Automatic Changed CZ Purlin Roll Forming Machine with PLC Control System Roller Form Machine

-

Supplier: Hebei Xinnuo Roll Forming Machine Co., Ltd. -

Region: Hebei, China -

Contact: Ms linda Li -

Price: $42000.00 /set -

Min. Order: 1 set

| Payment Terms: | L/C,T/T,cash; | Key Selling Points: | Easy to Operate; |

| Weight: | About 10T; | Dimension(L*W*H): | About 8500*1000*1400mm; |

| Warranty: | 12 months; | Power(W): | 15 kw; |

| After-sales Service Provided: | Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support; | Backboard Thickness of plate forme: | 25mm; |

| CONTROL SYSEM: | PLC AUTOMATIC CONTROL; | roll forming machine: | c zchannel steel c z purlin roll forming machine; |

| Condition: | New; | Voltage: | 380v,50hz,3 phrases; |

| Warranty: | 12 months; | Brand Name: | Xinnuo; |

| Certification: | CE/ISO; | Production Capacity: | 12-22m/min; |

| LIFE TIME: | 10 YEARS; | Applicable Industries: | Building Material Shops,Machinery Repair Shops; |

| Feeding Thickness of plate: | 1.5-3.0mm; | USE: | C&Z; |

| Type: | Steel Frame & Purlin Machine; | Cutter material: | Cr12 , quenched; |

| Main Frame of plate forming machine: | 360mm H-Beam; | Place of Origin: | Hebei China; |

| Supply Ability: | 30 Set/Sets per Month c z purlin roll forming machine; | Work Pressure: | 350MPA; |

| Port: | tianjin; | Packaging Detail: | Automatic Changed CZ Purlin Roll Forming Machine with PLC Control System Roller Form Machine. Main machine is nude in the container, the computer control box is packed with wooden packaging.; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | roller material: | GCr15; |

Made in cn c z section frming machine / c zchannel steel c z purlin roll forming machine

Equipment components:

Equipment components:

Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting

Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable.

C Z Purlin Roll Forming Machine Main parameters

1.Echnical parameters

1. | Configurations | Manual Uncoiler, Guiding Platform, 9 Shaft Strip Leveler, Main Machine Of Roll Forming, Hydraulic Motor, Pre-Punching Device,Pre-Cutting Device, Hydraulic Station, PLC Control, Supporter Table. |

2. | Control System | PLC Inverter Encoder Touch Screen |

3. | Main Frame | 400mm H-Beam |

4. | Total Power | 22 kw |

5. | Power Supply | 380V, 3-Phase,50Hz |

6. | Forming Speed | 12-24m/min |

7. | Roll Station | 18 stands |

8. | Roller Diameter | 80mm |

9. | Effective Width | 80-300mm |

10. | Feeding Thickness | 1.5-3.0mm |

11. | Backboard Thickness | 20mm |

12. | Cutter Standard | GCr12 |

13. | Roller Standard | Gcr15# |

14. | Overall Size | About 8500×1000×1400mm |

15. | Total Weight | About 10T |

16. | Custom | According to customer's requirements |

NOTE: All technical parameters can be changed according to user s need, and only as a reference.

2.C Z Purlin Roll Forming Machine Components specification

(1) Manual Uncoiler

Max.Capacity:5T

(2)Pre- Cutting Device& Pre-Punching Device

It adopts hydraulic motor drive and PLC computer-controlled to fix length of die cutting.

Cutting length tolerance:±2mm

Material:GCr12 with quenched treatment 60-62°C

(3)Hydraulic System

Match equipment: Electro motor, a set of hydraulic tank, a set of hydraulic oil pump, and electromagnetic valve.

Power: 22 KW

(4)Control System

It adopts PLC control system, Color Touch Screen; the target length can be adjusted by it.

Computed mode: automatic or manual

(5)Encoder

The counter gauges length, and modulates pulses.

(6)Simple Stack

It is used for loading the formed plate.

Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract value to be paid by T/T after inspection by buyer in seller's factory while before delivery.

Delivery: 30 days after receipt of advance payment

Service: we send technician to your country to fix the machine.The buyer should bear all the cost including: visa, Round trip tickets and suitable accommodation, also buyer should pay salary 80USD/day.

Warranty: 12 months limited warranty

During warranty: parts are free but buyer pay for the shipping fee.

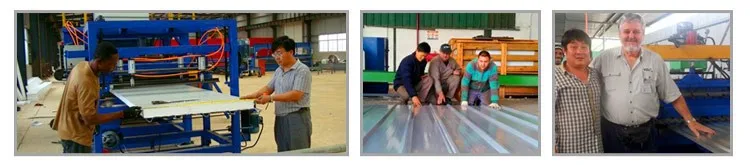

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C Z Purlin Roll Forming Machine , highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Strong technical resources are the most stable guarantee for our products' quality. We adopt computer software for design drawing, production drawing and installation drawing for steel construction equipment. We adopt advanced computer digital inspection and produce high quality light steel structure equipment. Our technical is updating day by day!

Our sales network covers all over China. We also sell products to the United States, Australia, the Netherlands, Germany, Ecuador, Bolivia, Thailand, Malaysia, Indonesia, India, the Philippines, Bangladesh, Nigeria, South Africa, Ethiopia, Syria, Libya, Ghana, Sudan, Saudi Arabia, the United Arab Emirates, Turkey, Azerbaijan and other markets.

Our company has matured after-sale service network, we could provide efficient and satisfactory service for you throughout the period of our cooperation.If necessary, we can supply you with local technical support and send technicians to for installation and operation training.

-

High speed metal roll forming machine and track

-

c light keel forming frame cad light steel machine

-

House light steel villa light steel keel forming machine

-

Electrical Cabinet Shelf Roll Forming Machine Using Elephant Roll Forming Technology

-

Light steel keel equipment keel rolling forming frame dividing machine

-

Popular c panel channel steel stud light weight keel equipment roll forming machine

-

metal frame for making drywall drywall, stud rolls, cu shaped light keel forming machine

-

Precast Concrete Fence H Beam Making Machine After Precast Concrete Fence

-

Gypsum Board Ceiling Steel Fur Channel Forming Machine Omega Channel Forming Machine

-

PLC controlled steel CZ purlin roll forming machine for quick replacement

Other Products

-

$9000.00 - $22000.00 / set

$9000.00 - $22000.00 / set -

$40000.00 - $50000.00 / set

$40000.00 - $50000.00 / set -

$58000.00 - $65000.00 / set

$58000.00 - $65000.00 / set -

$30000.00 / set

$30000.00 / set