c light keel forming frame cad light steel machine

-

Supplier: Haixing (tianjin) Imp. & Exp. Co., Ltd. -

Region: Tianjin, China -

Contact: Ms Alin Zhao -

Price: $14500.00 / 1 - 2 sets

$14000.00 / 3 - 9 sets

$13000.00 / 10 - 19 sets

$12000.00 / >=20 sets -

Min. Order: 1 set

Product details

| weight: | 1750 kg | Production capacity: | 50-40m/min |

| product name: | c light keel forming frame cad light steel machine | Main selling points: | easy to operate |

| type: | Steel frame purlin machine | Applicable industries: | Building material stores, machine repair shops, manufacturing plants, construction projects |

| Health status: | new | Shaft material: | 45 # steel |

| Introduction: | According to customer requirements | Cutting blade material: | Cr12mov |

| Origin: | Tianjing, China | strength: | 5.5kw+4kw |

| Marketing Type: | New Products for 2021 | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, pump |

| Material Thickness: | 0.3mm-1.2mm | Supply capacity: | 1 set per month |

| Warranty: | 1 year | port: | Tianjin Qingdao Shanghai Yiwu |

| Package preview: | Shaft diameter: | Solid 50mm | |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, PayPal | Dimensions (L*W*H): | About 5900*1200*1500 |

| brand: | starfish | Mechanical test report: | if |

| Video outbound inspection: | if | Operating language: | English/Spanish/Chinese |

| Main frame: | Steel plate weld | main motor power: | 5.5 kW |

| Showroom location: | not any | Core component warranty: | 1 year |

| Packaging Details: | a. The main body of the machine is made of waterproof plastic, and then fixed on the container with a steel wire with a diameter of 8mm and an angle iron. b. Rollers and shafts are coated with anti-rust oil. c.PLC control system and motor pump are packed with waterproof paper and plastic film. d. Spare parts in the carton. e. Manual uncoiler bare package. f. Put the output table into the carton. g. If the machine is too long, we will divide it into two parts and pack them in one package with steel wire. h. Suitable for shipping by sea. | Voltage: | 380V/50HZ three-phase (or customized) |

