Mini Small vacuum Former forming machine for plastic acrylic PVC PE PET ABS sheet Signage making

-

Supplier: Shandong Yuantong Century Intelligent Technology Co., Ltd. -

Region: Shandong, China -

Contact: Ms Daisy Zhang -

Price: $3100.00 /set -

Min. Order: 1 set

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Alipay; | Forming area(mm): | 540*540mm; |

| Consumable: | heating tube; | Voltage: | 380V or 220V; |

| Core Components: | Engine,Motor,Pump; | Control: | Button or PLC control; |

| Warranty: | 1 year; | Supply Ability: | 200 Set/Sets per Month; |

| Place of Origin: | Shandong China; | Package Preview: | ; |

| Air Comsumption(L/min): | 0.01; | Dimension(L*W*H): | 930*950*1300mm; |

| Air Pressure(MPa): | 0.08; | Open method: | automatic; |

| Key Selling Points: | Long Service Life; | Type: | acrylic thermoforming machine; |

| Weight: | 230kg; | Forming Length (mm): | 600; |

| Processing Type: | Plastic Thermoforming Machine,Plastic Thermoforming Machine; | Marketing Type: | Hot Product 2019; |

| Weight (T): | 0.23; | Plastic Type: | PMMA,PVC,PS,PA,PP,EPS,PET; |

| Max.Forming Height(mm): | 200; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Showroom Location: | Egypt,Turkey,United Kingdom,Italy,France,Philippines,Peru,Indonesia,Pakistan,India,Thailand,Morocco,Kenya,Chile,UAE,Algeria,Malaysia,Australia; | Brand Name: | Baoyuantong; |

| Heating Power (kW): | 3; | Working area: | 600*600mm; |

| Packaging Detail: | Standard export package which can protect the machine well for outdoor advertising equipment; | Certification: | ce,SGS; |

| Forming Width (mm): | 600; | Power(KW): | 11; |

| Applicable material: | Acrylic,PS, PVC,ABS etc; | Local Service Location: | Egypt,Turkey,United Kingdom,Italy,France,Germany,Philippines,Indonesia,India,Australia,Morocco,UAE; |

| Product Type: | Other; | Water Comsumption(L/min): | 0.02; |

| Warranty of core components: | 1 Year; | Port: | Qingdao Port ,Ningbo Port ,Shanghai Port ,Tianjin Port ,Guangzhou Port .......; |

| Condition: | New; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Video outgoing-inspection: | Provided; | Max.suction forming depth: | 200mm; |

