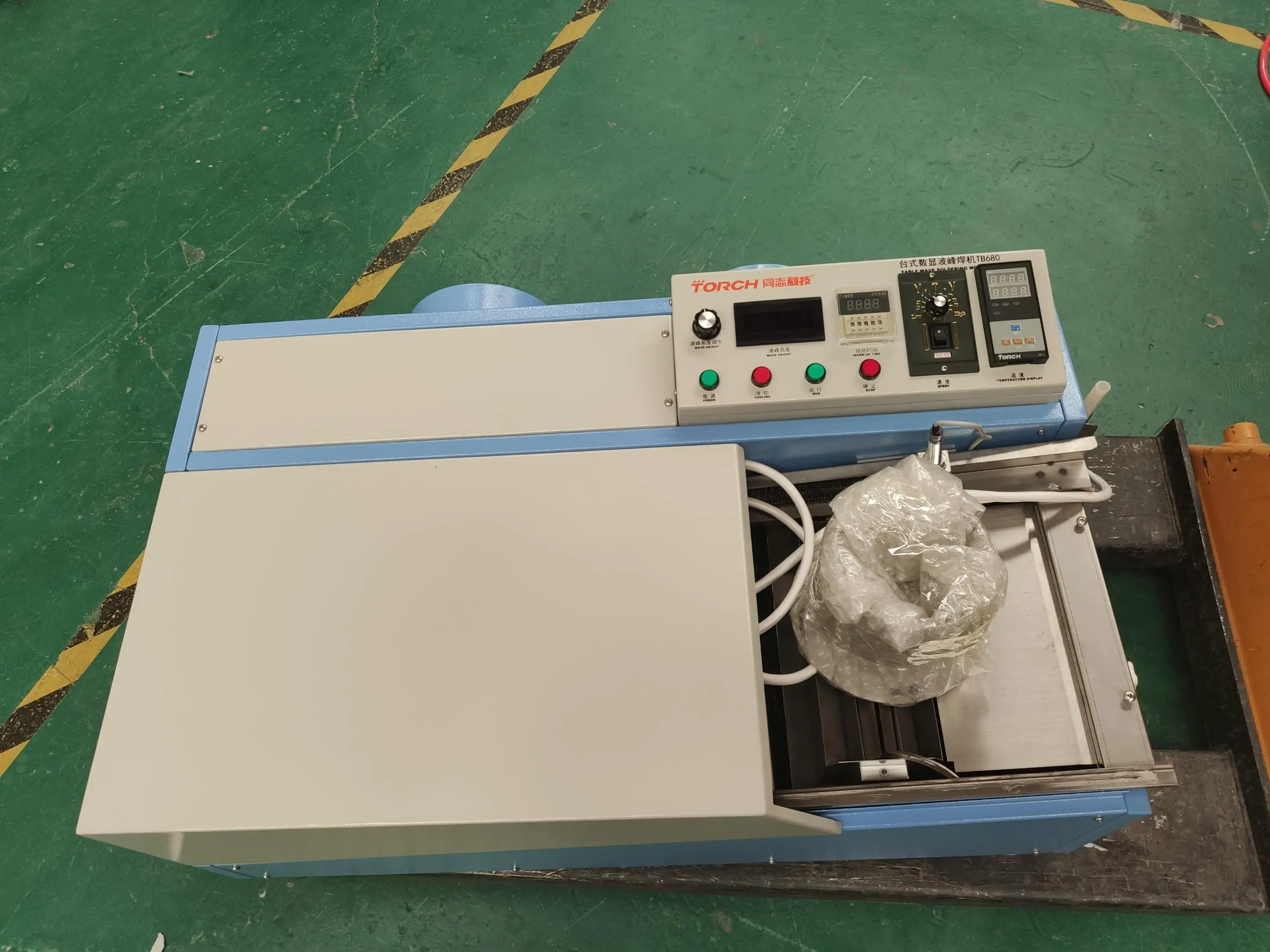

Small size desktop wave soldering machine TB680

-

Supplier: Beijing Torch SMT Incorporated Company -

Region: Beijing, China -

Contact: Mr Richard zhao -

Price: $3200.00 / 1 - 1 sets

$3000.00 / 2 - 4 sets

$2900.00 / >=5 sets -

Min. Order: 1 set

| Machinery Test Report: | Provided; | Single gross weight: | 82.000 KG; |

| Max PCB size: | 200*270mm; | Packaging Detail: | wooden package , Gross weight: 82kg Dimension: 100*64*60cm; |

