Small Laboratory Vacuum Dryer Oven

-

Supplier: Zhengzhou Keda Machinery And Instrument Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Alice Lee -

Price: $443.00 /set -

Min. Order: 1 set

| Material: | Stainless steel; | Voltage: | 220V/50HZ; |

| Temperature range: | RT~200 ℃; | Condition: | New; |

| Port: | Shanghai, Tianjin or China main ports; | Brand Name: | ZZKD; |

| Type: | Vacuum Drying Equipment; | After-sales Service Provided: | Online support; |

| Temperature fluctuation: | ±1 ℃; | Dimension(L*W*H): | 200*200*200 mm; |

| Packaging Detail: | Wooden case or as customer's requirments.(Small Laboratory Vacuum Dryer Oven); | Model: | DZF-6020; |

| Application: | Vacuum drying oven; | Power: | Less than 500 w; |

| Core Components: | PLC; | Certification: | CE ISO; |

| Showroom Location: | India; | Local Service Location: | United States,India; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Paypal, Escrow, Secure Payment, Credit Card; | After Warranty Service: | Spare parts; |

| Capacity: | 25 L; | Drying Capacity (kg): | 20kg; |

| Warranty: | 1 Year; | Product name: | Small Laboratory Vacuum Dryer Oven; |

| Supply Ability: | 300 Set/Sets per Month Vacuum Dryer Oven; | Warranty of core components: | 1 Year; |

| Machinery Test Report: | Provided; | Video outgoing-inspection: | Provided; |

| Installation: | Engineer Guide; | Weight (KG): | 60; |

| Vacuum degree: | 133 Mpa; | Place of Origin: | Henan China; |

| Key Selling Points: | High Safety Level; | Door seal: | Silastic; |

| Marketing Type: | Ordinary Product; | Applicable Industries: | Manufacturing Plant; |

Small Laboratory Vacuum Dryer Oven

Brief Introduction:

Vacuum Drying Oven has a chamber volume of between 8 and 430 liters and a temperature range starting at between +10°C above room temperature up to +250°C. The drying oven interiors are made of corrosion-free stainless steel 304. Underpressure accelerates drying in the vacuum drying oven. A heat-sensitive material can, therefore, be dried in the vacuum drying oven at low temperatures, and at the same time, the vacuum drying oven drying time is considerably reduced. To avoid oxidation, an inert gas(e.g. nitrogen) can be fed into the chamber.

Application:

Vacuum Drying Oven is widely applied in research and application fields such as biochemistry, chemical pharmaceutical, medical and health, agricultural scientific research, environmental protection and so on, for drying, baking powder and all kinds of glass containers disinfection and sterilization. Particularly suitable for the dry heat sensitive, easy to decompose, easy oxidation material and complex component objects processing fast and efficient drying treatment.

Many samples are susceptible and tend to be damaged by the drying process. The drying process in the vacuum drying chamber reduces this risk to a minimum. This method aims to gently dry a high-grade product that contains water or a solvent without altering its properties in the process. When drying under a vacuum, the pressure in the drying chamber is reduced so that water or solvents evaporate even at low temperatures.

Micro-computer control (with timing)

