Passenger Material Hoist

-

Supplier: Beijing Ihurmo Industry Co., Ltd. -

Region: Beijing, China -

Contact: Mr Ares Liu -

Price: $19800.00 /set -

Min. Order: 1 set

| Color: | Red and other; | Warranty of core components: | 1 Year; |

| Packaging Detail: | wooden box; | UNIQUE SELLING POINT: | Low noise cab; |

| Condition: | New; | Loder Weight: | 2000kg; |

| Core Components: | Gearbox,Motor; | Marketing Type: | New Product 2020; |

| After Warranty Service: | Video technical support,Spare parts; | Payment Terms: | L/C,T/T,Western Union,MoneyGram; |

| Dimension(L*W*H): | 3m*1.5*2.5; | After-sales Service Provided: | Engineers available to service machinery overseas,Video technical support,Online support,Free spare parts; |

| Showroom Location: | Russia,UAE; | Brand Name: | IHURMO; |

| Local Service Location: | Russia,UAE; | Machinery Test Report: | Provided; |

| Package Preview: | ; | Video outgoing-inspection: | Provided; |

| Rated Loading Capacity(kg): | 2000kg; | Max Lifting Height: | 400m; |

| Applicable Industries: | Construction works ; | Hoisting Speed: | 36m/min; |

| Place of Origin: | Beijing China; | Warranty: | 1 Year; |

| Port: | TIANJIN,QINGDAO; | Supply Ability: | 5000 Set/Sets per Year; |

|

Passenger Material Hoist Technical Parameters |

|||||

|

CATEGORY |

NAME |

Parameters |

NOTE |

||

|

Cage |

Cage |

3×1.3×2.5m 3×1.5×2.5m |

Sand blasting, Powder painting steel board with punching. Cage bottom: 4mm thickened plate. |

||

|

Cabin |

Seat, tool case, control paned |

Plastic powder spraying |

|||

|

Door |

Perforated plate |

Plastic powder spraying |

|||

|

Gear |

Tooth profile, module, material. |

The gear is tested by professional equipment. |

|||

|

Fence |

Fence of construction hoist |

Perforated plate (Plastic powder spraying) |

The price of plastic-spraying perforated plate is twice that of the expanded plate mesh. |

||

|

Driving device |

Motor |

Type:YZZ132M-4 Power:11kw Electric current:24A Torque:120Nm Rotating speed: 1390r/min Protection level: IP55 Insulation Class: F Voltage:380v/50hz |

1. The housing of the motor of our construction lifting equipment is made of 104# aluminum conforming to the national standard thus is not easy to crack. 2. The worm gear of our construction hoist is made of 94# tin bronze and other parts are made of 38 # chrome bronze. 3. All these parts, except the bronze worm gear, are processed with heat treatment, blackening and nitriding. 4. Service life of the motor can be 10-15 years. |

||

|

Reducer gear box |

1:16 speed ratio |

|

|||

|

Mounting plate |

High mounting precision |

It works smoothly and steadily. |

|||

|

Scaling ladder |

Additional equipment installed on the driving system |

Features: The scaling ladder makes the mounting of the construction hoist more convenient, flexible, and humanistic. |

|||

|

Mast section |

Mast section |

Q235 #20 seamless steel pipe Surface |

treatment: Paint spraying (standard configuration), hot-dip galvanizing (optional configuration) |

||

|

Bolt |

8.8 Grade M24 |

High strength |

|||

|

Rack |

Rack |

55# tyre steel |

Service life of the rack of our passenger hoist: about 10 years |

||

|

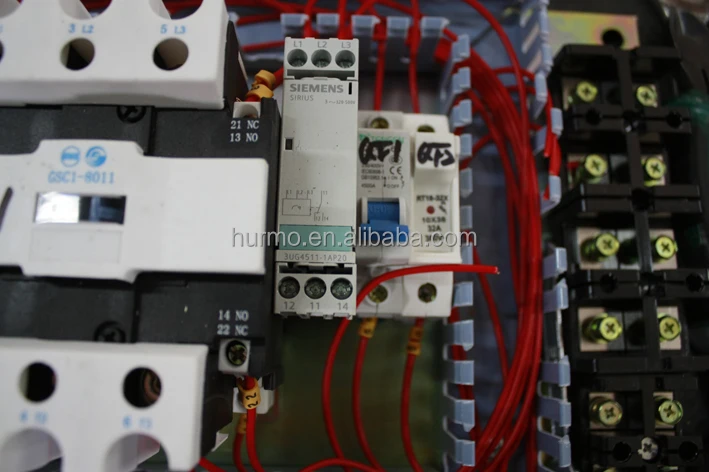

Electrical system |

Electrical system |

Main parts of the electrical parts are Siemens or Schneider products. |

a. The equipped fan has improved the heat dissipation performance of our construction hoist. b. The time delay relay makes our construction elevator work more smoothly and stably. c. The alarm bell rings when the fall arrest device stats to work. d. The failure warning light will shine when there is something wrong with the motor or the electrical system. |