| Machinery Test Report: | Provided; |

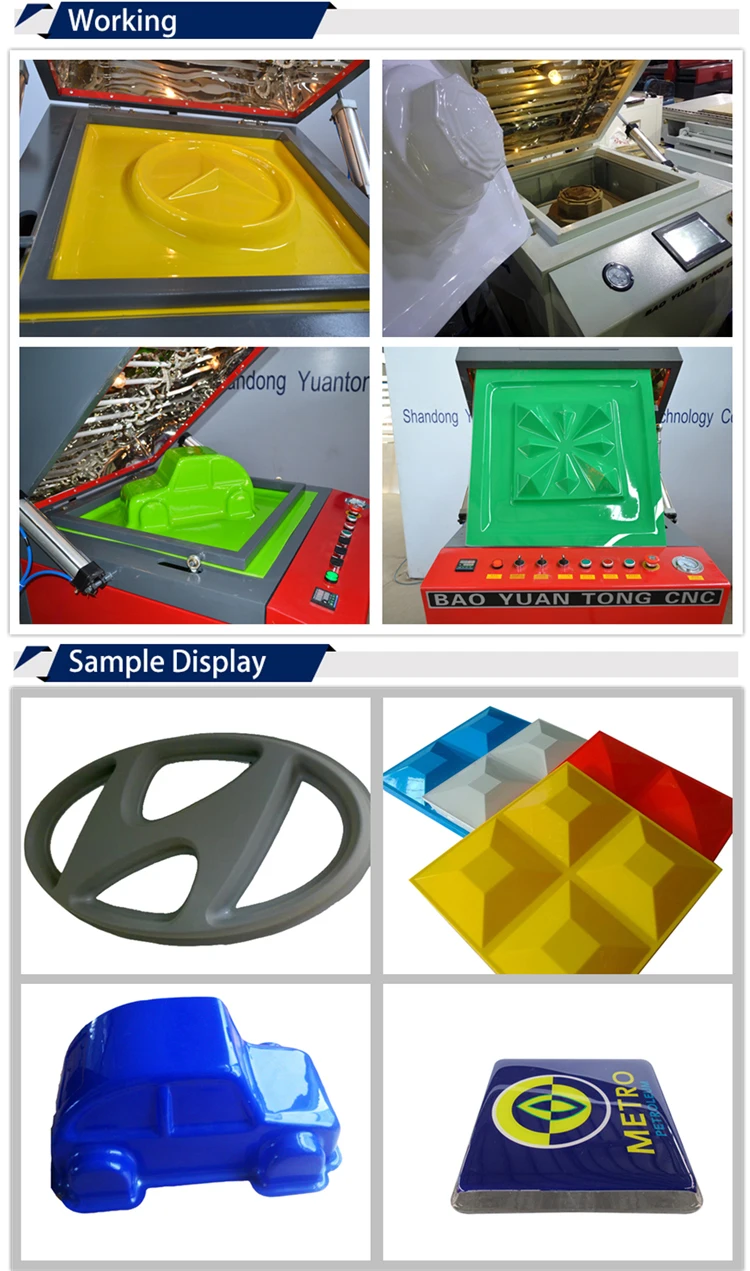

low price abs acrylic plastic automatic mini thermoforming vacuum thermo forming machine

Application Industry and material :

1)Plastic moulding&mask making

2)Advertising signage making

3)University or research institutions teaching experiments

4)Chocolate and cake package box making

5)Industrial & automobile decoration

6)Other thermoplastic material forming industrial

7) Application material: PMMA(Acrylic ), PVC,ABS,PE,PET ,Poly styrene ,poly propylene ect.

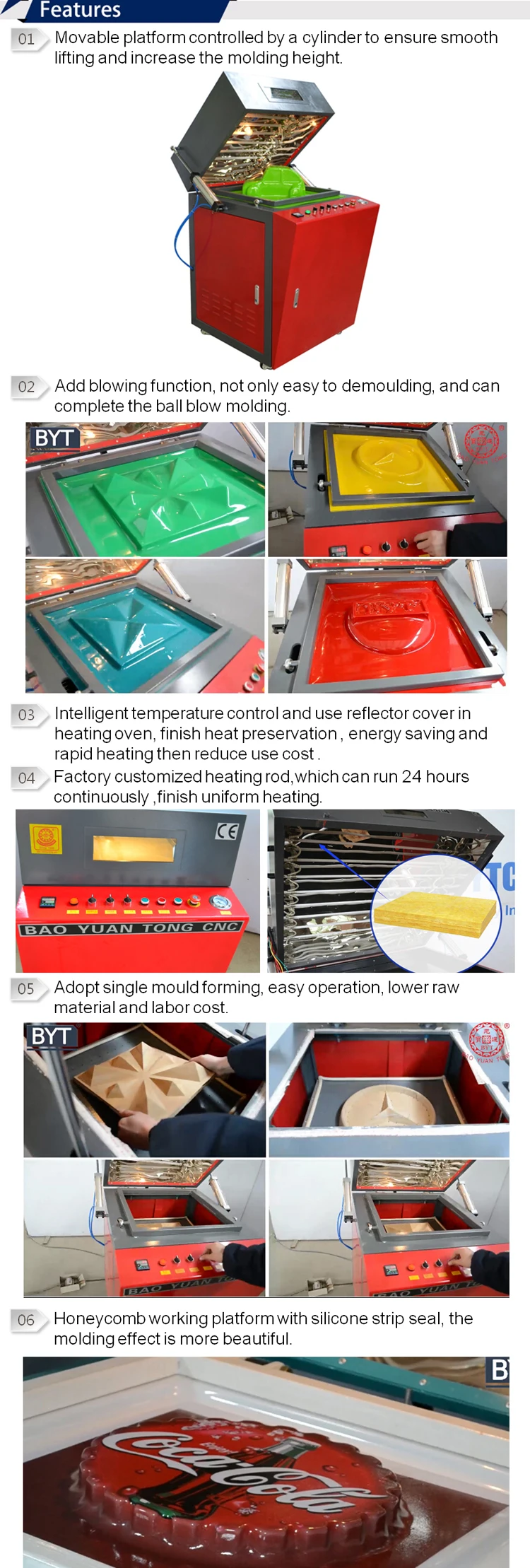

Features:

1. Movable platform controlled by a cylinder to ensure smooth lifting and increase the molding height.

2. Add blowing function, not only easy to demoulding, and can complete the ball blow molding.

3. Intelligent temperature control and use reflector cover in heating oven, finish heat preservation , energy saving and rapid heating then reduce use cost .