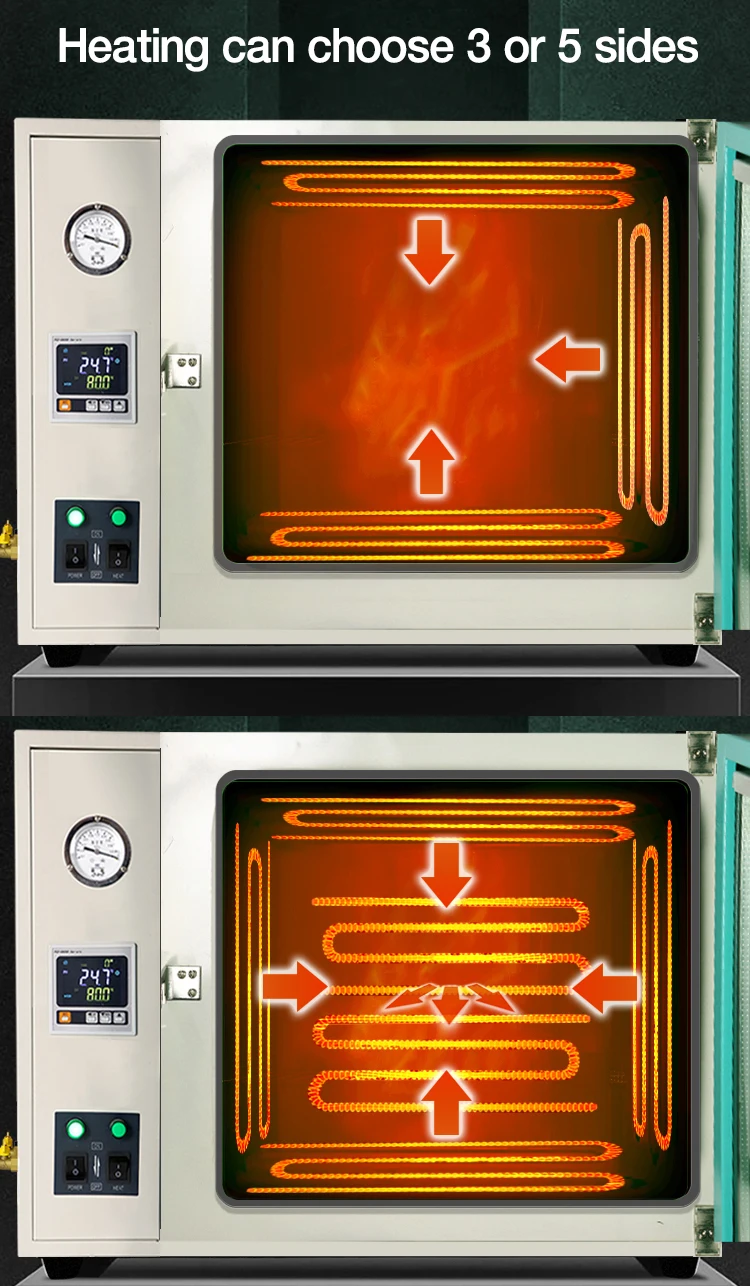

A new generation of Vacuum and Drying Ovens, set the company success in terms of body heat test for many years, through continuous study, breakthrough the traditional technology creative solve the "bottleneck" in the process of heat conduction--find the perfect way of heat transfer. (Minimum energy loss < 6210, 6090, 6030, 6090, 6030 > heater are located in the inner shelf, minimize heat loss.)

Characteristics:

(1)Heat treatment of combustible and explosive solvents

(2)Specially for the drying of lacquers and other coating materials

(3)Square design, make full use of space, more economic, affordable

(4)Natural convection and forced air circulation

(5)High quality materials

|

Model |

DZF-6010 |

DZF-6020 |

DZF-6050 |

DZF-6090 |

DZF-6210 |

|

Liner Material |

304 Stainless Steel |

||||

|

Temp. Range |

RT+10~200°C |

||||

|

Max. Vacuum Degree |

0.098 Mpa |

||||

|

Temp. Stability |

±1.0°C |

||||

|

Temp. Analysis |

0.1°C |

||||

|

Working Temp. |

+5~40°C |

||||

|

Input Power (W) |

400 |

800 |

1400 |

2000 |

2400 |

|

Chamber Capacity (L) |

8 |

25 |

55 |

90 |

215 |

|

Inner Dimension (W*D*H,mm) |

200*200*200 |

300*280*300 |

410*400*340 |

450*450*450 |

560*600*640 |

|

Overall Dimension (W*D*H,mm) |

600*400*430 |

620*500*480 |

720*570*540 |

770*620*710 |

730*730*1800 |

Why choose us!

-with 6 years foreign trade,and over 30 years domestic trade in China.

-we are professional mancufacturer in chemical industry!

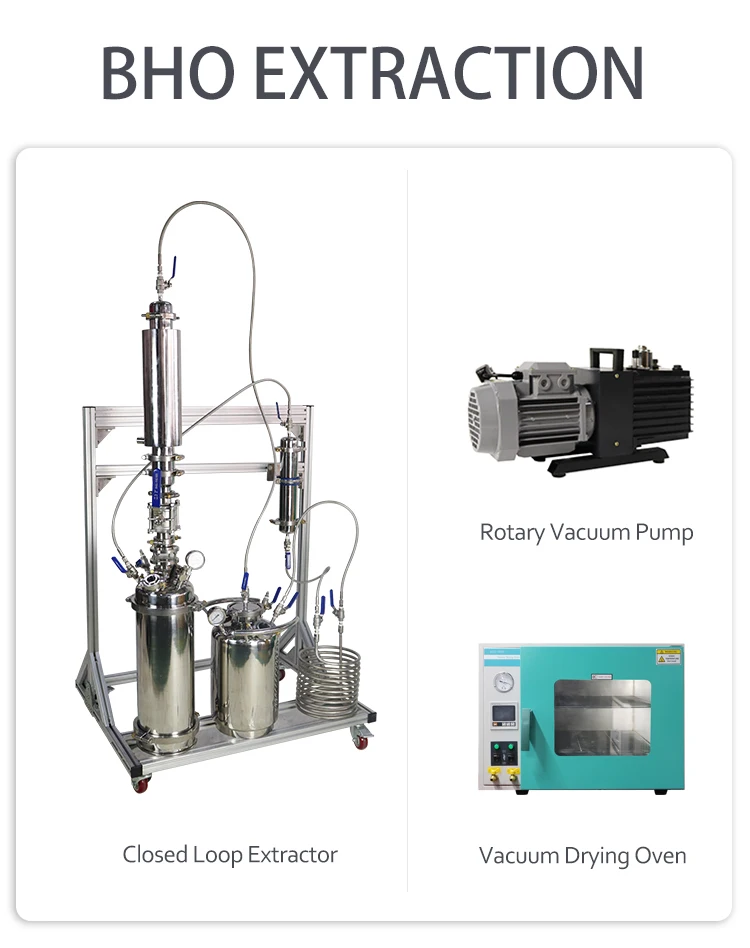

-our main product is rotary evaporator, glass reactor, vacuum drying oven and their matched equipments.

