Tyre Retreading Machine Production line

-

Supplier: Shandong Mingo Industrial Equipment Co., Ltd. -

Region: Shandong, China -

Price: $30000.00 /set -

Min. Order: 1 set

| Voltage: | 380V/220V,for your optional; | Brand Name: | Mingo; |

| Weight (KG): | 4400 KG; | Packaging Detail: | under costomer`s requirement; |

| Supply Ability: | 10 Set/Sets per Month; | Showroom Location: | None; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram; | Place of Origin: | Shandong China; |

| Control manners: | Automatic control; | Medium: | Hot-air; |

| After Warranty Service: | Video technical support,Online support; | Material: | Carbon Steel Q345R; |

| Package Preview: | ; | Local Service Location: | None; |

| Work temperature: | 150~200℃ curing temperature; | Customized: | All dimentions, temperatures, pressures, colors can be customized; |

| Key Selling Points: | Energy saving; | Warranty: | 1 Year; |

| Applicable Industries: | Manufacturing Plant,Machinery Repair Shops; | Design pressure: | 1.5Mpa; |

| Power (kW): | 88; | After-sales Service Provided: | Field installation, commissioning and training; |

| Condition: | New; | Dimension(L*W*H): | 4000MM*2200MM*2200MM; |

| Design temperature: | 200℃; | Function: | Old tire retreading; |

| Port: | Qingdao; | Name: | Tyre Retreading Machine Production line; |

Tyre Retreading Machine Production line

Rubber vulcanization is a chemical process at a given pressure, temperature and time for converting natural rubber into more durable materials by the addition of sulfur. These additives modify the polymer by forming cross-links (bridges) between individual polymer chains. Vulcanized materials are less sticky and have superior mechanical properties. And vulcanization autoclave is used widely for this chemical process.

tyre clean firstly dry tyre → inspecting tyre → buffing tyre → buffing outer wound of tyre → buffing inner wound of tyre → secondly inspecting tyre → repair inner wound → brushing adhesive on roof of tyre → secondly drying tyre → repair outer wound → affix middle rubber piece → tread building →assemble envelop → assemble inner tyre → assemble curing rim → inspecting inner tyre and curing rim → curing→ disassemble curing rim→ disassemble inner tyre → disassemble envelop → inspect end product → embellish tyre→ store tyre.