4. Factory customized heating rod,which can run 24 hours continuously ,finish uniform heating.

5. Adopt single mould forming, easy operation, lower raw material and labor cost.

6. Honeycomb working platform with silicone strip seal, the molding effect is more beautiful.

Technical data:

|

Model |

BSX-600 |

|

Working area(mm) |

540mm*540mm |

|

Total power(kw) |

3.6kw |

|

Max formed depth |

200mm |

|

Voltage(V) |

380V or 220V |

|

Vacuum pump output |

20m3/h |

|

Net weight |

220kg |

|

Machine size |

930mmx950mmx1300mm |

Mini Small vacuum Former forming machine for plastic acrylic PVC PE PET ABS sheet Signage making

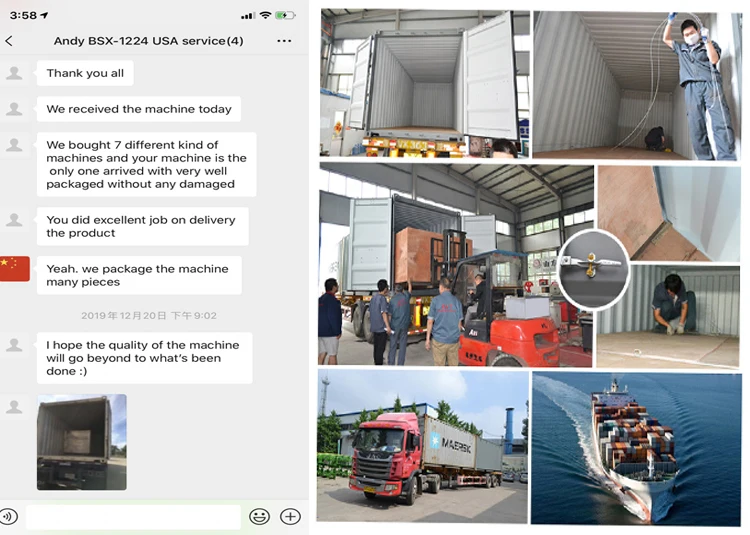

1.After the completion of machinery production, the factory inspectors shall check and put the equipment into storage.Before the delivery of the equipment, the after-sales engineer shall conduct secondary inspection and ensure the quality of the machine meets the customer's requirements

2.Clean the whole machinery , protect the parts that need oil, and check the related parts again .

3. Anti-collision package edge: All parts of the machine are covered with some soft materials.

Whole film packaging machine: Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust.

4. Fumigation wooden box:Our wooden box is fumigated, do not need to check the wood, saving the transport time and money.

Our responsibility -- provide stable and reliable performance of the equipment and provide high-quality service, let every user satisfaction. (Click the picture ,listen user's voice)

