Flexo Printing Machine Plate Mounting Machine

-

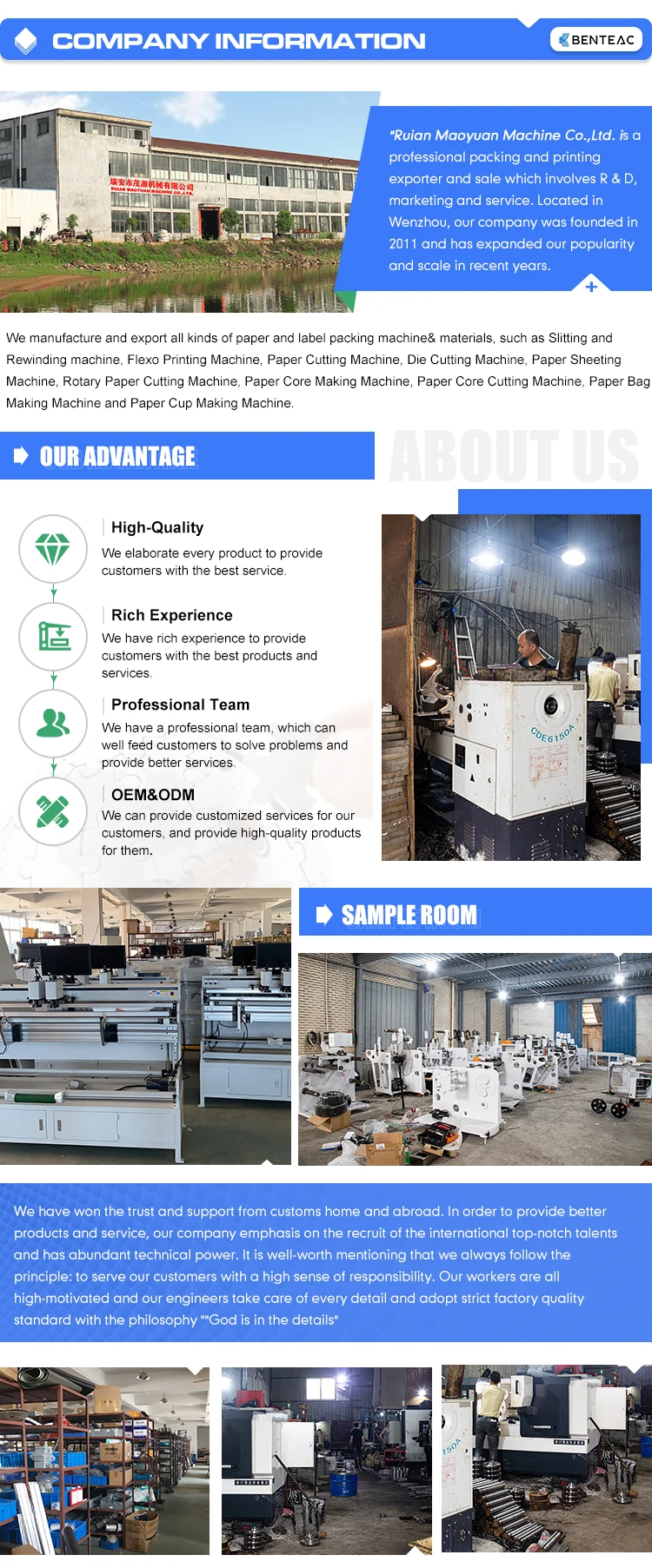

Supplier: Ruian Maoyuan Machine Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr John Yang -

Price: $5000.00 / 1 - 1 sets

$4800.00 / >=2 sets -

Min. Order: 1 set

Product details

| Brand Name: | Gawang; | Usage: | Customer requirement; |

| Dimension(L*W*H): | 1100*600*1000mm; | Effective Width of the Plate: | 330MM; |

| Diameter of the Central Spindle: | 150MM; | Place of Origin: | Zhejiang China; |

| Packaging Detail: | Automatic Digital Flexo Printing Machine Plate Mounting Machine is film wrapping and wooden case.With this machine,we will supply one year guarantee, whole life technical support, a set of tools, a box of vulnerable parts, English Manu, Inverter Manu and Electrical Schematic Diagram.; | Certification: | CE; |

| Package Preview: | ; | Local Service Location: | Pakistan,India,UAE; |

| Automatic Grade: | Automatic; | Marketing Type: | New Product 2019; |

| Supply Ability: | 10 Set/Sets per Month; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Video outgoing-inspection: | Provided; | Maximum Focal Length of the Camera Lens: | 70 Times; |

| Warranty of core components: | 1 Year; | Showroom Location: | Pakistan,India,UAE; |

| Machinery Test Report: | Provided; | Payment Terms: | L/C,T/T; |

| Voltage: | 220V; | Precision of the Plate: | Better than ±0.15MM; |

| Warranty: | 1 Year; | Condition: | New; |

| Key Selling Points: | High-accuracy; | Gear Motor Drive: | Approximate to 300mm/min (Plate Roller); |

| Weight: | 200kg; | Core Components: | Engine,Motor; |

| Applicable Industries: | Manufacturing Plant; | After-sales Service Provided: | Online support,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; |

| Type: | Flexo Printing Machine Plate Mounting Machine,Conventional Plate Processor; | Resolution Ratio of the Camera Lens: | 650 Line; |

| Port: | Ningbo/Shanghai; |

Features:

1. It adopts a precision screw mechanism that can be adjusted up and down, Japan Seiko brand advanced zoom lens, cameras on both

sides, high-definition LCD monitor display. 2. Precise linear guide, the motor drives the ball screw to position left and right.

