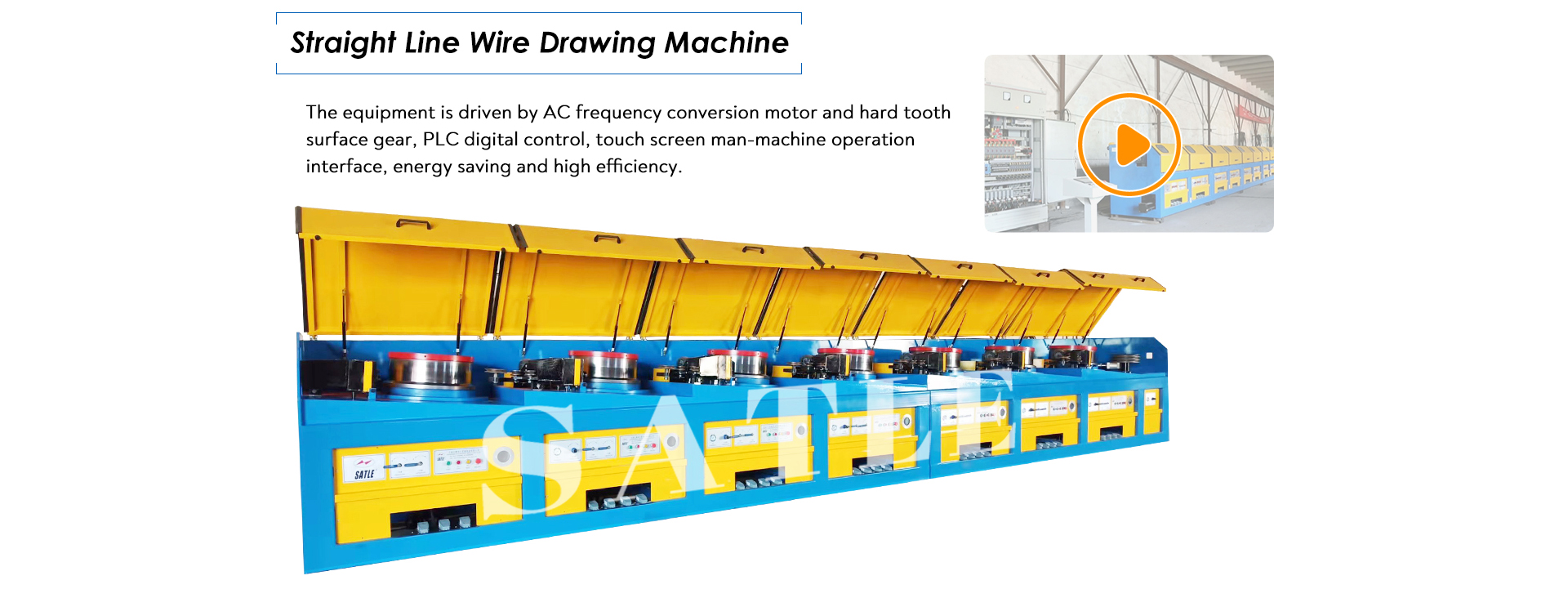

Fully automatic high-speed carbon steel wire drawing machine

-

Supplier: Shijiazhuang Satle Machinery Manufacture Co., Ltd. -

Region: Hebei, China -

Contact: Mr Yongjun Du -

Price: $5800.00 /set -

Min. Order: 1 set

| Warranty: | 1 year | Inlet diameter: | 6.5mm |

| type: | LZ linear wire drawing machine | winch: | 550mm/620mm/700mm/etc |

| Voltage: | 380V upon request | weight: | 1500 |

| Video external inspection: | if | quality: | high standard |

| After-sales service provided: | Video technical support | Outlet diameter: | 2.0mm |

| usage: | brushed metal | Health status: | new |

| Main selling point: | high productivity | Core Components Warranty: | 1 year |

| Supply capacity: | 200 sets per year | motor: | Inverter motor |

| Drawing Materials: | Iron wire, carbon steel wire, stainless steel wire, copper wire, etc. | Showroom location: | not any |

| Dimensions (L*W*H): | 1.3m*1.8m*1.3m | life: | durable |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Winch Warranty: | 1 year |