| raw material: | steel belt |

Light Steel Frame Machine Specifications

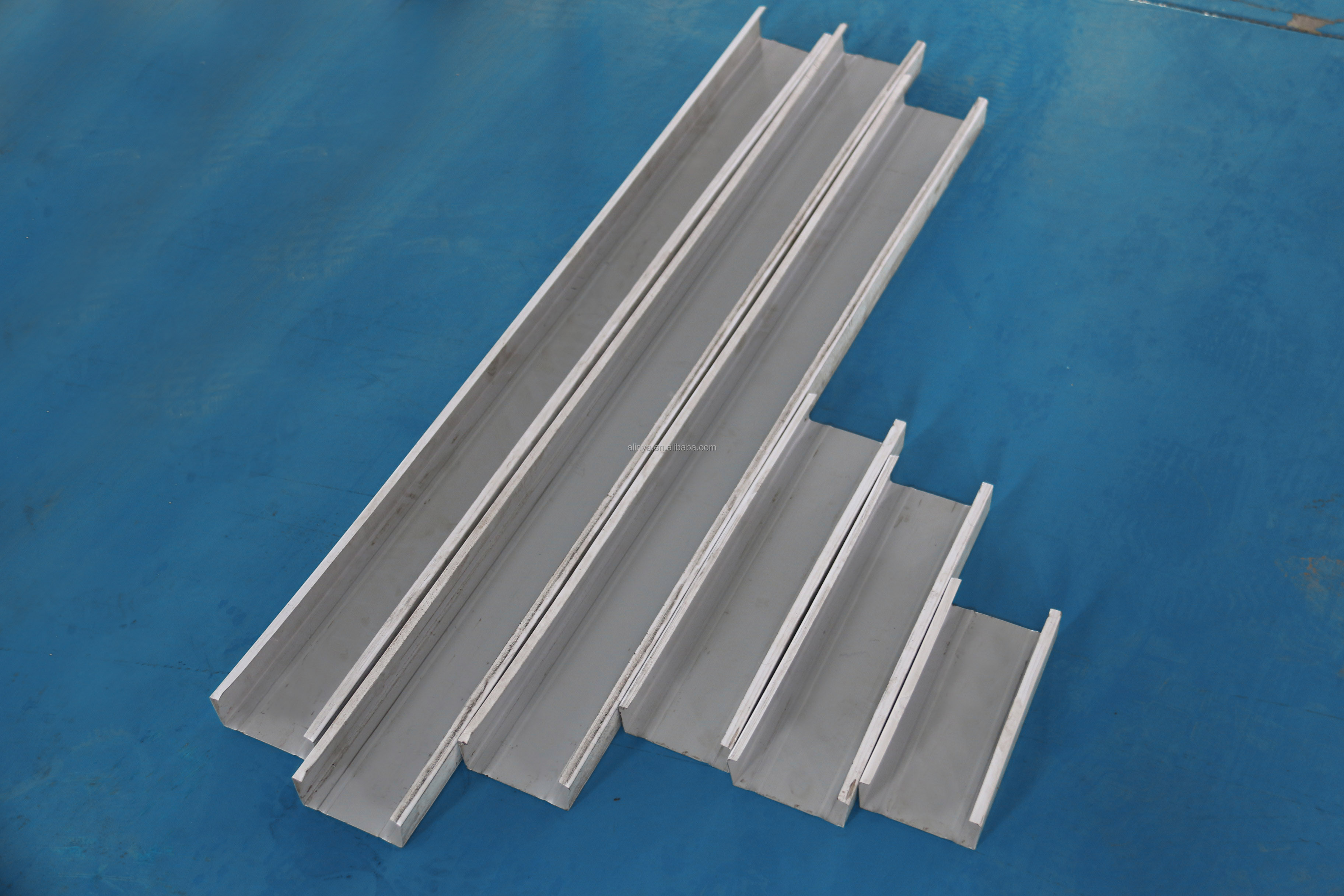

*c light keel forming frame cad light steel machineIt is a steel frame cold rolling mill that can realize continuous automatic production. Light steel frame forming production line includes uncoiler, forming system, punching equipment, cutting equipment, hydraulic station, electrical control system. The light steel forming production line adopts PLC control and AC frequency conversion speed regulation technology to realize automatic continuous production.

*c light keel forming frame cad light steel machineEnergy-saving and efficient production of steel structure equipment.

Machine parameters

| |

product name | c light keel forming frame cad light steel machine |

suitable for processing | steel belt |

Control System | Delta PLC control system |

Shaft diameter | 50 mm |

Sheet thickness | 0.3-1.2mm |

Hydraulic motor power | 4 kW |

Roller standard | 45# steel chrome plated heat treatment |

cutting blade | Cr12mov |

main power | 5.5 kW |

Voltage | 380V 50Hz 3-phase (220v or 440v or customized) |

total measurement | About 5500*1200*1500 |

work process:

Forming process: uncoiler→roll forming→cutting head→ Collect products.

Coil inner diameter 470-530 (mm)

Coil outer diameter 1500(mm)

Bearing capacity: up to 3t

Language: Chinese/English/Russian/Spanish

PLC control table

Components: touch screen operation interface and electrical system frequency converter.

