Full Automatic Shrink Sleeve Cups / Bottle Labeling Machine for PVC Neck Sleeve Labeling Unit Machinery Capacity / PET Label

-

Supplier: Zhangjiagang City Fillpack Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Alice Gu -

Price: $10000.00 /set -

Min. Order: 1 set

| Applicable Industries: | Food & Beverage Factory,Food & Beverage Shops; | Labeling speed: | 150 bottle/min; 250 bottle/min; |

| Weight: | 200 KG; | Place of Origin: | Jiangsu, China; |

| Applicable Diameter of Bottle Body: | 28mm-125mm; | Marketing Type: | New Product 2021; |

| Packaging Detail: | 1) The special packaging box is according to the immunity standard in China,it suits for long-distance transport, damp proof, rustproof, land way and seaway. 2) Transportation ways: Ocean transportation; | Selling Units: | Single item; |

| Local Service Location: | Egypt,Canada,Turkey,United Kingdom,United States,Italy,France,Germany,Viet Nam,Philippines,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,India,Mexico,Russia,Spain,Thailand,Malaysia,Australia,Morocco,Kenya,Argentina,South Korea,Chile,UAE,Colombia,Algeria,Sri Lanka,Romania,Bangladesh,South Africa,Kazakhstan,Ukraine,Kyrgyzstan,Nigeria,Uzbekistan,Tajikistan; | Driven Type: | Electric; |

| Packaging Type: | Bottles; | Bottle separation: | Screw rod bottle separation; |

| Core Components: | PLC,Motor,Engine,Pump; | Type: | LABELING MACHINE; |

| Machinery Capacity: | Neck sleeve labeling unit; | Kinds: | Single head or double head; |

| Dimension(L*W*H): | L1800*W850*H2000; L3000*W850*H2000; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Warranty of core components: | 1 Year; | Showroom Location: | Egypt,Canada,Turkey,United Kingdom,United States,Italy,France,Germany,Viet Nam,Philippines,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,India,Mexico,Russia,Spain,Thailand,Morocco,Kenya,Argentina,South Korea,Chile,UAE,Colombia,Algeria,Sri Lanka,Romania,Bangladesh,South Africa,Kazakhstan,Ukraine,Kyrgyzstan,Nigeria,Uzbekistan,Tajikistan,Malaysia,Australia; |

| Single gross weight: | 68.000 KG; | Thickness of label: | 0.035mm-0.045mm; |

| Application: | Beverage,Food; | Condition: | New; |

| Key Selling Points: | Easy to Operate; | Certification: | CE ISO; |

| After-sales Service Provided: | Engineers available to service machinery overseas,Online support,Video technical support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service; | Applicable Thickness of Label: | 30mm-250mm; |

| Video outgoing-inspection: | Provided; | Input Voltage: | 380/220VAC; |

| Function: | Sleeve Labeling; | Packaging Material: | Glass,Plastic; |

| Single package size: | 24X25X24 cm; | Brand Name: | Fillpack; |

| Warranty: | 1 Year; | Machinery Test Report: | Provided; |

| Voltage: | 220V; | Automatic Grade: | Automatic; |

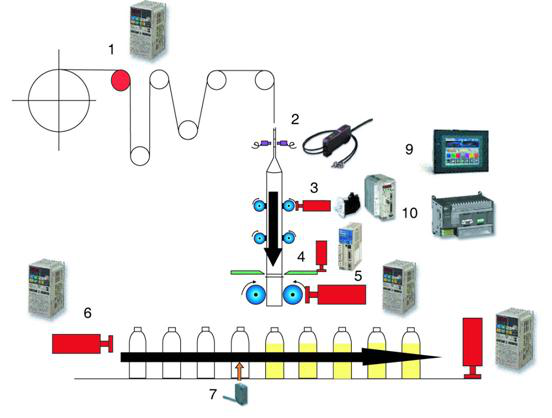

Working pricinple of sleeve labeling machine

Shrink labeling is a two-step process. First, a heat-shrinkable plastic sleeve is dropped over a bottle as it moves by on a conveyor. Second, the sleeved bottle is conveyed through a heat tunnel that shrinks the label to a snug wrinkle-free fit. A shrink tunnel must subject the bottle to the correct amount of heat for the right length of time.

It is a high automatic packing machine. Just one person handles, easy operation.

