

Hot selling galvanized G209 threaded pin chain shackle

-

Marine Rigging 316 Stainless Steel Quick Release Fixed Eye Swivel Eye Buckle Ring

-

D Ring Shackle Wholesaler Stainless Steel American Chain D Ring Shackle With Screw Pin

-

Factory-made high-strength quick release zinc alloy metal buckle

-

High Quality OEM Custom Forged U Shackle 25 Tons D Shackle Safety Lock Pin

-

Stainless steel shackle hook for processing poultry shackles

-

Factory direct sale galvanized steel forged screw pin anchor bow lifting ship rigging shackle

-

D/U type anchor shackle Galvanized steel alloy anchor shackle

-

Solid brass bow shackles for paracord bracelet Adjustable brass bow shackles

-

HF anchor shackle heavy duty forged de ring 4 pull ring d

Other Products

-

$995.00 / piece

$995.00 / piece -

$800.00 / piece

$800.00 / piece -

$800.00 / piece

$800.00 / piece -

$0.01 / piece

$0.01 / piece -

$0.01 / piece

$0.01 / piece -

$1300.00 / piece

$1300.00 / piece -

$1.85 / piece

$1.85 / piece -

$0.09 / piece

$0.09 / piece -

$800.00 / piece

$800.00 / piece -

$0.001 / piece

$0.001 / piece