High quality 6 colour flexo printing machine in mexico Plastic Film New 2 Color Flexo Flexographic Printing Printers

-

Supplier: Wenzhou Hero International Trade Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr LOMIO Luo -

Price: $4000.00 /set -

Min. Order: 1 set

Product details

| Marketing Type: | Ordinary Product; | Certification: | CE; |

| Supply Ability: | 50 Set/Sets per Month; | Machinery Test Report: | Provided; |

| Key Selling Points: | Multi Color; | Applicable Industries: | Home Use,Food Shop,Printing Shops,Energy & Mining; |

| Port: | NINGBO,WENZHOU; | Warranty: | 1 Year; |

| Printing Repeat Length: | 380-1600mm; | Condition: | New; |

| After-sales Service Provided: | Engineers available to service machinery overseas,Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; | Max Printing Width: | 1330mm; |

| Video outgoing-inspection: | Provided; | Dimensions(L*W*H): | 21200 x 4600 x 4200mm; |

| Ink: | Waterlnk/UV ink; | Local Service Location: | South Korea,Sri Lanka,Romania,Kyrgyzstan; |

| Place of Origin: | Zhejiang China; | Brand Name: | HERO; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Max.Printing Speed: | 150m/min; |

| Max.Unwinder/Rewinder Diameter: | 1524mm; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; |

| Usage: | Bill Printer,Card Printer,Cloths Printer,Label Printer,Paper Printer,Tube Printer,plastic film; | Max.Web Width: | 1350mm; |

| Core Components: | PLC,Engine; | Gear Size: | 1/8cp; |

| Color & Page: | Multicolor; | Max.Die Cuttinq Width: | 1350mm; |

| Main Motor Power: | 15-18.5Kw; | Weight: | 4050; |

| Packaging Detail: | High quality 6 colour flexo printing machine in mexico Plastic Film New 2 Color Flexo Flexographic Printing Printers; | Automatic Grade: | Automatic; |

| Showroom Location: | Kenya,Argentina,Colombia,Algeria; | Warranty of core components: | 1 Year; |

| Voltage: | 380V; | Plate Type: | flexo; |

| Type: | Flexographic Printer; |

High quality 6 colour flexo printing machine in mexico Plastic Film New 2 Color Flexo Flexographic Printing Printers

Products Description

Brief Introduction

Introduce sensitization resin as flexible printing plate, suitable for printing such packing materials as polyethylene,polyproplene bag,cellophane and roll paper, etc. It is a kind of ideal printing equipment for producing paper packing bag for good, supermarket handbag, vest bag and clothes bag,etc.

Main Features

1. Take it easy, accurate color, long life.

2. Use motors, variable frequency speed control, saving electricity, small running fluctuations.

3. Off printing roll automatic stop the ink-running motor, and up-printing roll automatic start running the ink.

4. Use special diagonal-tooth gear, accurate printing size.

5. Two sets of heating devices, including central heating and constant temperature control system for group control.

6. Low-roller special steel processing, and special process, and plating thickness of 0.1mm protective layer of hard chromium.

7 Alloy roll with hard oxidation, treating by dynamic balance, static balanced.

8 With cold wind bellows, and can effectively prevent produce with ink adhesion after printing

9. Print produce are clear and good arrangement quality.

10. Bearing: NSK, Japan Brand, Germany ASNU aluminum alloy roll

Optional

1.EPC correction system

2.Automatic tension adjustment system

3.Still image (monitor printing status)

4.Friction winding (depending on printing material)