| Packaging Preview: | brand: | SATLE | |

| Mechanical test report: | if | Core components: | Gearbox, motor, PLC, inverter |

| strength: | 22KW/30KW | year: | 2022 |

| port: | Tianjin harbor | Packaging Details: | Waterproof plastic film or as required |

| Applicable industries: | Building Materials Store, Manufacturing Plant, Construction Engineering, Energy & Mining, Machinery, Hardware | place of origin; place of origin: | Other countries |

| speed: | 12m/s-18m/s | Marketing Type: | normal product |

Fully automatic high-speed carbon steel wire drawing machine

|

Model |

LZ400 |

LZ550 |

LZ700 |

|

|

Incoming wire diameter |

mm |

3.2 |

6.5 |

8 |

|

Outlet diameter |

mm |

0.8 |

2.0 |

5.4 |

|

Number of traction winches |

8 |

9 |

4 |

|

|

motor |

Inverter motor |

Inverter motor |

Inverter motor |

|

|

single power supply |

kilowatt |

11 |

twenty two |

twenty two |

|

Maximum speed |

Miss |

12 |

12 |

10 |

|

winch diameter |

mm |

400 |

550 |

700 |

|

winch material |

Steel Coated Tungsten Carbide |

Steel Coated Tungsten Carbide |

Steel Coated Tungsten Carbide |

|

|

winch warranty |

moon |

twenty four |

twenty four |

twenty four |

|

Main steel plate thickness |

mm |

16 |

16 |

16 |

|

Warranty |

moon |

12 |

12 |

12 |

|

drive mode |

reduction gear |

reduction gear |

reduction gear |

|

|

Control System |

programmable logic controller |

programmable logic controller |

programmable logic controller |

|

|

programmable logic controller |

Siemens |

Siemens |

Siemens |

|

|

Operation |

touch screen |

touch screen |

touch screen |

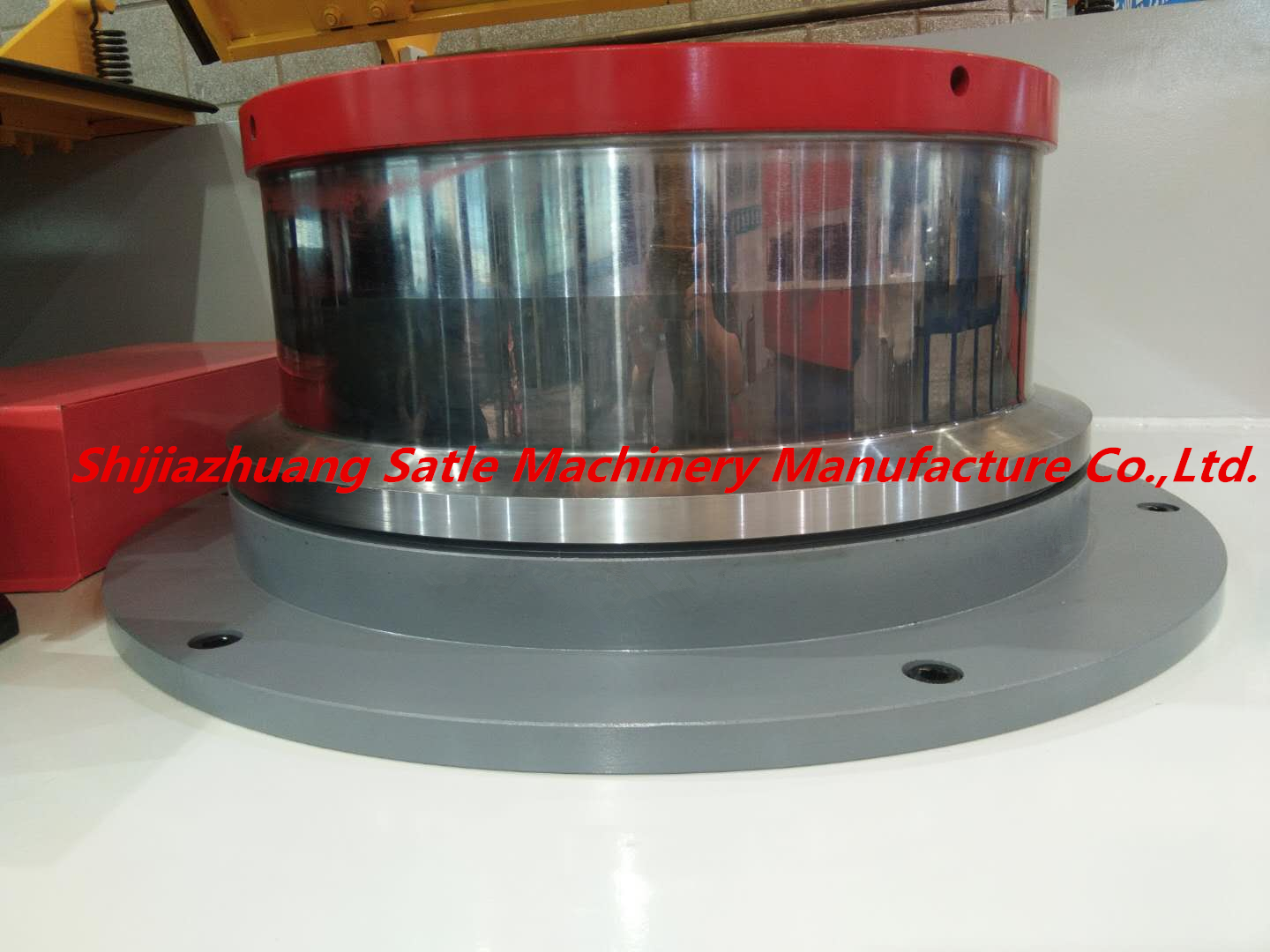

winch structure

The material is ZG45 cast steel billet, HB250 after quenching and tempering. Dig 5mm deep on the working surface of the winch, then melt tungsten, cobalt carbide, and surfacing. After rough turning, fine turning, grinding and polishing, the surface roughness can reach 0.08μm, the height of the hardened layer is 300mm, the depth is more than 3mm, and the HRC is 58-62.

winch cooling

