4KW movable electric or pneumatic lifting high shear mixer cosmetic cream homogenizing emulsifying machine

-

Supplier: Guangzhou Yeto Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Coco Ruan -

Price: $1500.00 /unit -

Min. Order: 1 unit

| lifting Type: | Pneumatic / electric; | Packaging Detail: | penumatic lifting homogenizer With plywood case packing,also can be customized.; |

| Condition: | New; | Application: | Medicine,food,chemical Processing,Viscous Fluid; |

| Machinery Test Report: | Provided; | Application scope: | Chemical Cosmetic,Pharmacy ,food; |

| Machine Type: | high shear mixer homogenizer; | Function: | High Shear mixer; |

| Package Preview: | ; | Barrel Volume (L): | 300; |

| Mixer Type: | Homogenizer; | Applicable Industries: | Manufacturing Plant,Food & Beverage Factory,cosmetic factory; |

| Dimension(L*W*H): | 1.0*1.0*2.1m; | Material Processed: | Plastics,Chemicals,Food,Medicine; |

| Material: | SUS304; | Usage: | Cosmetic Industry; |

| Range of Spindle Speed(r.p.m): | 1 - 2880 r.p.m; | Place of Origin: | Guangdong, China; |

| Weight (KG): | 380 KG; | Core Components: | Motor; |

| Voltage: | 380V/50Hz; | Warranty: | 1 Year; |

| Supply Ability: | 30 Units per Month penumatic lifting homogenizer; | Marketing Type: | Ordinary Product; |

| Max. Loading Capacity: | 100-300L; | Brand Name: | Yeto; |

| Warranty of core components: | 1 Year; | Stirrer type: | High Speed Homogenizer; |

| Payment Terms: | Western Union,D/P,D/A,T/T,MoneyGram,penumatic lifting homogenizer; | Material connect material: | SUS304/316L; |

| Product Type: | Cosmetic; | Max. Loading Volume (L): | 300 L; |

| Power (kW): | 4 kW; | Port: | Guangzhou port; |

| Additional Capabilities: | Milling; | Showroom Location: | None; |

| Video outgoing-inspection: | Provided; | Key Selling Points: | Easy to Operate; |

| material of frame: | stainless steel or iron; |

4KW movable electric or pneumatic lifting high shear mixer cosmetic cream homogenizing emulsifying machine

Pneumatic lifting high shear homogenizer(left)+ high speed disperser(right)

Application:

YETO-pneumatic lifting homogenizer is special for a number of different viscosity liquid stirred at high speed, homogenizering, dissolving, mixing efficient equipment, material movement at different speeds through a special shear impeller rotation, so that rapid dispersion of aggregates , and then to dissolve, emulsify, homogeneous mixing, high quality and efficiency of fast, wide range of applications.

Structure:

This series of machines are: support frame, motor, homogenizing head, cylinder, electrical control systems and control devices. Compact, easy to install, clean and generous appearance.

Homogeneous pinion lift off with pneumatic type, up off the smooth and flexible. Homogeneous gear shaft and main parts are all made of stainless steel, wear resistance, corrosion resistance, excellent quality and long service life, smooth operation, low noise, any rise in the operation down, according to material viscosity, speed arbitrary regulation to prevent the material flying, dispersion impeller for a variety of materials.

Installation method is flexible to adapt to a variety of venues operation is extremely simple, easy maintenance, strong and beautiful body. Advanced features, easy to operate, safe facilities will bring your work pleasant.

Parameter:

| Capacity | 50-100L |

| Power | 4kw 380v 50Hz |

| material connect material | SUS304 |

| Material of frame | iron or stainless steel |

| Motor |

Siemens motor |

|

Inverter |

Delta |

|

Air pressure |

4-8 kg/cm2 |

|

Homogenizer speed |

0-2880r/min |

|

The height of homogenizer can be lifted |

1000mm |

Control panel

Lifting up and down,speed adjutment all can be operated on it.

Motor

According to different output requirements, there are multiple models with different motor powers to selected. Such as 2.2kw,4kw,5.5kw,7.5kw etcs