Model | HR6-800 |

Printing Material | BOPP, Polyester, HDPE, PP |

Machine color | 6Color |

Max. Material width | 850mm |

Max. Printing width | 800mm |

Max.printing length | 250-900mm |

Max. Machine speed | 120m/min |

Max. Printing speed | 100m/min (According to material ) |

Register precision | Crosswise:±0.25mm Longitudinal:±0.25mm |

Plate thickness | 2.28mm or 1.7mm (Or customer requirement ) |

Double tap thickness | 0.38mm(3M) |

Machine total power | 40Kw |

Voltage | Voltage 380V, 3 PH, 50 Hz |

The machine color printing width can be customized according to your needs

Details Images

We provide you with a complete plastic product production line

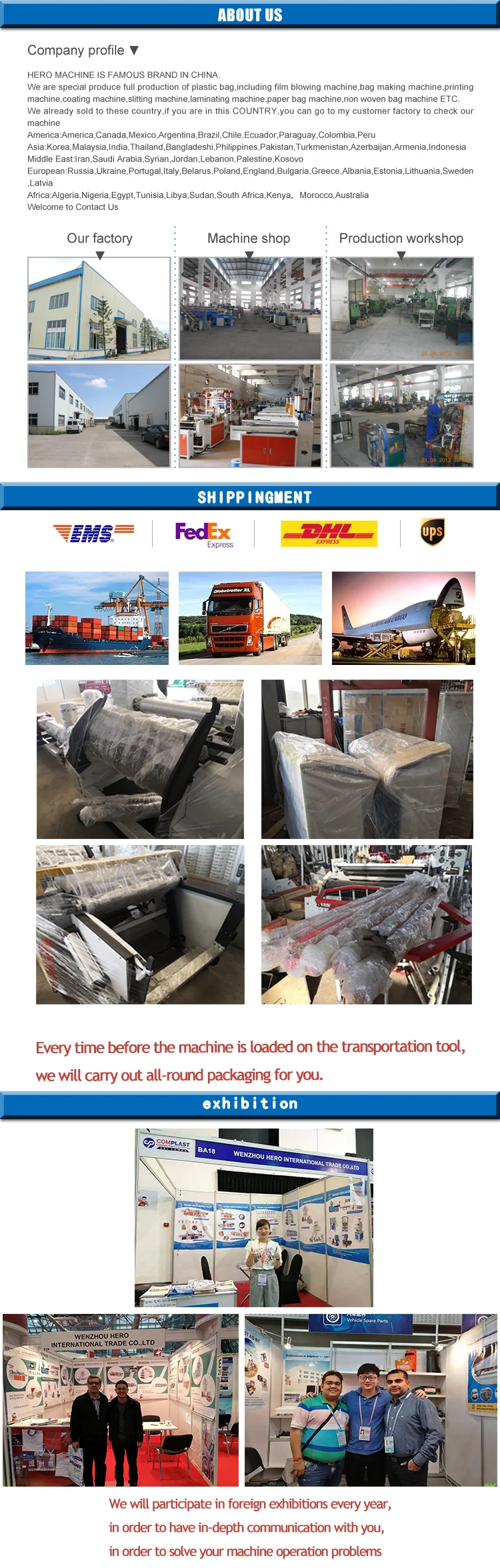

Company Profile

FAQ

Q1:Are you a factory or trading company?

A1: We are established in 1985, a actual factory and manufacturer in the line of printing&package machine for 20 years.

Q2:Where is your factory located? How can I visit there?

A2: Our factory is located in Rui'an City, Zhejiang Province, China, about one hour by air from Shanghai. All our clients, from home or abroad, are warmly welcome to visit us!

Q3: Which industries are widely used in of your machine?

A3: Those are mainly used in making plastic bags and labels in the maket. Examples of stand up pouch, zipper pouch, plastic bag for dialy necessities and food, plastic label for drink bottle, Foil yogurt cup, Medical pouch, laminated film or soft carboard, etc.

Q4: How about the payment term?

A4: For new customer, our payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery.

Q5: What about your main market?

A5: Ourproducts be sold well in 30 provinces and have good reputation in China, also we pay attention on developing the overseas market, such as Europe, Russia, Southeast Asia, Middle and South America, Africa, and other countries.

Q6: How does your factory do regarding quality control?

A6: Quality is the most important principle. GREAT WALL people always attach great importance to quality controlling from the very beginning to the very end. Our factory has passed ISO and CE certification.

Q7:What about warranty and do the engineers available to overseas?

A7: One year warranty. During this period, if the machine has some problems, our engineers can go abroad to fix for you.

Q8:What about the service after sale?

A8: One you have bought our machine, you can call us or email us telling us the machine problems and any questions about the machines. We will reply to you with 12hours and help you to slove the problem.

VIEW MORE

You may like

-

Flexographic Printing Machine Corrugated New High Speed Ci Woven Shopping Bag Flexographic Printing Machine

-

YT-4600 flexographic printing machine flexographic printing machine 6 colors

-

Flexo Label Printing Machine, High Quality Flexo Printing Machine, 8 Color Flexo Printing Machine

-

Online Monochrome Logo Flexo Printing Machine

-

2 Colors Non Woven Film Bag Flexo Printing Machine Plastic Paper Flexo Sachet Printing Machine Machinery

-

Fully automatic flexo printing machine printing machine

-

2 3 4 5 6-color paper cup blank fan-shaped printing punching machine

-

Digital label printing machine ZBRY-480

-

With Dryer Logo Flexographic Printing Machine Automatic Paper Bag Printer 1-5 Colors Non Woven Plastic Bag Printing Machine Printing Machine

-

Single color mini flexo printing machine

Other Products

-

$1000.00 / set

$1000.00 / set -

$4000.00 / set

$4000.00 / set -

LDPE HDPE PE Blown Film Extruder Machine To Make Plastic Bag Film Plastic Film Blowing Machine Price$1000.00 / set

LDPE HDPE PE Blown Film Extruder Machine To Make Plastic Bag Film Plastic Film Blowing Machine Price$1000.00 / set -

$1000.00 / set

$1000.00 / set -

$2000.00 / set

$2000.00 / set -

$1000.00 / set

$1000.00 / set -

$1500.00 / set

$1500.00 / set -

Efficient polypropylene film blowing blow molding machine PE Greenhouse Plastic Film Blowing Machine$2000.00 / set

Efficient polypropylene film blowing blow molding machine PE Greenhouse Plastic Film Blowing Machine$2000.00 / set -

$2000.00 / set

$2000.00 / set -

$3000.00 / set

$3000.00 / set

Related Search

high quality beverage bottle shrink packing machine

high quality electric water pump motor price in pakistan

high quality semi auto printing slotting machine

high qualiti badg print machin suppliers

colours flexo printing machines

corrugated board flexo printer slotter machine in

high quality toilet soap machine

high quality edge banding machine edge bander

high quality tea plucking machine

high quality vacuum aluminium coating machine