A spiral water jacket is fixed on the main shaft of the winch, and the water wheel is below it. The winch is installed on the main shaft, and the lower part of the water jacket and the inner wall of the winch form a 10-15mm water storage. The circulating cooling water flows from the upper water jacket to the inner wall of the winch, and the water tank is filled with cooling water to fully cool the winding wire. When the winch rotates, the spiral groove keeps the cooling water rising, and then flows down along the winch wall and is discharged through the upper outlet, forming a good circulating water cooling.

Drawing die

Drawing dies, all reels except the finished reels are tilted about 8° to keep the maximum amount of plot line and wire oriented straight on the spool. The adjustment roller adopts anti-pull wire to reduce the pulling force of the die.

photo:

Certificate:

Certificate:

After-sale service:

The whole machine is guaranteed for one year.

Winch for two years.

Low cost of continued maintenance when the warranty expires.

Free training on how to install the machine, how to use the machine.

Engineers can repair machinery overseas.

-

Annealed wire high-speed linear drawing machine, galvanized wire winding machine

-

Monoblock drawing machine for steel bar drawing

-

wet drawing machine

-

Automatic Sheet Metal Polishing Deburring Machine Wide Band Sander For Cutting And Stamping Parts

-

Fire extinguisher barrel deep drawing hydraulic press

-

Cold Rolling Equipment Manufacture 3 Ribbed Steel Bar Machine

-

Small wire drawing machine for making copper wire

-

3 drum wire drawing machine / wire drawing machine

-

Low carbon steel straight wire drawing machine for wire binding

-

0.7mm-0.13mm kitchen Baibao wire drawing machine, stainless steel wire drawing machine

Other Products

-

$6000.00 / set

$6000.00 / set -

$6000.00 / set

$6000.00 / set -

$2000.00 / set

$2000.00 / set -

$4999.00 - $5000.00 / set

$4999.00 - $5000.00 / set -

$4000.00 / set

$4000.00 / set -

$1500.00 / set

$1500.00 / set -

$5299.00 / set

$5299.00 / set -

$1499.00 / set

$1499.00 / set