| Video outgoing-inspection: | Provided; | Warranty: | 1 year; |

| Single package size: | 99X63X51 cm; | Solder pot capacity: | 37kg; |

| Spray work mode: | froth; | Power: | 3KW; |

| Item: | mini wave soldering machine; | Dimension(L*W*H): | 84*54*38cm; |

| Core Components: | Motor,Gear; | Local Service Location: | None; |

| Voltage: | 220V; | Melt time: | 60min; |

| Weight: | 65KG; | Showroom Location: | None; |

| Certification: | CE; | Warranty of core components: | 1 Year; |

| Brand Name: | TORCH; | Selling Units: | Single item; |

| Temperature range: | 200~300℃; | Wave height adjust range: | 5~ 10mm; |

| After Warranty Service: | Video technical support,Online support,Field maintenance and repair service; | Marketing Type: | Hot Product 2019; |

| Place of Origin: | Beijing, China; | Condition: | New; |

| Applicable Industries: | Manufacturing Plant,SMT; |

Small size desktop wave soldering machine TB680

Beijing TORCH Desk wave soldering machine TB680 has been developed by Torch, It is the first equipment in small type wave soldering field. TB680 is suitable for research center, war industry, middle- and small-sized corporation, small private corporation and other electronic production companies. It is a desk-type, taking up small room, with multi-functions, energy-saving and high efficiency. The operation is easy and especially suitable for small and middle batch production.

| Name | Desktop wave soldering machine TB680 |

| Max power | 3KW |

| PCB size | 200X270mm (max) |

| Tin pot capacity | 37Kg |

| Temperature range | 200-300°C LED display |

| Preheating temperature | 70-90°C |

| Height of wave crest | 5-12mm |

| Melting time | 80min |

| Flux spray | froth |

| Power supply | 220V±1%V AC single phase 50Hz (please connect power to the ground) |

| transmission speed | 0.5-3m/min |

| Dimension | 850X600X330mm |

| G./N. weight | 65/82KG |

Function

There are 6 parts: flux, preheating, soldering, electrical controlling, exhaust unit and convection unit.

1. Flux

Flux parts are made of air pump, air tube, pin valve, filter, froth tube and flux box.

There is flux belt on the froth tube, PCB whose side has chips is on the top and touch flux, the side will has flux film.

2. Preheating

It is made by melt board with resistor to provide heat for PCB.

3. Soldering

It is made by tin pot, heating board, wave pump and tin.

|

1 tin pot 2 clapboard 3 nozzle 4 regulator 5 wave pump 6 channel |

Soldering

Figure 3: The solder will be divided into upper and lower levels by clapboard, the lower for the high-pressure layer, the upper layer for the low-pressure layer, liquid solder will be into high pressure layer driven by wave pump, the solder in the high pressure layer rotate and then pass regulator, it will overflow from the nozzle, the wave crest form and then fall into low pressure layer because of gravity

4 electrical controlling

With modular structure, transmission speed, solder temperature, preheating time and others can be adjusted and controlled. Working principle is shown in Figure 4.

Figure 4 electrical controlling

5. Exhaust unit

It is made of cover, air fan, air cover and air tube. All exhaust generated in soldering will be eliminated.

6. Convection unit

It is made of chain, rail, drive and pallet. PCB will be sent in flux unit, preheating unit and soldering unit by convection unit.

TB780D wave soldering machine TB880C wave soldering machine

TB980C wave soldering machine MINI type TB680

TORCH CO,. Ltd was found in 2001, focus on R&D and production of SMT equipment. It has been the leader on SMT industry in domestic. TORCH Co,. Ltd keeps the faith “Intelligent production, Intelligently create future” and developed many SMT equipment by itself. At present, TORCH C., Ltd owns more than 100 patents, brands and software rights. Moreover, it also passed ISO9001, CE and other certifications. Strategic objectives: to optimize the technology based on keeping the existing mature development, production, sales and service mode and continue to consolidate and strengthen its advantage position in the SMT electronic equipment field, with existing key products as the center, to expand the supply chain has become the Internet + intelligent manufacturing electronic factory of 2025 and the overall solution project of industrial upgrading optimized brand.

-

PCB board packaging vacuum packaging machine is simple to operate and simple to maintain.

-

Multifunctional Universal LED Bulb Assembly Equipment Fully Automatic LED Bulb Making Machine

-

Customized LCD Machine Accessories Glass Rod Quartz Rod

-

Magnetic powder brake

-

SE Series Arise actuators with various thrusts and shocks

-

Mobile Phone Jack Vacuum Coating Back Cover Film Envelope Machine for iPhone SAMSUNG Huawei Honor

-

Mobile phone hydrophobic nano liquid spraying machine

-

Pcb Drill Routing Cnc Machine Pcb Separator Cutting Machine Split Circuit Board Machine

-

85 inch Lcd Led Laptop Laser Screen Panel Repair Machine Laser Welding Solder Repair Machinery Bright Line Laser Repair

-

LED bulb machine light source board glue machine LED bulb machine electrical equipment