||

|

Safety device |

Fall arrest device |

|

This device can control the lowering of the cage at a safe speed to prevent the cage from falling accidentally. |

||

|

Load capacity limiter |

|

1. The overload alarm buzzer will sound and the indicating light will blink when the load capacity is over high. 2. This device is intelligent controlled and is easy to operate. 3. It will display the load of the construction hoist in real time. |

|||

|

Limit switch |

|

|

|||

|

Upper limit protection device |

Prevent the Cage from dashing the mast top. |

||||

|

Lower limit protection device |

Prevent the Cage from crashing to the bottom. |

||||

|

Door limit protection device |

|||||

|

Escaping-window limit protection device |

|||||

|

Caution warning device |

Bell ringing |

||||

|

Emergency stop protection device |

|||||

|

Buffering protection device |

Springs |

||||

|

Overload protection device for motor |

This device will protect the electric motor when it runs abnormally |

||||

|

Transformer short-circuit protection device |

|||||

|

Phase sequence protection device |

Default phase and open-phase protection |

||||

|

Cable device |

1.Cable:(3×20²+2×6²) 2.Cable bucket: Standard configuration 3. Cable trolley: Optional configuration |

||||

|

Tools |

Mast section wrench |

34-36 |

2 |

||

|

Motor adjusting wrench |

M17 |

1 |

|||

|

Rack wrench |

M12 |

1 |

|||

|

Limit switch wrench |

M14 |

1 |

|||

|

Fall arrest device wrench |

1 |

||||

|

Pinion wrench |

|

1 |

|||

|

Guide roller wrench |

|

1 |

|||

|

Optional |

Frequency conversion system |

CAN200 |

1. It can achieve floor selection. 2. The frequency conversion system allows the construction hoist to stop at the designated floor precisely. 3. This system helps protect the pinion and rack. 4. The speed can be set from low to high. 5. This system allows the builder hoist to start and stop at a constant speed with low noise. 6. Smooth transmission system guarantees high stability of the whole construction elevator. |

||

IHURMO, an engineering machinery supplier in China, provides not only quality construction equipment but also first-class services.

Pre-sales Services

1.We offer customers free catalogs of our products and other relevant files.

2. We also provide free shuttle as well as board and lodging (four-star hotel) for customers who come to visit our company.

After-sales Services

1.The construction equipment we offer enjoys one-year guarantee period..

2. We supply free quick-wear parts.

3. Double hot lines for 24-hour after-sales services.

4. Online after-sales service is available as well.

5. The technical documents will be attached with the equipment while leaving the factory.

6. If needed, we will send one technician to the site to provide guidance on installation and debugging as well as the training of operators.

7.We can provide on-site service in some countries and areas where we have overseas office or agents.

In addition, OEM service is available.

Please contact us if you want to know more about us.

We are dedicated to the development and production of tower crane, construction hoist, material hoist, simple material hoist, suspended platform and all relative accessories. Our company employs 800 skillful personnel and is equipped with Panasonic professional robotic welding equipment, machining centers, large CNC gantry milling, CNC double-sided milling, CNC plasma cutting machines, computer-aided assembly line, fully automated spraying line and so on. Therefore, we can easily meet your requirements.

-

Three-wheel vehicle-mounted scissor lift platform

-

New Electric Lift Remote Control Fully Automatic Scaffolding Folding Movable Lift Interior and Exterior Decoration

-

JCPT0807HA Dingli 7.8M aerial work platform adjustable mobile scissor lift

-

Passenger Hoist Cable Anti Roller Guide Roller Door Roller Nylon Wheel For Construction Hoist Spare Parts

-

Conforms to the national standard Efficient Operation Material Elevator Passenger Use Construction Elevator

-

zlp800 rope suspended platform gondola construction

-

China factory automatic lift battery lift aerial work platform

-

Honda Engine Construction Lift

-

Construction Passenger Hoist Brake Disc Assembly

-

Electric Construction Rope Climber Lifting Tool Smart Spider Riser

Other Products

-

$400.00 / set

$400.00 / set -

$1600.00 / set

$1600.00 / set -

$1200.00 / set

$1200.00 / set -

$20000.00 / set

$20000.00 / set -

$18800.00 / set

$18800.00 / set