Agricultural water treatment N45/N52 magnets 15000 Gauss 4''Magnetic water Softener to reduce salt TDS

-

Supplier: Jiangsu YLD Water Processing Equipment Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Iris Wu -

Price: $750.00 /set -

Min. Order: 1 set

| Material for housing: | Mild steel,SS304,SS316,SS316L; | Local Service Location: | Egypt,Saudi Arabia,Thailand,Australia,Morocco,Algeria,Romania,South Africa; |

| Showroom Location: | United States,Saudi Arabia,Mexico,Spain,Morocco,UAE,Algeria,Romania,South Africa,Australia; | Productivity: | 60000L/hr; |

| Supply Ability: | 120 Piece/Pieces per Month; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Food Shop,Construction works ,Energy & Mining,Food & Beverage Shops; |

| Condition: | New; | Water temperature: | 0-80°C (more than 90°C be customized); |

| connection at water inlet: | GB flange,ANSI flange,BSPT,NPT; | Machinery Test Report: | Provided; |

| Core Components: | Pressure vessel; | Video outgoing-inspection: | Provided; |

| material for internal pipe: | SS304,SS316,SS316L; | magnet power: | 3000-3500 Gauss, 6000-8000G,12000 -15000Gauss; |

| Warranty: | 1 Year; | Package Preview: | ; |

| After Warranty Service: | Video technical support,Online support,Field maintenance and repair service; | Payment Terms: | L/C,T/T,Western Union,MoneyGram; |

| working temperature: | 1.0Mpa, 0.6Mpa,1.6Mpa=16bar=233pis,; | Place of Origin: | Jiangsu China; |

| Warranty of core components: | 1 Year; | Marketing Type: | Hot Product 2019; |

| Function: | Remove Salt TDS,scalings; | magnet power loss: | ≤ 30 gauss every year; |

| Brand Name: | YLD; | Weight: | 25Kg/unit; |

| Material: | plywood case; | Packaging Detail: | wooden case packaging into container; |

| After-sales Service Provided: | Video technical support,Field installation, commissioning and training,Field maintenance and repair service,Online support; | Port: | Shanghai(China); |

| Application: | irrigation water, cooling water; | Feature: | High Efficiency,Eco-friendly; |

Magnetic Water Treatment Equipment

(Strong Water Mgnetizer,magnetic scale preventer)

I. Introduction

Magnetic Water Treatment Devices/Softener/Magnetized water equipment

Abstract:

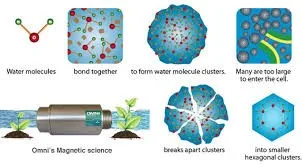

Magnetic water treatment (MWT) is a relatively new technique in environmental management. Magnetic field exposure alters physical and chemical properties of water molecules resulting in unique characteristics. Magnetized water has shown various properties with possible applications in different fields of environmental management. Scale prevention/elimination, soil enhancement, plant growth, crop yield, water saving, and waste water treatment are some of these applications. Magnetic treatment of water restructures the water molecules into tiny, uniform and hexagonally structured cluster easing their travel through the passageways in plant and animal cell membranes. In addition, toxic agents cannot enter the MW structure. These features make MW a bio-friendly compound for plant and animal cells. The present study reviews the applications of MWT in environmental management. The recent advances of MWT in different fields of environment management are discussed. In addition, the mechanism of action of MWT in different applications and future perspectives are discussed.

What is a magnetic water treatment device/softener?

Typically, these devices are permanent magnets or electromagnets that attach to waterlines entering homes and businesses to “purify” or “condition” water supplies. Manufacturers adopt a variety of commercial names for their products from the complex—”patented directional controlled magnet,” “Perm-core,” and “Magnetizer”—to the simple— ”metal bar” or “plug-in treatment device.” Typically, the devices purportedly use electromagnetic fields to change the molecular makeup of various water constituents like calcium and iron to other more “inert” forms. The claimed result is a reduction or elimination of water contaminants. One manufacturer describes the magnetic treatment processes this way, “Water and minerals are subjected to violent intramolecular vibrations and shock at the same time magnetic energy is being added, the mineral’s crystallization is upset and cohesion broken.” Sales representatives often persuade potential customers that they can rely on magnetic treatment devices to provide lifetime, energy-free home water treatment.

II. Working principle

Making use of great energy that generates from neodymium, iron, boron, rare earth and permanent magnetic material, with optimal design, and form a crest vertical center field. When water or fluid flow through the vertical magnetic field, it will produce an electromotive force, the lattice refinement, the original water fouling crystal particle size from about 3.39 microns to about 0.22 microns, flow rate will be faster, the electromotive force generated is greater, the effect is more ideal, to achieve the purpose of anti-scaling and scale removal.