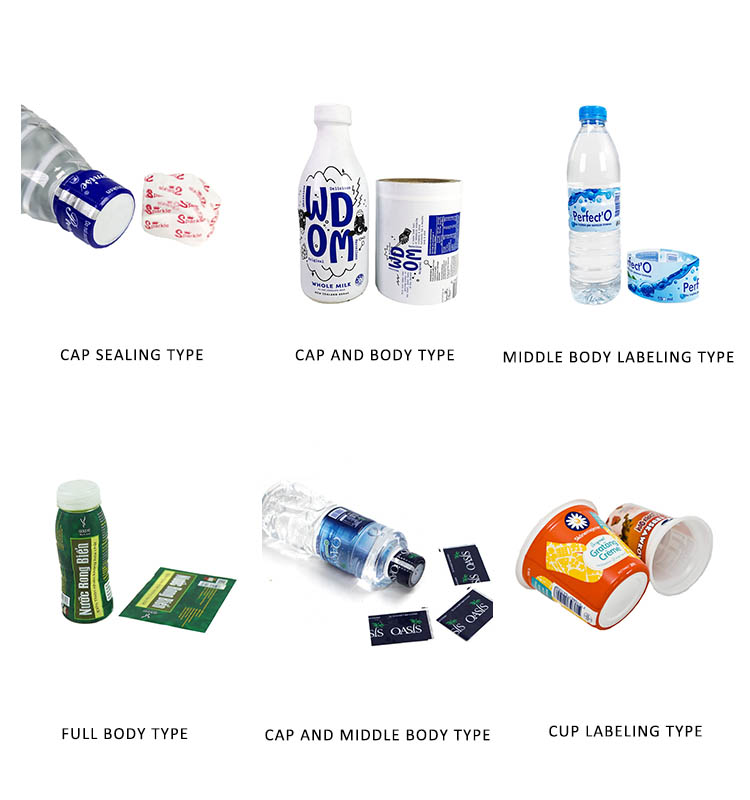

Application

Model | TB-150 (Single head) | TB-250 (Single head) | TB-150-2 (Doubel head) | TB-250-2 (Double head) | |||

Capacity | 150BPH | 250BPH | 150-300BPH | 250-500BPH | |||

Diameter of bottle body | ∮28mm-∮125mm | ||||||

Length of label | 30mm-250mm | ||||||

Thickness of label: | 0.035mm-0.045mm | ||||||

Material of label | PVC、 PET、 OPS | ||||||

Applicator size: | L2000MM*W850MM*H2000MM | L4000MM*W850MM*H2100MM | |||||

1. The machine is packed by wooden case.

2. The delivery date of sleeve labeling machine is within 25 working days after payment.

3L / 5L / 10L mineral water plastic bottle 2 in 1 filling equipment / plant / machine / system / line

mineral water filling machine

bucket / barrel / gallon bottle water washing filling capping equipment / plant / machine / system / line

Vacuum system and blanced tank for bottle beverage producing device with low price

ZhangJiaGang City FILL-PACK Machinery Co.,Ltd. is loacated in Zhangjiagang city which is famous for beverage machinery producer collection. Intergrated the industry advantange and its own development in R&D, production, sales, after sales service, FILL-PACK is ready to serve more and more customers with our full range products and satified service.

FILL-PACK product is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

We are the supplier who can design and manufacture for all kinds beverage production plant(pure drinking water, mineral water, carbonated drinks, juice, tea and beer, etc.)

Customer's service:

1. FILL-PACK company can provide turn-key project for you, only you have any idea to start beverage factory plant.

2. FILL-PACK company have professional design team, our engineer can draw bottle samples and flow chart ofworkshop for you .

3. FILL-PACK company give you the best quotation for all kinds of beverage production, only you can tell me whichkind of drink you want to product, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass,etc

After service:

1. We send the engineers to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the machine:

a. Machine layout

b. Electricity diagram

c. Machine certificate

d. General manual book/maintenance book

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.

Major in International business from XiaMen University ,15 years’ experience in foreign trade,10 years'experience in filling-packing machinery

Whatsapp/Wechat: +8615862615333

E-mail: admin@fillpackmachine. com

Major in engineering,3 years'filling packing machine experience

Whatsapp/Wechat: +8617372553512

E-mail: sales3@fillpackmachine. com

4 years' foreign trade experience

Whatsapp/Wechat: +8617372553526

E-mail: sales6@fillpackmachine.com

3 years experience in mechanical foreign trade, serving every customer with my heart.

Whatsapp/Wechat: +8617372553513

E-mail: sales4@fillpackmachine.com

8 years experience in foreign trade, work seriously, serve customers positively and enthusiastically.

Whatsapp/Wechat: +8617372553517

E-mail: sales7@fillpackmachine.com

E-mail:sales5@fillpackmachine.com

-

LT-600 Car Detergent Liquid Soap Motor Oil Double Sided Self Adhesive Sticker Labeling Machine for Flat Square Bottles

-

LT-330T fully automatic horizontal tube labeling automatic crayon plastic round bottle low temperature bottle labeling machine

-

Semi-automatic square bottle flat carton labeling machine

-

Gainjoys Automatic Labeling Machine Water Bottle Labeling Machine Water Bottle Labeling Machine

-

Semi-automatic Hand Wash Bottle 60ml Sticker Labeling Machine With Date Printing

-

Economical simple manual round bottle labeling machine (manual round bottle labeling machine, labeling machine)

-

MT-30 manual mineral water plastic round bottle labeling machine round bottle self-adhesive label packaging machine

-

Shenglong SL-150 Box Plastic Bag Flat Labeling Machine

-

ZONESUN small desktop semi-automatic spirits tin can wide-mouth bottle round bottle self-adhesive labeling machine

-

Special 1150D Electric Automatic Self-adhesive Label Dispenser

Other Products

-

$2500.00 / set

$2500.00 / set -

$11000.00 / set

$11000.00 / set -

$3000.00 / set

$3000.00 / set -

$11000.00 / set

$11000.00 / set -

$2000.00 / set

$2000.00 / set