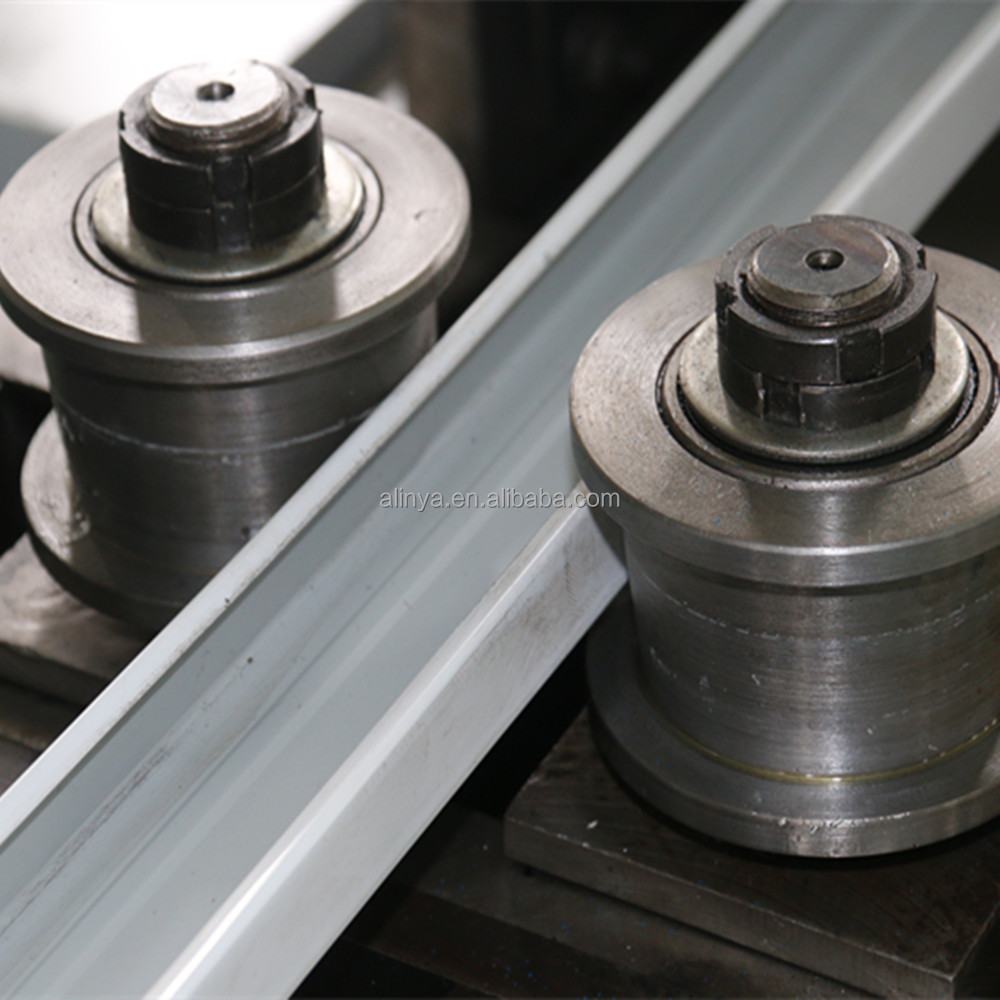

Name: Main Roller

Roller material: Cr12, quenching, hardness HRC56-82° Transmission mode: gear transmission Frame panel thickness: 7mm Shaft material: 45# forged steel Main frame plane: thickness 22mm, finishing Feed positioning: manual positioning, flexible at both ends

Blade material: Cr12MOV,

Cutting method: hydraulic cutting

Uses: High-quality cutting materials make the cutting surface neat and burr-free

Name: servo motor

Power: 1.5kw

Wake up: Make the cutting head cut the product while moving.

usage:

1.The cutting head adopts high-quality electro-hydraulic cutting system,automatic GPS

2. High efficiency, can produce 25-40m per minuteContinuous cutting without deceleration

Structure: steel cube welded, screwed

usage:

1. The upper shaft can be rotated to facilitate the accumulation of raw materials without causing product damage.

2. Height adjustable, easy to gather products.

Quantity: 2 sets (one set is 3m long)

1. The upper shaft can be rotated to facilitate the accumulation of raw materials without causing product damage.

2. Height adjustable, easy to gather products.

Quantity: 2 sets (one set is 3m long)

International brand accessories

Don't worry when the parts of the machine are aging due to long-term use. We use all international brand accessories, you can quickly buy the same one locally! ! !

c light keel forming frame cad light steel machineAdvantage:

***Fully automatic control system with PLC.

***Simple operation: enter the length and quantity on the control panel.

***One year free warranty, more than one year, if any parts broken, please tell us and pay us, we will deliver any parts you need. And support the technical skills of the machine for life.

