Aluminum window cutter with two meters saw

-

Supplier: Shandong Care Machinery Technology Co., Ltd. -

Region: Shandong, China -

Contact: Mr Care Machine -

Price: $5200.00 /set -

Min. Order: 1 set

| spinning speed: | 3100 rpm; | Cutting length: | 400-4200mm; |

| Voltage: | 380V 50HZ; | Certification: | EU standards; |

| Function: | Cutting aluminum profiles; | place of origin; place of origin: | Shandong China; |

| After-sales service provided: | Online support, engineers can repair machinery overseas; | Supply capacity: | 20 sets per month; |

| Cutting Scale: | 135x300mm; | type: | Aluminium window machine; |

| weight: | 1500KG; | Cutting angle: | 45 / 90 degrees; |

| port: | Qingdao Port; | Packaging Details: | 1. Plastic stretch film coating; 2. Steel pallets and plywood bags; 3. LCL or FCL by sea; |

| Applicable industries: | manufacturing plant; | Health status: | new; |

| product name: | Double miter saw aluminum window cutting machine; | application: | window machine; |

| payment terms: | L/C, T/T, Western Union, MoneyGram; | Dimensions (L*W*H): | 5680x1500x1600mm; |

| brand: | nursing technology; | rated power: | 4.4kW; |

| Blade size: | D=500mm; | Main selling point: | High cutting precision; |

| Warranty: | 12 months; |

Double Miter Saw Aluminum Window Cutting Machine

| Voltage | 380V/50HZ | |

| strength | 4.4KW | |

| Working parameters | Saw size | D=500mm d=30mm |

| spinning speed | 2800 rpm | |

| Air consumption | 60L/min | |

| air pressure | 0.5-0.8MPa | |

| cutting scale | width | up to 135 mm |

| high | up to 300 mm | |

| length | 400-4200mm | |

| angle | 45° 90° | |

| dimension | 5800×1250×1700mm | |

| weight | 1800kg | |

1. It is used to cut aluminum door and window profiles, curtain walls and corner connectors;

2. The spindle has high precision and the saw blade rotates smoothly;

3. The interface adopts color touch display screen, which is simple and intuitive;

4. The feeding system adopts imported linear guide rail pair, with high precision and good stability;

5, 45° and 90° cutting optional;

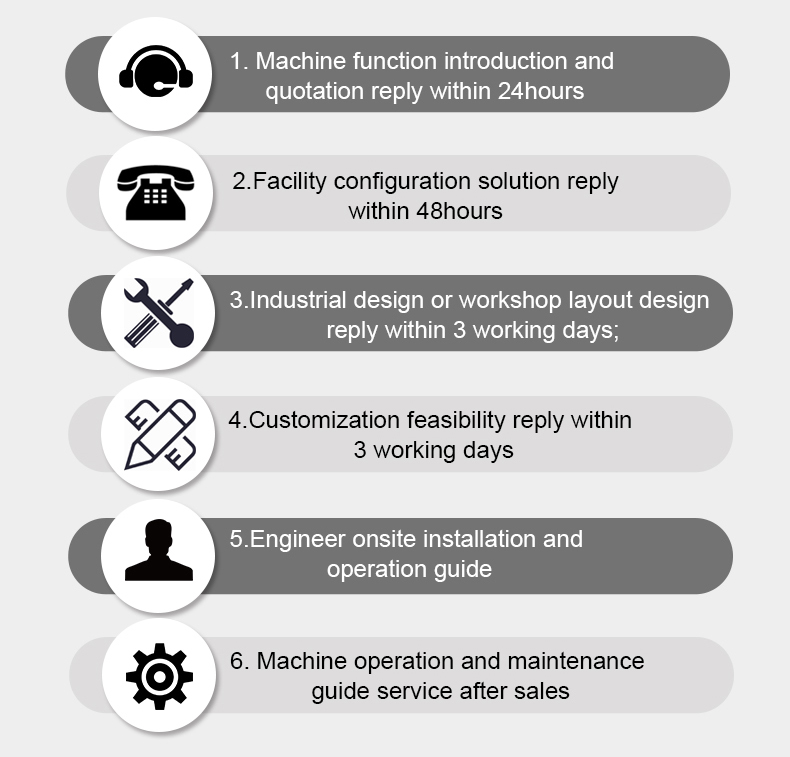

We are a quality-focused company, and providing customers with qualified machines is only our origin. We have been striving to become "glass processing equipment solution experts". Not only do we provide complete glass processing equipment, but our team of professional engineers also provide the correct equipment configuration to meet customers' various production requirements and investment estimates. We will also provide necessary industrial design and technical guidance.

-

Good price 1500w fiber laser cutting machine can cut 1.5mm galvanized sheet

-

CNC Milling Machine with CE XH7124 Mini CNC Milling Machine

-

Electric Shearing Machine Electric Shearing Machine

-

Manual hands and feet electric sheet metal cutting machine guillotine scissors

-

Pipe Hole Saw Cutter Up to 6"

-

732 METAL METAL SAWS

-

Sell English wheel F1.5x1100/English wheel

-

GS-1000 manual shearing machine directly from the factory

-

WFP1000 External Flange Facing Machine Portable

-

MF1520 Pure Grinder Saw Blade Grinder Grinder

Other Products

-

$8500.00 / set

$8500.00 / set -

$1450.00 / set

$1450.00 / set -

$2560.00 / set

$2560.00 / set -

$1200.00 / set

$1200.00 / set -

$900.00 / set

$900.00 / set -

$2700.00 / set

$2700.00 / set -

$8500.00 / set

$8500.00 / set -

$1200.00 / set

$1200.00 / set -

$4800.00 / set

$4800.00 / set -

$1200.00 / set

$1200.00 / set