Customized WCB Full Bore Flanged End Welded Pneumatic Or Electric Operated Ceramic Ball Valve Price

-

Supplier: Suzhou Lov Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Rick Huang -

Price: $200.00 /piece -

Min. Order: 1 piece

| Structure: | BALL; | Delivery Detail: | Shipped in 30 days after payment; |

| Pressure: | Medium Pressure; | Medium: | Sea Water, Oil, Gas, Steam, Corrosive Fluid; |

| Material: | Ceramic; | Media: | Acid; |

| Temperature of Media: | Normal Temperature; | Standard: | ISO 17292/API 6D/DIN; |

| Standard or Nonstandard: | Standard; | Power: | Manual; |

| Model Number: | Ceramic Ball Valve; | Application: | Corrosive Fluid; |

| Body material: | Monel, Inconel, Incoloy, Hastelloy, Titanium, Nickel Aluminum bronze; | Certificate: | ISO,API,CE,TS; |

| Brand Name: | LOV&OEM; | Original Country: | China Supplier; |

| Supply Ability: | 2000 Piece/Pieces per Month Ceramic Ball Valve; | Place of Origin: | Jiangsu China; |

| Valve Guarantee: | 18 Months after shipment; | Port Size: | 1/2~12" (DN15~DN300); |

| Packaging Detail: | Plywood Case for Ball Valve; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Industry: | Power, Chemical, Petroleum, Marine, Offshore,Water Treatment, Mining; | Port: | Shanghai,Ningbo; |

| Connection Type: | RF, RTJ,BW, SW, NPT; | Working Pressure: | 150~600LB (PN16~PN150); |

| Valve Test: | 100%quantity tested before delivery; |

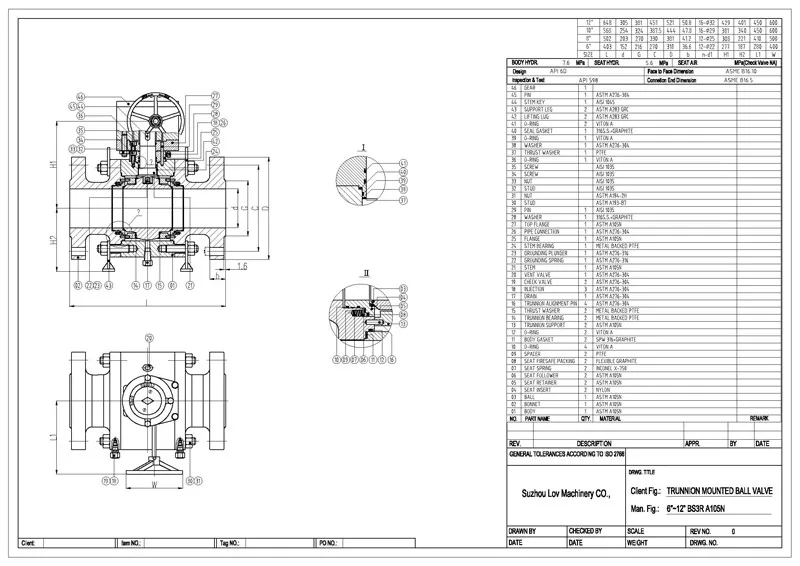

Customized Full Bore Flanged End Welded Ball Valve Price

Product Name:Ceramic Ball Valve

Size:1/2~12" (DN15~DN300)

Working Pressure:150~600LB (PN16~PN150)

Connection Type:RF, RTJ,BW, SW, NPT,WAFER

Medium:Sea Water, Oil, Gas, Steam, Corrosive Fluid

Ceramic Ball Valve

Its our aim to get general arrangement drawings for approval to our customers within one week after order placement.

The strength of LOV is the ability to listen and work closely with customers to provide solutions to process problems.

We focus on valves in standard and special materials as customer request.

Our main materials show as the follows.

Any request for other materials, please contact LOV Machinery sales or engineering team on email or TradeManager.

Special Material | Titanium or Titanium alloy series | Titanium(Gr.2,Gr.3,Gr.5,Gr.7,Gr.12) |

Nickel alloy series | Ni6,Ni200,Ni201 | |

Monel 400,Monel k500 | ||

Inconel 600/625/690/750 | ||

Incoloy 800/825/800H/800HT | ||

Hastelloy B3/C/C4/C22/C276/G30 | ||

Zirconium alloy series | Zirconium 702/703/705 | |

Bronze alloy series | Nickel aluminum bronze C95800 | |

(Super)Duplex Steel | ASTM F51/F53/F55 | |

Other corrosion resistance | Alloy 20,AISI 321,310,904L | |

Normal Material | Carbon Steel | WCB,WCC,LCB,LCC,A105N,LF2 |

Alloy Material(Low Temperature) | LC1,LC2,LC3,LF3 | |

Alloy Material(High Temperature) | WC1,WC6,WC9,C5,C12A | |

Stainless Steel | CA15,CF8,CF8M,CF3,CF3M |

At Lov Machinery,we do business the right way and are committed to manufacturing and stocking the highest quality products.

We stand behind every product we sell, and are pleased to offer an 18 month warranty on all materials and workmanship

Our manufacturing philosophy is to ensure stable quality and just in time delivery.

We have an advanced machining shop. All parts are produced in-house to ensure quality consistency by means of state-of-the-art CNC machining cells,experienced operation team.

The high level of automation throughout the organization helps us to serve the most demanding industries in the world in a very flexible, high quality and efficient manner.

Based on international and domestic industrial standards and customer requirements,

we set up higher internal quality assurance standards to implement comprehensive and full quality management.

We arrange PMI and physical review for all incoming materials.

We strictly performance the hydraulic test for each valve according to the worldwide standards and customer requirements.

Additional test such as X-RAY, LPE, US, Cryogenic and etc can be arranged upon request.

We will never allow any defective products leave from the factory.

Q. what is your payment term?

A: T/T 30% down payment, balance to be paid before shipment. or L/C.

Q: what is your main market?

A:Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, North America, South America,

Q: How about your capacity?

A: SUNVAL equipped20 hot forging machine, 200 CNCS, 30 multi-rotary CNCs,120fitting automatic machining,12gate multi-rotary CNCs, and now we have 5 lean production lines in total.

Q: Can I get samples from your factory?

A: Yes, Samples can be provided.

Q: If products have some quality problem, how would you deal with?

A: We will responsible for all the quality problems.

-

API 6D Split Ball Valve, A105N, 3/4 Inch, 1500LB, BW Ends

-

API 602 Integral Flange Swing Check Valve, 3/4 Inch, CL 300

-

8 Inch Cast Steel Gate Valve Flange End Handwheel Belt Price Steel Gate Valve Belt 150 lbs.

-

Hot selling brass valve China supplier 1/2 inch-2 inch ball valve in stock free sample

-

Best price 4 inch 6 inch valve 110mm pvc ball valve plastic hot water valve

-

CWX-15N DC5v DC12v ADC9-24V AC85-220V Brass SS304 UPVC 2 Way Electric Ball Valve

-

BBQ gas valve for gas grill

-

4-20mA electric actuator provides modulating water flow control 2/3 way ball valve with position feedback

-

Manual 1/2"- 2" Lead Free Brass Ball Valve 600WOG

-

CTF-001MINI large torque electric valve stainless steel upvc brass valve water treatment plant special ball valve butterfly valve

Other Products

-

$300.00 / piece

$300.00 / piece