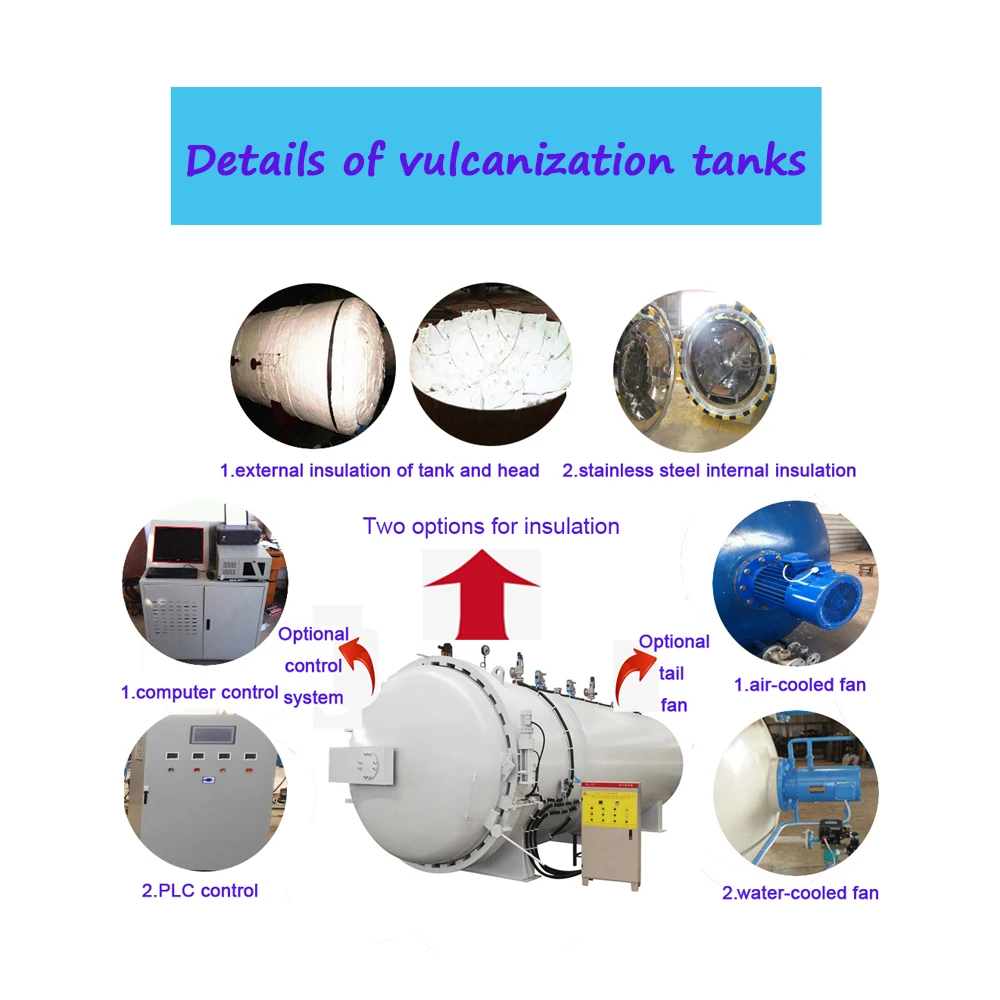

Heating mode:

1.Heat conduction oil heating

2.Steam direct heating

3.Electrically heated air

4.Electrically heated steam

Door opening mode:

1.Power-driven

2.Hand-driven

3.Hydrodynamic-driven

4.Various types of vulcanization tank and quick-opening door safety interlocking devices can be provided separately.(Company advantage)

Sealing mode:

Inflatable silicone seal rings are used for tank door flanges which is simple and convenient to maintain and the sealing effect is obviously better than other methods with more than 2 years of service life.

Safety chain mode:

1.Pressure automatic safety interlock

2.Manual safety chain

Temperature control mode:

It uses double layer external insulation, saving thirty percent of energy consumption than ordinary insulation.

Pressure control mode:

(1) Pressure in vulcanization tank is automatically controlled by pneumatic corner valve.

(2) Set up manual valve for easy manual control.

(3) Set up another set of disc pressure gauge.

(4) The tank body is designed with two flanged open safety valves, which can be opened automatically after the designed pressure is reached.

Time control mode:

After setting working procedure, heating/keep-heating time and vulcanization time all will be automatically controlled.

Loading mode:

Two rails in tank, using national standard guide rail.

Production flow:

Brand and Material of Major Components

No. | item | material |

1 | dished head | carbon steel Q345R |

2 | tank | carbon steel Q345R |

3 | flange | forged carbon steel |

4 | safety interlocking device (pressure automatic) |

|

5 | track | carbon or stainless steel |

6 | manual door opening device |

|

7 | saddle | carbon steel Q235B |

8 | High temperature and high pressure fan ventilator | air or water cooling |

9 | thermal insulation head | carbon steel Q235B |

10 | Insulation material (double layer) | aluminum silicate cotton |

Q: Are you manufacturer or trading company?

A: We are a professional manufacturer.

Q: Do you have full set of used tyre retreading machine?

A: Yes,we do.

Q: If we plan to visit your factory, can we see the machinery for retreading tires?

A: Yes, we can take you to visit our other customers, there is a complete tire retreading line.

Q: What if there is something wrong with the machine within one year?

A: We have two ways to solve the problem.

a. Phone call/on-line service to solve the problem.

b. We will take video to show ’how to solve the problem’. All the problems can be solved by video guidance.

Q: How about the installation? And what if the machine goes down?

A: We will do that. There are two options.

a. We could appoint our engineer to your company to install and debug, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side.

b. On-line service will be provided. If still is under guarantee period, the necessary accessories and parts will be provided free, but the transportation cost of it shall be on your side.

-

Low-price car tire retreading equipment/car tire retreading complete production line

-

Used tire retreading machine/tire retreading machine made in China

-

High quality rubber High quality rubber refill materials

-

Used Tire Retreading Machines Retreading Vehicles Renew Equipment at Low Prices

-

Refurbished machine

-

REENCAUCHADORA LLANTAS Tire Retreading Machine

-

Tire Vulcanizer Repair Electric Retreading Machine

-

Automatic Electric Heating Tyre Repair Machine Hot Tyre Retreading Vulcanizing Machine Customized 220V/380V 1500 KG CN;SHN Q345R

-

Tire Recapping Machines for tyre retreading process

-

Rubber Extruder Gun for Tire retreading machine handheld

Other Products

-

$68000.00 / set

$68000.00 / set -

$3000.00 / set

$3000.00 / set -

$88000.00 / set

$88000.00 / set