-our customers are all over the world, mainly spread in America, Canada, India,and so on.

Warranty & Service:

Pre-service

24 Hours online service for your consult.

Help choose right model,and a series of service,person,advise.

Middle service

--Give you best offer

--Provide discount for many sets order

--Do customer's request:

--Choose payment term you convienent.

--Promptly production and delivery,inform you in time.

--Can provide invoice value as you like to decrease your tax.

After sale service

--1 year warranty service and all life maintenance.

--Technical Egineer are avalible for oversea trainning.

--Free change for some parts

--Remote control technical consult

--Free installation DVD

--Maintenance plan

Packaging:

-The glass parts will be wrapped with foam,then put into the carton; the mainbody portion will be packed in wooden cases;

-Both neutral and customized packaging can be available.

Shipping:

-We can ship the goods to you by International Express such as DHL,UPS,TNT,EMS and so on, you can also choose the appropriate one based on your timeline and budget. Besides,you can choose to use your own shipping agent.

| Shipping method | Note |

| Express | Door to door, very convenient, don't need to clearance or pick-up |

| By air |

Airport to airport, you need to do the customs clearance and pick up the goods at your local airport, which you can have a local shipping agent to do for you. |

| By sea | Port to port and you need to do the customs clearance and pick-up the goods

at your local port, which you can have a local shipping agent to do for you. |

Company introduction:

Zhengzhou Keda Machinery and Instrument Equipment Co., Ltd. is specialized in R & D, production, sales, teaching and chemical biology pharmacy equipment integrated company. The main products are rotary evaporator, jacketed glass reactor, single layer glass reactor, circulating water vacuum pump, low temperature reaction bath (slot), low temperature cooling fluid circulating pump(cool chiller), vacuum drying oven, blast drying oven, freeze dryer, water/oil bath, magnetic heating stirrer, overhead mixer, ultrasonic cleaning machine, lift platform, etc. Besides, we act as agents of some domestic and foreign famous enterprise products, sustaining high praise in domestic junior colleges and universities, scientific research units, etc. Our products are sold to USA, Australia, Asia, Brazil,Egypt etc. countries and our customers have been fully affirmation.

Factory Size: 1,000-3,000 square meters

Year Established: 2009

Total Revenue : US$1 Million - US$2.5 Million

Registration No.: 410105000067362

Main Markets: Central America, Mid East, Oceania, Africa, South America

Please click on the picture:

1. How many shelves does your drying oven can hold?

Different models hold different number shelves like 1, 2, 3, 4 shelves. That will be according to the models.

2. What is your max temperature?

Max 250 degree C, 200 degree C is normal.

3. What kind of size do you have?

We have 8L(0.28 cu ft), 25L(0.9 cu ft), 55L(1.9 cu ft), 91L(3.2 cu ft), 215L(9cu ft). They are normal and popular models. If you need bigger size we can supply it too.

-

Best quality 10kg 15kg freeze dryer food drying freeze dryer price household oil-free vacuum pump usa ready stock

-

Vacuum freeze dryer price

-

Household 6kg 8kg fruit food mini vacuum drying household freeze dryer freeze dryer with vacuum pump machine US spot

-

Mini Vacuum Freeze Dryer For Sale

-

Digital Display Multifunctional Combination 8 in 1 Heat Press Machine Sublimation Printing T-shirt Cup Tray Hat Printing

-

Vacuum drying machine, milk powder for vacuum drying

-

Factory price mini industrial vacuum food freeze dryer price

-

220V / 110V Household Professional Food Dehydrator Fruit Dryer

-

Stainless Steel Vacuum Chamber Vacuum Degassing Chamber Glass Cover Silicone for Evacuating and Protecting Food

-

2019 China Laboratory Industrial Small Freeze Dryer Price For Sale

Other Products

-

$100.00 / set

$100.00 / set -

$2200.00 / set

$2200.00 / set -

ZZKD glass laboratory equipment vacuum distillation system kit 2l 5l 10l 20l short path distillation$475.00 / set

ZZKD glass laboratory equipment vacuum distillation system kit 2l 5l 10l 20l short path distillation$475.00 / set -

$3300.00 / set

$3300.00 / set -

$250.00 / set

$250.00 / set -

$250.00 / set

$250.00 / set -

$2800.00 / set

$2800.00 / set -

$8000.00 / set

$8000.00 / set -

$10000.00 / set

$10000.00 / set -

$2800.00 / set

$2800.00 / set