Organic fertilizer granulator cow dung chicken manure sheep dung, organic fertilizer production line

-

Supplier: Henan Tongyida Heavy Industry Technology Co., Ltd. -

Region: Henan, China -

Contact: Mr Jason Zhang -

Price: $5000.00 /set -

Min. Order: 1 set

| Packaging Detail: | Standard export package for organic fertilizer pellet production line; | Granule shape: | Round Ball Shape; |

| Power (kW): | 55; | Key Selling Points: | Long Service Life; |

| Warranty: | 1 YEAR; | Machine Type: | Granulator; |

| Package Preview: | ; | Usage: | Making Organic Fertilizer Granules; |

| Applicable Industries: | Manufacturing Plant,Farms; | Local Service Location: | None; |

| Product Name: | Organic fertilizer production line; | After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Paypal; | Place of Origin: | Henan China; |

| Showroom Location: | None; | Capacity: | 1.5-2.5t/h; |

| Port: | Qingdao, China; | After Warranty Service: | Video technical support,Online support,Field maintenance and repair service; |

| Raw material: | Animal live stock/human Manure; | Output (kg/h): | 2000; |

| Certification: | ISO CE SGS,ISO/CE/SGS; | Product Type: | Fertilizer; |

| Condition: | New; | Weight (KG): | 2400; |

| Dimension(L*W*H): | 4250*1850*1300mm; | Supply Ability: | 100 Set/Sets per Month organic fertilizer production line; |

| Voltage: | 220V/380V/415V/600V; | Type: | Granulate Making Equipments; |

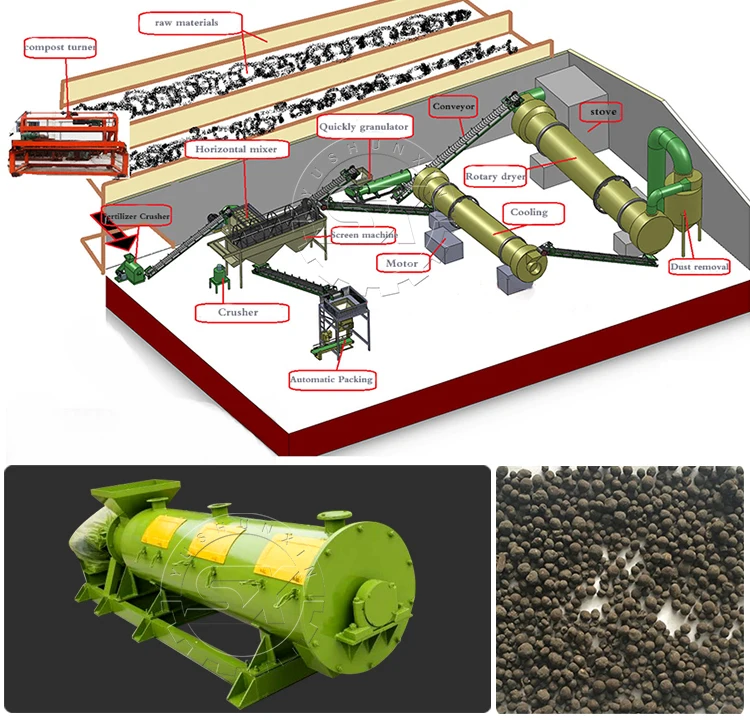

Organic fertilizer granulator cow dung chicken manure sheep dung, organic fertilizer production line

(1) The production granule is round ball

(2) The organic content can be high to 100%, make pure organic granulate.

(3) Organic material particles can grow up under a certain force, no need to add binder when granulating.

(4) Product granule is massy, it can sieve directly after granulation to reduce the energy consumption of drying.

(5) After fermentation organics don’t need to dry, moisture of the raw material can be in 20%-40%.

Working Principle of capacity 1 ton per hour organic fertilizer granulator/pelleting machine

The new type organic fertilizer granulator uses high speed rotating mechanical shearing force and the resulting air power, making continuous implementation of the fine powder material in the machine mixing, granulating, spheroidizing, density and other processes, which achieves the goal of the granulation. The granulation method makes the pellet rate higher, and the granule is more beautiful, while saving energy and improving efficiency.

Specification

Model | Installation angle | Capacity(t/h) |

Power(kw) |

Feed moisture | Feed size(mesh) | Overall size(mm) |

JZ-600 | 2°- 2.5° | 1-1.5 | 37 | 20%-40% | 50 | 4100*1600*1150 |

JZ-800 | 2°- 2.5° | 1.5-2.5 | 55 | 20%-40% | 50 | 4250*1850*1300 |

JZ-1000 | 2°- 2.5° | 2-4 | 75 | 20%-40% | 50 | 4700*2350*1600 |

JZ-1200 | 2°- 2.5° | 4-6 | 90 | 20%-40% | 50 | 4900*2550*1800 |

JZ-1500 | 2°- 2.5° | 6-8 | 110 | 20%-40% | 50 | 5500*2800*2000 |

Finished production

New type organic fertilizer granulator/Double rollers press granulator/Rotary Drum Granulator

Click for more information about different type of granulator machine

1.Small machine and spare parts packed in wooden box.

Also could packing according to customers' requests.

2. Production line or large quantity packed 20ft container/ 40ft container

The normal package is wooden box. If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

Pre-sale Service

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

4.Training periodically high qualified service technician.

5.Free CAD design: if you can provide the material, your aim capacity and your factory information, we can make a free CAD design for you.

After-sales Service

1.Highly inspecting equipments in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.Assisting our clients for foundation construction of equipments;

4.Dispatching engineers to install and debug equipments;

5.Training the first-line operators on site;

6. Regularly visit clients to solve production problems Providing life-long maintenance service

7.Providing technical exchanging.

1.Company Profile:

2.Product Range

The main products are: organic fertilizer machine, compound fertilizer machine, blending fertilizer machine, waste, sludge and other organic waste harmless treatment fertilizer equipment, organic fertilizer turning machine, organic fertilizer crusher, organic fertilizer sieving machine, mixing fertilizer batching machine,

organic fertilizer mixer, organic fertilizer granulator, organic fertilizer drying machine, organic fertilizer coating machine, granule/powder transfer packaging machine, various auxiliary machine and accessories.

3.Our customers:

4.Install

For more information, feel free to contact me.

Sophie

WhatsApp/WeChat/Imo: +86-13838134483

-

Chicken manure granulator fertilizer/twin roll extrusion granulator fertilizer for sale

-

Industrial large capacity ZL rotary dry granulator granulator mixing granulator food powder processing production line

-

Ganulator Machine Chemicals, Minerals, Inorganic Powder Granulator Fertilizer Double Roll Press Machine Customized 15kw, 30kw CN; JIA 1t

-

Cat litter bentonite granulator/dry powder granulator

-

Organic fertilizer granulator

-

Latest Design Urea Fertilizer Production Equipment

-

1000-1800 kg organic fertilizer bentonite pellet machine per hour

-

Fully automatic urea fertilizer plant/NPK fertilizer production line fertilizer machine

-

Disc Granulator Fertilizer Disc Granulator

-

High quality organic npk compound fertilizer making machine drum granulator for sale

Other Products

-

$900.00 / set

$900.00 / set -

$60000.00 / set

$60000.00 / set