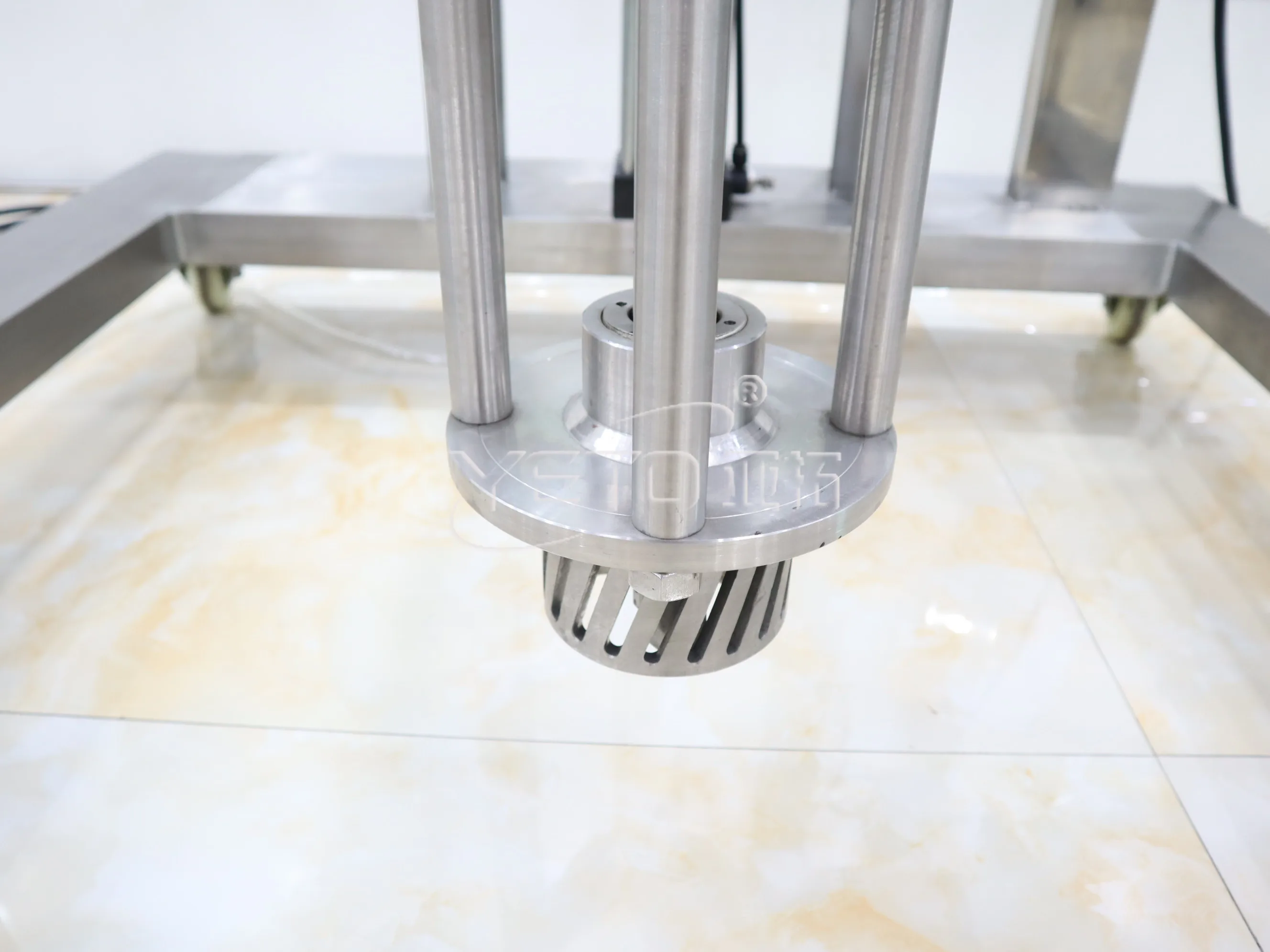

High shear emulsifying head

The speed adjustable from 0 to 2880rpm.

Contact part material can choose SUS304 or SUS316L.

Pneumatic lifting mixer

Electric lifting homogenizer

Remark: 1.You can use your own storage tank,just please tell us your tank size before order.Or we can provide storage tank separately.

2.If you have special requirements for the material , stirring paddle ,mixing speed or dimension,please contact us freely.

1. What about your factory?

One of our factory is located in Guangzhou and another one is in Jiangsu province. We have more than 100 workers in our factory ,over 20 years experience on cosmetic machinery making and more 15 years experience for installing overseas.

2.What you can do for us if the machine is out of your catalogue?

As a professional machinery manufacturer for more than 20 years,we have skilled OEM technique.

3.What do we do if we encounter problem about the machine ?

Showing us the picture or video of the problem. If the problem can be solved by your workers, we will send you solution by video or pictures. If the problem out of your control, our engineer will be sent to your factory (customer will pay the fee during the trip).

4. What about after sale service?

We provide two years warranty period for large equipment, such as hydraulic homogenizer ,vacuum emulsifying mixer etc. One year for small filling machines, such as semi-automatic labeling machine series.

We provide wearing parts(not caused by improper operating) for free within the warranty period(except delivery fee).

5.How about warranty and spare parts?

We provide 1-3 years warranty and enough spare parts for the machine,and most of the parts can be found in local market also,also you can buy from us if all the parts that we provided are finished.

6 How to finish installing?

Our engineer can be sent to your country. but customer should pay the air tickets. besides, customer should arrange the accommodation for them during the trip.

7. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise that our wooden packaging is strong enough and safety for long delivery .

-

Electric Hand Mixer 6 Speed Adjustable Paint Mixer Cement Putty

-

Daily chemical washing powder production line/washing powder making machine/washing powder equipment

-

500L low speed paint mixer high speed food liquid dispensing mixing equipment with mixing tank 316 stainless steel 5.5kw

-

1000 Liters Liquid Soap, Liquid Fertilizer Tank Mixer

-

Mobile Industrial 1000 Liters Emulsion Emulsion Agitator Steam Jacketed Mixing Tank with Agitator and Agitator

-

Electric Handheld Cement Mixer Dp-M207A Electric Paint Mixer

-

Stainless steel disc high quality thickened dispersing blade mixer 50mm to 600mm dispersing disc for dispersing paint mixer

-

WHAMX 2600W 6 Speed High Power Aircraft Drilling Cement Paint Mixer

-

China New Product FMF6-24 Industrial Epoxy Resin Disposable Static Mixer Nozzle

-

High Power Cement Putty Powder Mixer 2100W Professional Electric Paint Mixer

Other Products

-

$1250.00 / set

$1250.00 / set -

$1800.00 / set

$1800.00 / set -

$1700.00 / set

$1700.00 / set -

$5000.00 / set

$5000.00 / set