Custom Helical Gear and Pinion

-

Supplier: Zhangjiagang Longsum Import And Export Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr. Barry Huang -

Price: $1.00 / >=200 pieces -

Min. Order: 200 pieces

| Port: | SHANGHAI; | Application: | Transmission Gearbox; |

| Shape: | Other; | Service: | OEM ODM; |

| Type: | Power Transmission Parts; | Module (M): | M0.5-M6; |

| Marketing Type: | Ordinary Product; | Video outgoing-inspection: | Provided; |

| Size: | Customized Accepted; | After Warranty Service: | Online support; |

| Warranty: | 3 months; | Supply Ability: | 2000.0 Piece/Pieces per Month Custom Helical Gear and Pinion; |

| Standard or Nonstandard: | Standard; | OEM Service: | Accepted; |

| Product Name: | Custom Helical Gear and Pinion; | Showroom Location: | None; |

| Brand Name: | LS; | Place of Origin: | Jiangsu China; |

| Package Preview: | ; | Core Components: | Gear; |

| Machinery Test Report: | Not Available; | Material: | 45C, 40Cr, 20CrMnTi, 20CrMo, 42CrMo, etc.; |

| Tolerance: | 0.01-0.05mm; | Heat Treatment: | Case Hardening; |

| Applicable Industries: | Manufacturing Plant; | Pressure Angle: | 20 Degree; |

| Processing: | Hobbing; | Payment Terms: | L/C,T/T; |

| Condition: | New; | Tooth Profile: | Helical Gear; |

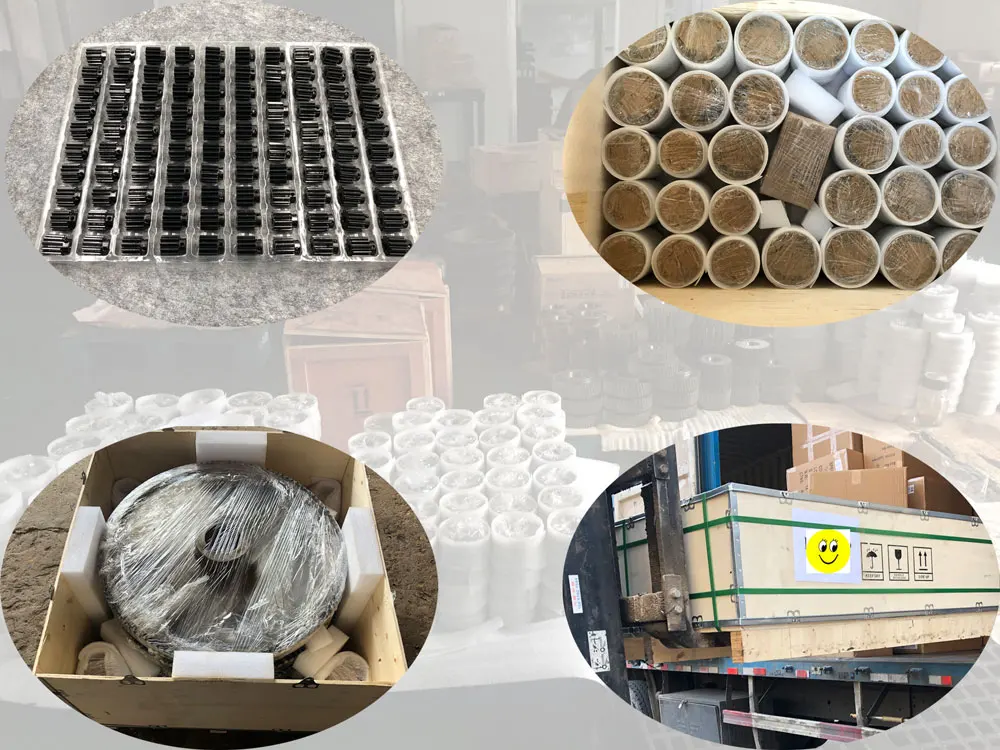

| Quality: | Tolerance; | Packaging Detail: | Custom Helical Gear and Pinion Seaworthy Plywood Packaged; |

| Warranty of core components: | 3 months; | Local Service Location: | None; |

Custom Helical Gear and Pinion

Helical gears are considered a specialty family of engineered component. This type of product includes precision teeth that are produced with a very tight angle tolerance. What's special about these teeth? The unique teeth slowly engage the operation; resulting in an extremely smooth and silent operational noise. The teeth are longer and stronger than other gears; resulting in a greater carry weight load. This value explains why this type of specialty OEM part is being selected for many electrical and hybrid energy applications, rather than other traditional styles of gearing families. Helical gears are normally utilized for mating two parallel shafts or in crossed mesh applications to connect a pair of perpendicular shafts.