***One year free warranty, more than one year, if any parts broken, please tell us and pay us, we will deliver any parts you need. And support the technical skills of the machine for life.

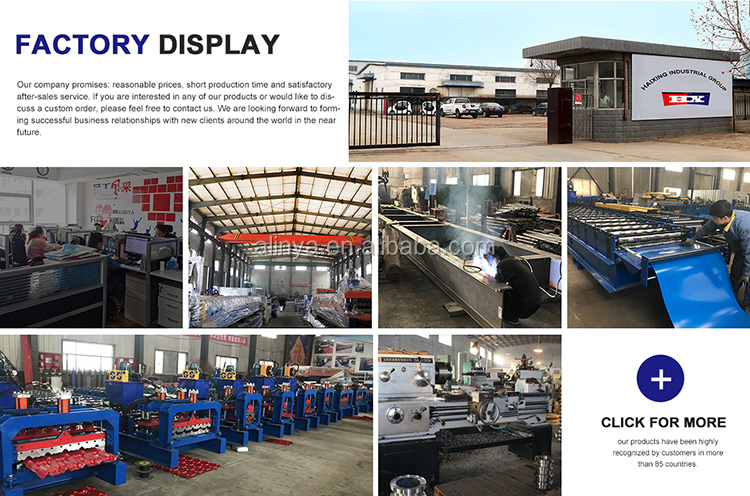

about Us

Tianjin Haixing is a professional manufacturer of cold roll forming machines, we have specialized in this field for 22 years. Our equipment includes roof forming machine, floor deck forming machine, automatic decolorizing machine, rolling door forming machine, lightweight keel forming machine, purlin machine, leveling machine,and slitters, andOther related construction equipment.

Haixing has a team of engineers with more than 20 years of experience. at the same time, Our machines use branded electrical components, raw materials come from branded steel mills, strict process control, two-year warranty, installation and training services.

We have served customers in 85 countries and provide solutions based on your local hot-selling models, such as Germany, the United States, Mexico, Chile, Bolivia, Italy, Australia, Kuwait, Saudi Arabia, South Korea, Japan, South Africa, Kenya and other 65 countries in different regions. We have rich experience in the needs of different countries, such as profiles, thickness ranges, uses, installations, etc. Company tenet: technological innovation, customer center, win-win. Thank you for your trust and choice, we will provide you with the best service support and help you achieve greater success. Looking forward to more cooperation with new and old friends all over the world.

Packaging and Shipping

a. The main body of the machine is made of waterproof plastic, and then fixed on the container with a steel wire with a diameter of 8mm and an angle iron.

b. Rollers and shafts are coated with anti-rust oil. c. PLC control system and motor pump are packed with waterproof paper.

plastic film.

d. Spare parts in the carton.

e. Manual uncoiler bare package.

f. Put the output table into the carton.

g. If the machine is too long, we will divide it into two parts and pack them in one package with steel wire. h. suitable for the ocean

shipping.

b. Rollers and shafts are coated with anti-rust oil. c. PLC control system and motor pump are packed with waterproof paper.

plastic film.

d. Spare parts in the carton.

e. Manual uncoiler bare package.

f. Put the output table into the carton.

g. If the machine is too long, we will divide it into two parts and pack them in one package with steel wire. h. suitable for the ocean

shipping.

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service awareness, specializing in exporting various types of cold roll forming machines.

Q: Can one machine only produce one style of panel profile?

Answer: Not complete. Suitable for wider double deck manufacturing machines. More than 3 panels can be produced.

Q: How long does it take to manufacture the machine?

A: Generally, machines can be finished within 20 to 45 working days. But if you need the machine urgently, we can save your time.

Q: Is there any quality control when the production line is produced?

A: Yes, we have a team responsible for quality control, including laying of raw materials, processing of parts such as rolls, processing of roll faces and shafts, assembly, testing and packaging.

Q: What can you do if the machine is broken?

