High efficient wood charcoal production line sawdust briquette production line

-

Supplier: Zhengzhou Shuliy Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Beco Yang -

Price: $5000.00 /set -

Min. Order: 1 set

| Keyword: | Charcoal Coal Briquetting Machine; | Supply Ability: | 100 Set/Sets per Month; |

| Type: | Briquette Machines; | Usage: | Coal Briquette Shaping Machine; |

| Application: | Barbecue (BBQ); | Warranty: | 1 year; |

| After-sales Service Provided: | Video technical support,Engineers available to service machinery overseas; | Motor Type: | AC Motor; |

| Raw material: | Biomass; | Port: | Qingdao; |

| Quality: | High Reputation; | Installation: | Engineers Guiding; |

| Certification: | CE ISO; | Condition: | New; |

| Place of Origin: | Henan China; | Payment Terms: | L/C,T/T,Western Union,MoneyGram; |

| Name: | Charcoal Briquette production line; | Brand Name: | shuliy; |

| Function: | Energy Saving; | Material: | Steel; |

| Packaging Detail: | wooden case; |

If it is the new business for you , you can choose the whole line , from the material to the final product.

raw material:

To make lump charcoal or charcoal powder from biomas materials (wood, wood branch, leaves, coconut shell, coconut dust, bamboo, palm thread, palm kernel, sugarcane bagasse, rice husk, cotton stalk, jute stick, or other agricultural wastes)

The raw materials could be any waste from agriculture or forestry. Such as: wheat straw, sunflower husk, coffee husk, soybean husk, rice husk, wood chips, sawdust, tae waste, cotton stalk, paddy straw, peanut husk, and any other type of agro-forestry waste.

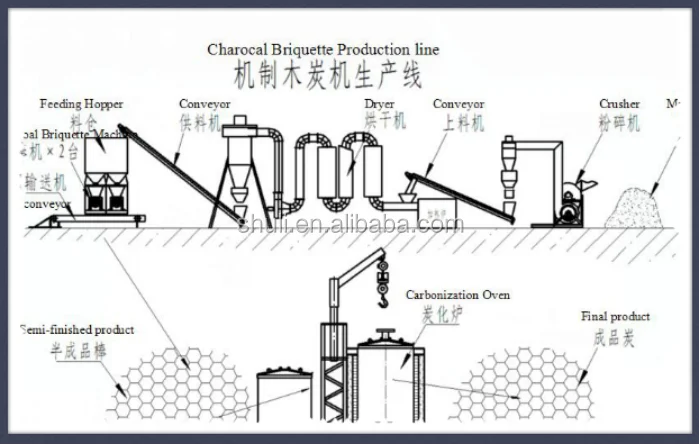

Flow chart:

Raw material (biomass) → Wood sawdust crusher machine → dryer → sawdust briquette machine → Charcoal furnace → Charcoal briquettes

Working process:

Steps 1: Crusher:

The raw materials are shredded into evenly shaped sawdust, typically 3 to 5 mm in size.

Steps 2: Sawdust Dryer:

Sawdust humidity conditions are required to be between 8% and 10%, which requires a dryer to reduce humidity.

Step 3: Sawdust Charcoal Briquette machine:

This is a rod forming machine. The material is made into a wooden rod by high pressure molding at a high temperature of 300 to 350 degrees.

Step 4: Carbonization furnace:

After the sawdust briquette is formed, the shape is uniform and the humidity is right, so that it can be directly carbonized.

Flow chart:

The final product:

♥. Pre-sale-service

Design and manufacture machines for you as your special requirement, provide you with project, process design and pruchase program.

♥. On-sale-service

Accompany with you to look around our factory, explain the manufacture process of our machines and check the working performance of our machine.

♥. After-sale-service

Engineers are available to install debugging equipments of the whole production line, besides, commissioning and training operators on site.

-

Factory price small Y83-160/250/315/400/500 scrap copper hydraulic chip briquetting machine

-

New Product BBQ Compressed Charcoal Honeycomb Forming Machine

-

650 barbecue charcoal power cake press machine agricultural briquette forming machine acasia wood coal machine brikett manufactory

-

Energy-saving hydraulic briquette forming machine forming small briquette forming machine charcoal forming machine

-

Coal Processing Machine Barbecue Brick Briquette Making Machine

-

China Famous Products Coal Powder Briquetting Machine Coal Slime Briquetting Machine Raw Coal Briquetting Machine

-

Small Charcoal Briquette Manufacturer Honeycomb Briquette Machine South Africa

-

Coal Comb Factory Coal Briquette Making Machine Price

-

Discount large capacity sawdust charcoal forming machine coconut shell charcoal forming machine

-

Excellent Bio Coconut Shell Compressed Coal Maker Charcoal Briquettes Machine

Other Products

-

$7500.00 / set

$7500.00 / set -

$800.00 / set

$800.00 / set -

$22000.00 / set

$22000.00 / set -

$850.00 / set

$850.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 / unit

$1000.00 / unit -

$7000.00 / unit

$7000.00 / unit -

$1000.00 / set

$1000.00 / set -

$100.00 / piece

$100.00 / piece