| Gear Types |

spur gear, helical gear, internal spur gear, ring gear, straight/spiral bevel gear, hypoid gear, crown wheel & pinion, gear shaft, worm gear & worm shaft, spline shaft & bushing, etc. |

| Gear Material |

Steel: C45, 40Cr Aluminum Alloy: 2024, 7075, etc. Brass, Bronze, Aluminum Bronze, etc. POM Plastic, MC901 Nylon, etc. |

| Processing |

blank turning tooth hobbing, broaching, milling, shaping, etc. bore honing tooth shaving, tooth grinding |

| Heat Treating |

tooth induction quenching, vacuum quenching, etc. for 45-50HRC; carburizing for 56-62 HRC; nitriding, carbon-nitriding for gears required abrision resistant; |

| Application | Automotive, Agricultural, Electronic, Industrial, Medical, Defense, Off-highway, ect. |

All gears are packaged for safe shipping and convenient storage. Gears are carefully packaged using the most appropriate materials and method for the gear type.

We'd like to work with your forwarder to ship the products to you. We also work with experienced forwarders to shipping the products to client all over the world. If you don't have any forwarder to do the shipping, please let us know the most convenient port for you, then we can arrange the shipment for you.

Longsum Company has continued to build a solid reputation for quality, service and reliability. From the very beginning, Longsum has provided high precision spur, helical and bevel gears that meet the rapidly changing and demanding requirements of the gear industry.

Longsum's primary goal is to ensure customer satisfaction by improving the manufacturing process, eliminating waste, and delivering a quality product on time at a competitive price.

To achieve those objectives, Longsum has embraced the continuous improvement philosophy while implementing the most advanced technology available for the machining, heat treatment and inspection of our products. We are an verified supplier on Alibaba and have consistently received vendor awards for both quality and on-time delivery. Longsum takes great pride in its history of steady growth and its record for maintaining long-lasting customer relations.

Q: Do you make customized products based on our design/drawings?

A: YES, we are a professional supplier of gear & shaft components, gear rack & pinion, our experienced engineering team will evaluate the drawings and advise the suitable fabricating process.

Q: Whether some samples can be provided?

A: YES, We are happy to make samples for testing on prototype device, and assure the quality standard, We'll charge sampling freight, it'll be refunded while the mass production accummulate to a certain amount.

Q: What is the MOQ?

A: Based on the drawings, trial orders will be accepted.

Q: How to deal with the parts received when they are found to be in poor quality?

A: We have equipments for dimensional inspection, gear measurement center to inspect the tooth accuracy. The parts will be inspected by hand and certain equipmrnts. If there got flaws on the shipments from us, we'll send new parts or offer discount in the following orders. BESIDES, we suggest to start the Order via Trade Assurance for buyer's benifit.

-

Hot Sale Discount Multi-Blade Caster Wheels Pvc Nylo Plastic

-

SHS Steel Booster High Torque Gear Set 13:1 16:1 18:1 100:200 100:300 For Ver2/3 AEG Gearbox

-

Good Quality CNC Brass Small Bevel Gears OEM Gear Factory in China

-

Factory supply steel spur gears according to drawings

-

chihai motor Hareded Metal 18:1 cylindrical gear set For JM Gen.8/JM Gen.9 M4A1/LH Vector Gen.2/XWE M4 upgrade

-

OEM precision small nylon plastic toy gear

-

chihai motor 14 tooth blue piston full steel reinforced nylon fiber for tactical hunting gear Aeg

-

MTZ 1221 tractor accessories three gear assembly 1521-2308030

-

Blaster motor chihai hardened metal gear set for JM Gen.8 M-4A1/JM Gen.9 M4A1/LH Vector Gen.2/XWE M4

-

SRC series helical gear reducer for motor reducer

Other Products

-

$2.00 / piece

$2.00 / piece -

$5.00 / piece

$5.00 / piece -

$5.00 / piece

$5.00 / piece