Company Information

Company Information

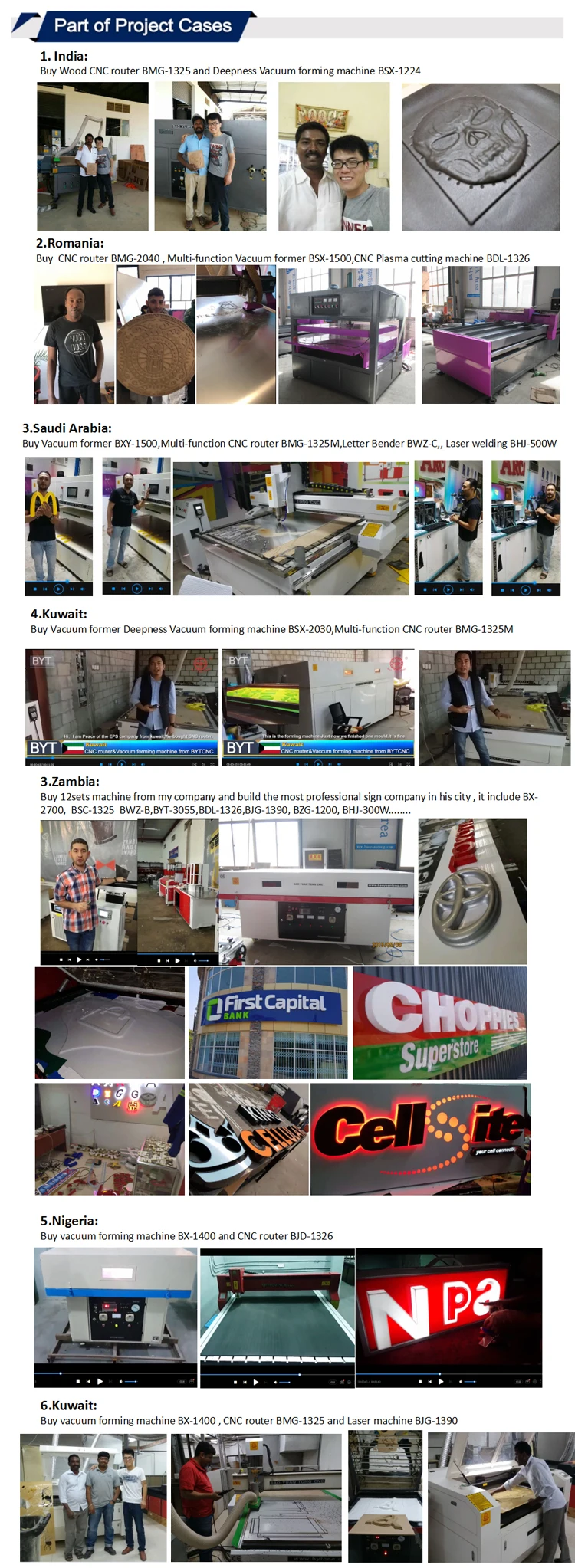

SHANDONG YUANTONG CENTURY INTELLIGENT TECHNOLOGY CO.,LTD This factory build in 1996, mainly producer vacuum forming machine ,vacuum press ,CNC router ,laser machine and channel letter bending machine ,the products export to more than 152 countries and get CE and SGS certification , service more than 2000 customers

Woodworking CNC router , Vacuum Membrane Press,Advertising CNC router ,Vacuum Forming machine ,Laser Machine ,Channel Letter Bending Machine ,Multi-fuction CNC router ,Laser welding machine ..

Mini Small vacuum Former forming machine for plastic acrylic PVC PE PET ABS sheet Signage making

Mini Small vacuum Former forming machine for plastic acrylic PVC PE PET ABS sheet Signage making

Q1:Which material can use ?How to choose vacuum forming machine ?

A1:Vacuum forming machine can use PMMA(Acrylic ), PVC,ABS,PE,PET thermoplastic material .

About how to choose vacuum former ,usually we need to know below questions:

1) The material type and material thickness ,Less than 6mm

2) Finish forming products size

3) Sample pictures

Q2:For this machine what is the working voltage,if you accept the customized volage ?

A2:The BSX-600 and BX-1400 working voltage 220V 50HZ 1P ,Other type normally working voltage is 380V/50HZ/3P, we can accept customized voltage,for example: 220V/60HZ/3P ,415V/60HZ/3P ect.

Q3:When this machine working ,if it need any accessory equipment ?

A3:If choose the heating box is moving by air cylinder ,when the machine working it need compressor air . For this machine working if you use MDF mould and want to make by yourself ,so you need prepare wood CNC router ; When finish forming need trim off unwanted edge , need trimmer . for this machines we all can provide

Q4:For the working area or forming height if you can accept customized ?

A4:Yes ,we can accept the customized working area and forming height , now we finish the BSX-2030 max forming height 450mm .

Q5:After I buy this machine how you arrange training ?

1) When delivery the machine with operation manual and video ,meantime all the files be saved in U disc ,send to you together .

2) After the machine delivery ,our sales-service engineer will contact with you and inform you ,when receive the machine contact with him ,he will service for you.

3) When you use this machine , any questions you can contact with our after-sales service ,they provide 24Hours/7Days online service

|

|

|

| BSX Deepness vacuum former | BXY Vacuum press forming machine | Solid surface membrane press |

-

2024 new plastic cup making machine price of plastic cup making machine

-

Plastic PP Container Vacuum Forming Machine Thermoforming Machine Plastic Sheet German Vacuum Pump (100m3/h) Popular Products 2023 100

-

Fully automatic takeout disposable food container PS foam Thermocol lunch box machine foam tableware production line

-

PS Disposable Food Container Thermocol Platesetter

-

High speed plastic bottle cap molding machine

-

Used Small High Speed Automatic Plastic Cap Thermoforming Machine Cylindrical Cap Vacuum Forming Machine

-

Machine Melamine Cutlery Set Cutlery Machine blow molding

-

Hot Sale Old Thermoforming Machine Food Container Disposable Plastic Tray/Cup

-

Disposable Cup Automatic Plastic Cup Thermoforming Machine

-

Disposable Plastic Glass Machine

Other Products

-

$3300.00 / set

$3300.00 / set -

$6300.00 / set

$6300.00 / set -

$3400.00 / set

$3400.00 / set -

$5630.00 / set

$5630.00 / set -

$5000.00 / set

$5000.00 / set