After aligning the printing plate, the cylinder locks the printing plate to ensure the accuracy of the placement.

3. The camera can be adjusted in all directions, the degree of parallelism can be adjusted, the precision of the placement is

high, and the color registration is accurate.

4. Sleeve-type plate mounting can be carried out.

5. Fast paste version, convenient operation and greatly improved work efficiency.

6. It is suitable for letterpress printing such as flexo printing and resin printing.

sides, high-definition LCD monitor display. 2. Precise linear guide, the motor drives the ball screw to position left and right.

After aligning the printing plate, the cylinder locks the printing plate to ensure the accuracy of the placement.

3. The camera can be adjusted in all directions, the degree of parallelism can be adjusted, the precision of the placement is

high, and the color registration is accurate.

4. Sleeve-type plate mounting can be carried out.

5. Fast paste version, convenient operation and greatly improved work efficiency.

6. It is suitable for letterpress printing such as flexo printing and resin printing.

Model | Cylinder width(mm) | Cylinder Perimeter(mm) | Machine Length(mm) | Machine Width(mm) | Machine Height(mm) | Weight(kg) |

GW-TB-320 | 320 | 800 | 920 | 600 | 1650 | 230 |

GW-TB-650 | 650 | 800 | 1050 | 600 | 1650 | 270 |

GW-TB-1000 | 1000 | 1200 | 1500 | 600 | 1650 | 330 |

GW-TB-1200 | 1200 | 1200 | 1700 | 600 | 1650 | 370 |

GW-TB-1300 | 1300 | 1200 | 1800 | 700 | 1650 | 420 |

GW-TB-1500 | 1500 | 1200 | 2100 | 700 | 1650 | 450 |

GW-TB-1800 | 1800 | 1200 | 2400 | 700 | 1650 | 500 |

Special orders with special size accepted

Best-selling all over the world:

Our products are sold all over the world

and have accumulated an excellent

reputation among our customers.

Elite team:

The team has strong technology

and the employees are experienced

to mature. It is your ideal partner

and strong backing.

Efficient service:

Based on the wishes and priority

standards of customers, we are

anxious to what customers need,

and your satisfaction is our pursuit.

Serious and responsible:

The testing equipment is fully equipped

for you to save worry and effort for us,

please relax and leave it to us.

Features:

1. The lens is 150mm away from the printing roller for easy operation.

2. The left and right cameras magnify the crosshairs on the board by 50 times and display them on the monitor.

3. The display shows double crosshairs as a reference for placement, and the vertical lines of the crosshairs can be moved left and right to facilitate fine adjustment.

4. The printing roller adopts the cylinder locking position (left-right direction and circumferential direction), the operation is more convenient.

5. After the version is pasted, the printing roller can be rotated (fixed in the left and right direction) to check whether the positions of several sets of crosshairs are correct.

6. The color accuracy is more precise, the error is about 0.01MM.

model | Max.Roller Width(mm) | Max.perameter(mm) | Machine Length(mm) | Machine Width(mm) | Machine Height(mm) | Weight(kg) |

GW-TB-2000 | 2000 | 2000 | 3150 | 1050 | 1850 | 650 |

Special orders with special size accepted

1. 1year guarantee, 1Year spare parts packing together with the machine,the whole life technician support.

4.Operation Manual, Operation or repair Video,

5.24-hours Email technical support, we will do our best to help the clients solve any question or problems.

6.Available to send our engineer to clients factory, to install the machines, train the workers, repair the machines.

2. With professional engineers, you can go to the world for on-site mechanical maintenance

3. Have a large number of overseas service sites to meet all kinds of on-site viewing

4.Operation Manual, Operation or repair Video,

5.24-hours Email technical support, we will do our best to help the clients solve any question or problems.

6.Available to send our engineer to clients factory, to install the machines, train the workers, repair the machines.

VIEW MORE

You may like

-

Amsky U864 UV CTCP V3 V4 Laser Diode Spare Parts

-

Photopolymer flexo resin plate washing machine for offset printing Flexographic rubber plate making machine

-

Solvent-based flexo plate-setter Offset plate-setter

-

LED machine for displaying mini polymer plates

-

New Kodak ctp machine price in 2022

-

Hot sale heating plate 70x100 80*100cm double large format manual heat press sublimation shirt printing machine

-

CTP Goods Manufacturer Wholesale New UV CTP 405nm 200mW Laser Diode v1 v3 v4 v6 v8 from China

-

SCREEN 8000II 8600E 8600SL 8600MII 4600N 8900 Used CTP Machine

-

Second-hand computer plate-making machine CTP CTCP machine

-

Photosensitive resin digital flexo plate making machine flexo plate making machine

Other Products

-

$15000.00 / set

$15000.00 / set -

$6800.00 / set

$6800.00 / set -

$25000.00 / set

$25000.00 / set -

$11000.00 / set

$11000.00 / set -

$10000.00 / set

$10000.00 / set -

$6800.00 / set

$6800.00 / set

Related Search

ci flexo printing machine

corrugated box flexo printing machine

cardboard flexo printing machine

corrug box flexo print machin suppliers

corrug flexo print machin suppliers

paper water ink flexo printing machine

ry 320 label flexo printing machine

flexo printing machines 5 colour for carton

colours flexo printing machines

talsen 320 label flexo printing machine