Xinnuo eps sandwich panels machinery sandwich panel production line

-

Supplier: Hebei Xinnuo Roll Forming Machine Co., Ltd. -

Region: Hebei, China -

Contact: Ms linda Li -

Price: $30000.00 /set -

Min. Order: 1 set

| Roller Diameter of roll forming part: | 80mm; | Local Service Location: | None; |

| Machinery Test Report: | Provided; | Core Components: | 报警锁; |

| Applicable Industries: | Building Material Shops,Manufacturing Plant,Construction works ; | Brand Name: | xinnuo; |

| Warranty: | 1 Year; | Supply Ability: | 10 Set/Sets per Month eps sandwich panels machinery sandwich panel production line; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,cash; | Warranty of core components: | 1 Year; |

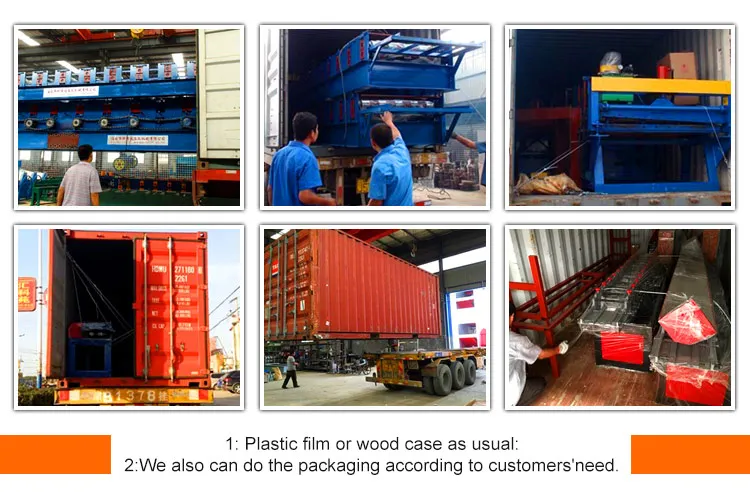

| Packaging Detail: | Xinnuo eps sandwich panels machinery sandwich panel production line The roller package is plastic film, The machine is nude in the container; | Core thickness: | 20-300mm; |

| After-sales Service Provided: | Engineers available to service machinery overseas,Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; | Place of Origin: | Hebei China; |

| Cutter: | fly saw; | Product name: | Xinnuo eps sandwich panels machinery sandwich panel production line; |

| total power: | 30kw; | Roller material: | 45# steel; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Condition: | New; |

| Video outgoing-inspection: | Provided; | Main Frame of plate forming machine: | 300mm H-Beam; |

| Backboard Thickness of plate former: | 20mm; | Feeding Thickness of plate: | 0.3-0.8mm; |

| Port: | Tianjin Port; | Marketing Type: | Hot Product 2019; |

| Showroom Location: | None; |

Xinnuo eps sandwich panels machinery sandwich panel production line

Main parameters

Customized according to customer requirements

|

No. |

main parameter of Sandwich panel forming machine line |

||

|

1 |

Suitable to process |

Color steel plate |

|

|

2 |

Width of the plate |

1000&1200mm |

|

|

3 |

Rollers |

17-44rows |

|

|

4 |

Dimensions |

38.0*2.25*2.5m |

|

|

5 |

Power |

30kw |

|

|

6 |

Thickness of the plate |

0.3-0.8mm |

|

|

7 |

Productivity |

2-6m/min |

|

|

8 |

Diameter of the roller |

Φ90mm |

|

|

9 |

Weight |

About 15 T |

|

|

10 |

Voltage |

380V 50Hz 3phases |

|

|

11 |

Material of the cutting plate |

Cr12 |

|

|

12 |

Processing precision |

Within 1.00mm |

|

|

13 |

Control system |

PLC control |

|

Technical parameters

|

sandwich panel standards |

|

|

Length |

Min cut length: 3 m |

|

raw material standards |

|

|

Coil thickness |

0.4~0.6mm (the coil surface should be flat, no arch and the others surface trouble.) |

|

Material coil yield strength |

235MPa |

|

Material coil max width |

see detailed profile drawings. |

|

Material coil max weight |

5 T |

|

Material coil inner diameter |

Φ508,Φ610 mm |

|

EPS core material |

|

|

density |

≥18Kg/m3 |

|

straight rate |

≤1mm/m |

|

arch degree |

≤3mm/m |

|

panel surface |

shoule be flat no flat degree is ≤1.5mm/m, |

|

sandwich panel length |

longer than 5 meters |

|

wool material |

|

|

fiber length |

≥100mm |

|

cubage density |

≥100Kg/m3 |

|

sandwich panel length |

≥3 meters |

2. Processing technique and deployment

Processes: Composite Decoiler—Roll Forming—laminating system (ribbon, gelatinizing, heating up, compounding, crimping, notching, edge trimmer)—cutting system—Runout Table

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

-

CANMAX Manufacturer Construction Engineering High Quality 12m Manual Electric Concrete Pump Spare Parts Mobile Concrete Spreading Arm

-

Prefab Modular House Prefab Prefab House Equipment China 2021

-

China Manufacturer Manufacturing Machine Technology Production Line Guide Rail Telescopic Channel Roll Forming Machine Drawer Slide

-

Earthquake Resistant Precast Concrete House Making Machine, Structural House Equipment

-

160L 280L 350L Tilt Drum Concrete Mixer Mobile Mini Cement Mixer Price

-

Best Selling Roller Shutter Slat Forming Machine / Roller Shutter Door Making Machine

-

Washbasin Pedestal Bathroom Casting Battery Stand

-

modern concrete house machines, fully prefab concrete houses

-

Building materials manufacturing machinery PU sandwich panel machine

-

Price of machine for forming rolls of production line of continuous polyurethane sandwich panels factory customized with ISO9001 / Ce / Sonc

Other Products

-

$9000.00 - $22000.00 / set

$9000.00 - $22000.00 / set -

$40000.00 - $50000.00 / set

$40000.00 - $50000.00 / set -

$58000.00 - $65000.00 / set

$58000.00 - $65000.00 / set -

$42000.00 / set

$42000.00 / set