Meanwhile, water flow is treated by magnetic field, lead to the electrical conductivity and osmotic pressure changed and microbial cell ruptured, and cells stop breeding, which achieves effect of sterilization and algae removal.

Since the water treated by magnetic field, it will produce tiny electron flow, which change Fe2O3· NH2O into stable Fe3O4 and generates black magnetic iron oxide which deposited onto the tube wall surface to form a film barrier layer, the oxygen in the water separated from the pipe wall, in this case, it will realize the purpose of rust removal and prevention.

III.Product characteristics:

1. Clear and to prevent pipe scale and rust build

2. Environmental pollution does not use chemicals

3. Not energy, long lifespan for effective running.

4. No expert management of low maintenance costs

5. Small, simple and quick installation

6. Process to achieve zero emissions, save a lot of water

7. Improve the system heat transfer efficiency, energy saving (15% -30%)

8. Descaling process can produce hydrogen peroxide and reduce bacteria content in water

IV. Applications

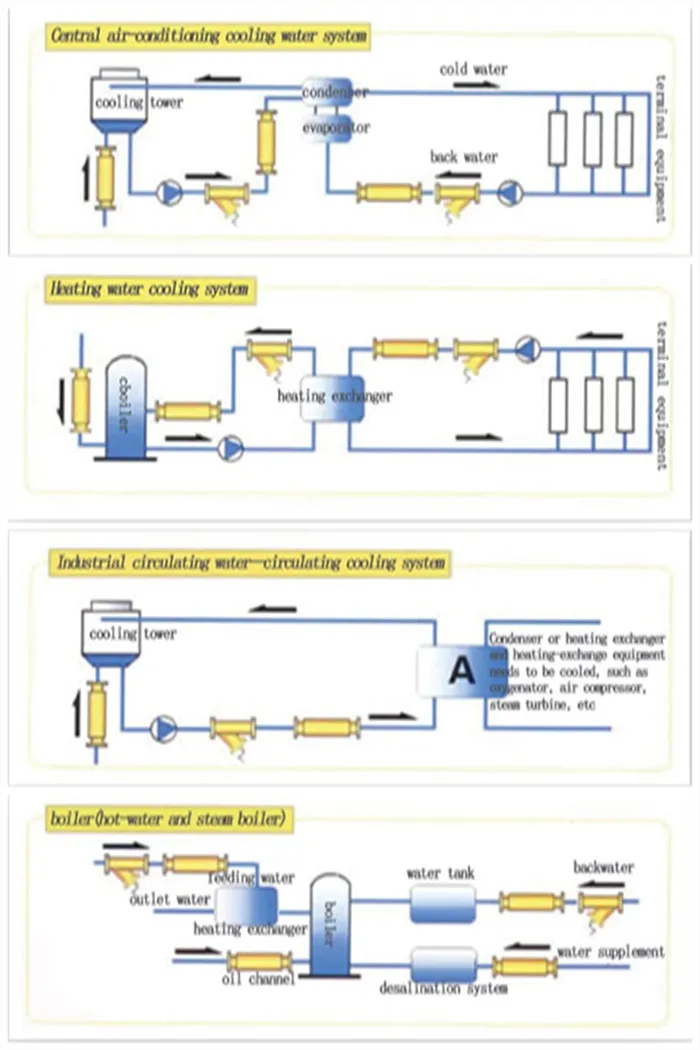

1. Central Air Conditioning System

2. Industrial cooling water system

3. Landscape, swimming pool system

4. Heat exchange system, heating system

5. Production and domestic hot water supply system.

Advantages of magnetic water treatment device in agricultural irrigation

some other details/information got from our testing and previous customer who purchased and operated this magnetic descaling equipment.

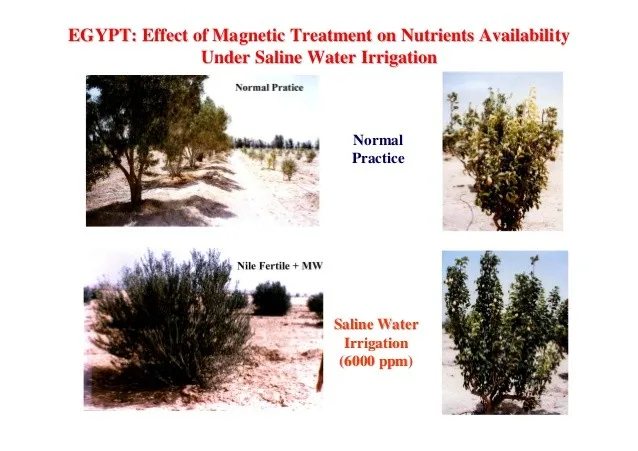

01. As it is hot and dry in North Africa,the water in well or underground will be with higher salt content than normal level,which is not good for growth of plant.