A: Our machine warranty is 24 months. If the damaged parts cannot be repaired, we can send new parts to replace the damaged parts, but you need to pay the express fee by yourself. If the warranty period is exceeded, we can negotiate a solution and provide technical support for the entire life cycle of the equipment.

Q: What is your advantage compared with other suppliers?

A: We will provide you with the best service. We will give you good advice beyond your requirements. These lines are easy to install and require low maintenance.

Q: Can we be your agent abroad?

A: Of course, if you have the business of roll forming line, we will welcome a lot of cooperation.

A: We are a factory with a professional production team and service awareness, specializing in exporting various types of cold roll forming machines.

Q: Can one machine only produce one style of panel profile?

Answer: Not complete. Suitable for wider double deck manufacturing machines. More than 3 panels can be produced.

Q: How long does it take to manufacture the machine?

A: Generally, machines can be finished within 20 to 45 working days. But if you need the machine urgently, we can save your time.

Q: Is there any quality control when the production line is produced?

A: Yes, we have a team responsible for quality control, including laying of raw materials, processing of parts such as rolls, processing of roll faces and shafts, assembly, testing and packaging.

Q: What can you do if the machine is broken?

A: Our machine warranty is 24 months. If the damaged parts cannot be repaired, we can send new parts to replace the damaged parts, but you need to pay the express fee by yourself. If the warranty period is exceeded, we can negotiate a solution and provide technical support for the entire life cycle of the equipment.

Q: What is your advantage compared with other suppliers?

A: We will provide you with the best service. We will give you good advice beyond your requirements. These lines are easy to install and require low maintenance.

Q: Can we be your agent abroad?

A: Of course, if you have the business of roll forming line, we will welcome a lot of cooperation.

Project case

1. Ridge tiles are rich in color, classical and elegant, used for glazed tiles, and are the finishing touch for modern times

architecture.

2. Light weight, high strength, good water resistance and easy installation. Special material or sheet thickness,

Machines can be customized according to customer requirements. It can be widely used in villa roofs, urban flat slopes, tourist scenic spots, etc.

architecture.

2. Light weight, high strength, good water resistance and easy installation. Special material or sheet thickness,

Machines can be customized according to customer requirements. It can be widely used in villa roofs, urban flat slopes, tourist scenic spots, etc.

VIEW MORE

You may like

-

High speed metal roll forming machine and track

-

House light steel villa light steel keel forming machine

-

Electrical Cabinet Shelf Roll Forming Machine Using Elephant Roll Forming Technology

-

Light steel keel equipment keel rolling forming frame dividing machine

-

Popular c panel channel steel stud light weight keel equipment roll forming machine

-

metal frame for making drywall drywall, stud rolls, cu shaped light keel forming machine

-

Precast Concrete Fence H Beam Making Machine After Precast Concrete Fence

-

Gypsum Board Ceiling Steel Fur Channel Forming Machine Omega Channel Forming Machine

-

PLC controlled steel CZ purlin roll forming machine for quick replacement

-

XHH C89-5S Lgsf Lgs House Price Keel Weight Lsf Roll Light Gauge Form Steel Frame Machine For House Construction

Other Products

-

$6500.00 - $9850.00 / set

$6500.00 - $9850.00 / set -

$15000.00 - $29000.00 / set

$15000.00 - $29000.00 / set -

$6000.00 - $9000.00 / set

$6000.00 - $9000.00 / set -

$6200.00 - $9500.00 / set

$6200.00 - $9500.00 / set -

$7000.00 - $10500.00 / set

$7000.00 - $10500.00 / set -

$5500.00 - $9800.00 / set

$5500.00 - $9800.00 / set -

$3500.00 - $7500.00 / set

$3500.00 - $7500.00 / set

Related Search

light steel screw suppliers

frame cad machine

laser lights show machine

metric stainless steel machin screw suppliers

304 stainless steel machine screws pan head

galvanized steel machine omega

automat steel machin screw suppliers

cnc stainless steel machining part

perforated steel machine

drum steel machine