300kg 500kg Pneumatic Vacuum Glass Lifter

-

Supplier: Shandong Care Machinery Technology Co., Ltd. -

Region: Shandong, China -

Contact: Mr Care Machine -

Price: $2560.00 /set -

Min. Order: 1 set

| Product Name: | Vacuum Lifter for marble; | Brand Name: | Caretech; |

| Certification: | ISO CE; | Applicable Industries: | Building Material Shops,Retail,Construction works ; |

| Marketing Type: | New Product 2020; | After-sales Service Provided: | Engineers available to service machinery overseas,Online support; |

| Video outgoing-inspection: | Provided; | Place of Origin: | Shandong China; |

| Model Number: | CAP300; | Warranty of core components: | 1 Year; |

| Core Components: | Pump; | Lifting height: | 1000mm; |

| After Warranty Service: | Video technical support,Online support; | Dimension(L*W*H): | 1200x1000x950mm; |

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; | Application: | Pneumatic Vacuum Glass Lifter; |

| Lifting weight: | 300kg; | Air pressure: | 0.5-0.8MPa; |

| Turning angle: | 90degree; | Condition: | New; |

| Machinery Test Report: | Provided; | Local Service Location: | None; |

| Showroom Location: | None; | Warranty: | 12 Months; |

Pneumatic Vacuum Glass Lifter

|

Parameters |

|||

|

Model |

CAPL-200 |

CAPL-300 |

CAPL-500 |

|

Rated load |

300kg |

300kg |

500kg |

|

Sucker diameter |

250mm |

250mm |

250mm |

|

Sucker qty |

2 |

4 |

4 |

|

Vertical turning |

0°-90° |

0°-90° |

0°-90° |

|

Horizontal rotation |

360° |

360° |

360° |

|

Weight |

60kg |

80kg |

100kg |

|

Air pressure |

>0.5bar |

>0.5bar |

>0.5bar |

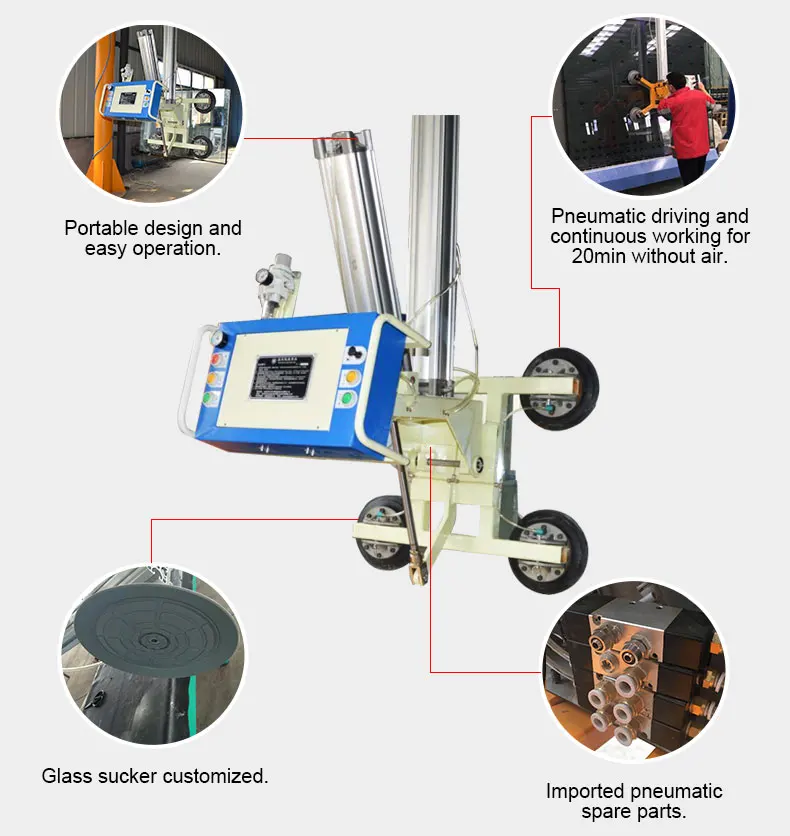

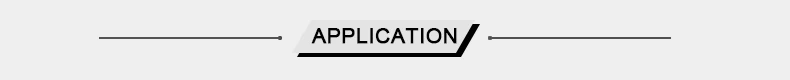

The glass lifter is used for handling and transferring various kinds of glass, and widely used in glass deep processing industry. The lifter is composed of cantilever and handling arm, both part could be customized.

1.Suitable for moving insulating glass /tempered glass/glass curtain wall.

2.Pneumatic glass arm is used to load and unload heavy and hot glass easily. It is easy to carry and very safe and save many labor cost.

3.It features better stability, much safer and more convenient to operate.

4.It could be used in the laminated glass production line, insulating glass production line, mirror glass production line, glass cutting and edging production line and so on.

5.With vacuum pressure charging system, equipment can ensure the whole vacuum system within a relatively constant safe pressure value during transition.

We are quality conscious company, and it’s just our origin to supply customers qualified machines. We are always trying to be the “Solution Expert of Glass Processing Facilities”. We not only supply complete glass processing facilities, but our professional engineer team also provide right facility configuration, accordingly customers’ various production requirements and estimated investment. And we’ll provide essential industrial design and technical guidance as well.

-

Box-type vacuum tube lifting assists the manipulator in lifting and moving

-

400KG~1000KG mini electric vacuum panel lifter for marble stone metal moving

-

Air-conditioning external machine lifting sling hand-shaking lifting bracket lifting crane tool hand-shaking belt self-locking

-

Nemo Patented Design Grabo H V2 Electric Suction Cup Tool Grabo Electric Vacuum Suction Cup Lifter for Glass Tile Wood Wall Stone

-

Factory 200~600kg mini manual vacuum glass suction lifter

-

2022 New Products Portable Electric Suction Cup Heavy Duty Wooden Vacuum Cleaner Grabo Pro Suction Cup

-

800kg 5m lifting height battery stone flipper marble slab granite trolley vacuum wheel lifter glass robot

-

Portable Electric Vacuum Lifter Max. Load 375lbs for lifting wood marble granite glass brick concrete

-

2020 hot selling manual vacuum glass regulator

-

China DAXLIFTER Brand 300-800kg 3.5m Granite Glass Vacuum Lifter

Other Products

-

$8500.00 / set

$8500.00 / set -

$5200.00 / set

$5200.00 / set -

$1450.00 / set

$1450.00 / set -

$1200.00 / set

$1200.00 / set -

$900.00 / set

$900.00 / set -

$2700.00 / set

$2700.00 / set -

$8500.00 / set

$8500.00 / set -

$1200.00 / set

$1200.00 / set -

$4800.00 / set

$4800.00 / set -

$1200.00 / set

$1200.00 / set