02.as you know, if we want to remove whole salt content in water for human drinking standard,we have to adopt RO system with higher quality and expensive cost. For example, for 1000LPH(1 m3/hour)RO system, it will be much higher cost.most buyer will not accept it. Besides, there is no need to adopt such high level/requirement for agricultural irrigation water if the treated water could reach or get close to normal standard. After all,it is not used for drinking water or pure water.

03.the magnetic descaling equipment with higher magnet power could reduce the salt content in water(NOT remove salt content completely).

04. It is strictly limit or prohibit the chemical dosing for descaling in most countries. it is the strongest descaling effect and lower cost.After all,the more or less chemical residue will be harmful for human beings.

05.The better descaling equipment could be chemical dosing device,but for healthy method, it could be filled with food-grade chemical agent. The best descaling equipment is ion-exchange water softener,but it is with higher cost and require electricity power supplying for working,which will be inconvenient for outdoors operating.

Magnetic water treatment device used in agricultural irrigation water

The magnetic water softener with 10000 to15000 Gauss magnet power is widely used in agricultural irrigation water

The very strong and intense magnetic field within the water magnetier(water magnets) causes the water molecules to change. The magnetic field interferes with the ionic charges of the mineral ions (salts) in the water, which makes them not behave like the same salts any more.

This change results in the water acting “softer”. The minerals contained in the water lose their ability to bond (bond ionically).Calcium and magnesium no longer set like cement, and sodium (and other elements and salts) lose their ability to bind to the soil particles.

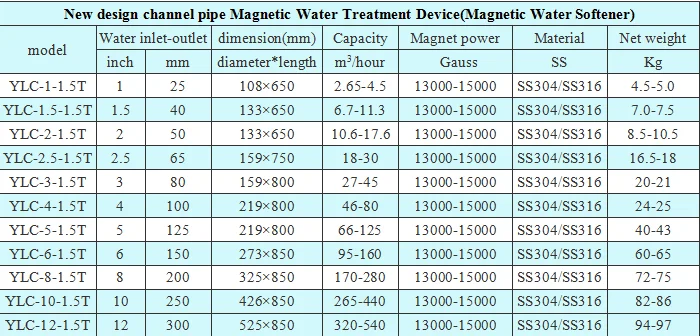

VTechnical parameter

Traditional structure 3000-4000Gauss MWTD

VI.installation instructions

1.Before to install the magnetic water descaling equipment, the magnetic equipment and pipe system should be washed, rust and dust in the intenal pipe should be removed, iron slag and iron powder inside equipment and the pipe also need to be cleaned,and a high filtration rating filter should be installed before the magnetic water descaler section. a valve for sewage outfall should be installed under the equipment.

2.If there is no high filtration rating filter(we suggested it should be ) installed before the magnetic water descaling equipment,the lifespan of magentic water descaler is five to six years .you could also to disassemble the magnetizer to remove ferro magnetic substance which adsorbed in magnetic field according to the practical requirement to prolong the effective lifespan as possible as you can.

3.when it is connected with these water treatment equipment(condenser, heat exchanger, cooling tower,etc),it is better to be vertical installation,which could avoid suspended substance in water precipitate on the magentic water descaler to affect the treatment effect.

4.There should be no water tank or cistern between this magnetic water descaler and the following equipment,which means the water treated by magentic water descaler should flow into the next equipment directly.

Installation and application in industrial water system.

Packages before delivery

-

RUNXIN water softener control valve fully automatic multi-port flow control multi-filtration control valve

-

Small factory water treatment equipment groundwater well water reverse osmosis machinery RO filter mineral water manufacturing machine

-

Reclaimed water recycling system Car wash water recycling system Car wash reclaimed water system Laundry room reclaimed water recycling system

-

High output automatic five gallon filling machine equipment/drinking water filter

-

Water filling station / pure water vending machine for sale

-

Hot Water Softener Ion Exchange Resin for Ion Exchange Resin Tank

-

100 Gallon -- 5000 Gallon PVC Portable Water Storage Tank For Sale

-

Hotsale Medical Ozone Machine Kit Home Clinic Use Therapeutic Medical Ozone Generator

-

Household water purifier system 5/6 stage reverse osmosis system

-

500L/hour 1000L/hour water purifier osmoseurs 5 cassette ro water system Reverse osmosis system Sea water desalination plant