High Quality 12m CNC Metal Sheet Double Tandem CNC Hydraulic Bending Machine Large Bending Machine

-

Supplier: Maanshan Gilde CNC Machine Tool Co., Ltd. -

Region: Anhui, China -

Contact: Mr ryan lee -

Price: $30000.00 /set -

Min. Order: 1 set

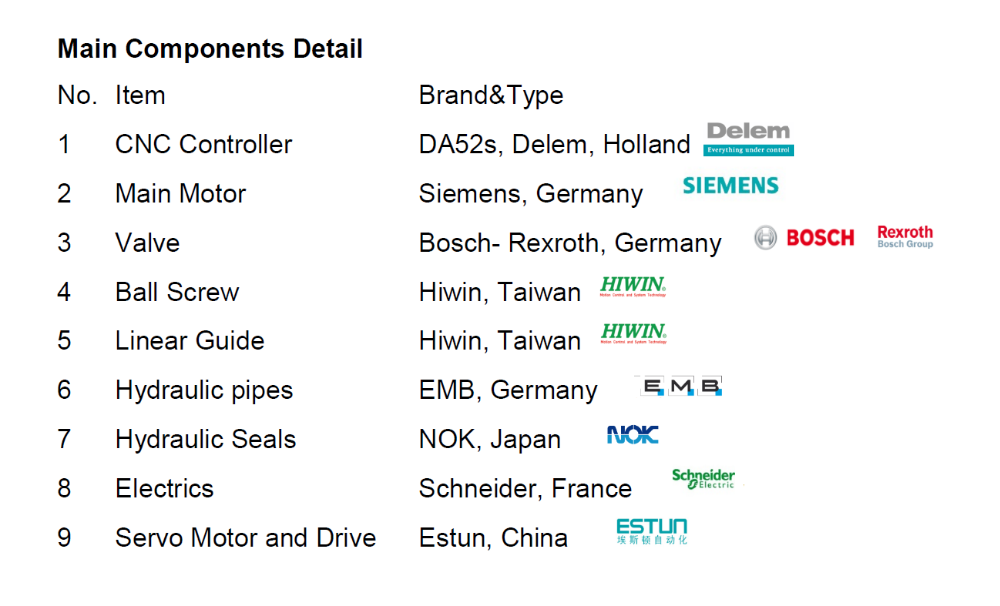

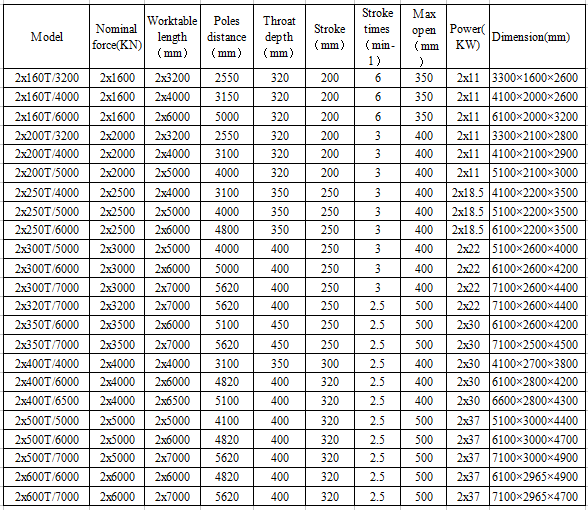

| Applicable industries: | Mechanical Repair Shops, Manufacturing Plants, Construction Engineering, Energy and Mining | Model: | 2-WC67K |

| Core Components Warranty: | 3 years | Table length (mm): | 3300 mm |

| thing: | CNC bending machine | Mechanical test report: | if |

| Showroom location: | not any | Electrical: | French Schneider |

| Table width (mm): | 2600 mm | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Pump: | Bosch, the first | Slider stroke (mm): | 2550 mm |

| Video external inspection: | if | color: | can be customized |

| Packaging Details: | Wooden packaging or adjustable to confirm its safety | automation: | automatic |

| Health status: | new | place of origin; place of origin: | Anhui, China |

| Extra Services: | end forming | brand: | GLDMA |

| Raw materials: | iron plate | Main selling point: | automatic |

| Motor power (kW): | 50kW | usage: | Bending Sheet Metal |

| Grating ruler: | HEIDENHAIN Germany | Main motor: | Siemens Germany |

| Warranty: | 3 years | Supply capacity: | Monthly output of 300 CNC bending machines 12m |

| HS code: | 8462219000 | Material/Metal Finishing: | Stainless steel, carbon steel, aluminum |

| Marketing Type: | normal product | Core components: | Motor, PLC, engine |

| port: | Shanghai | Auto level: | Fully automatic |

| Weight (kg): | 89000 | Type of machine: | Synchronous |

| Throat depth (mm): | 320 mm | year: | 2022 |

| aspect: | 7200*2900*4100 |

High Quality 12m CNC Metal Sheet Double Tandem Large CNC Hydraulic Bending Machine

Standard equipment:

scope:

1. Main features:

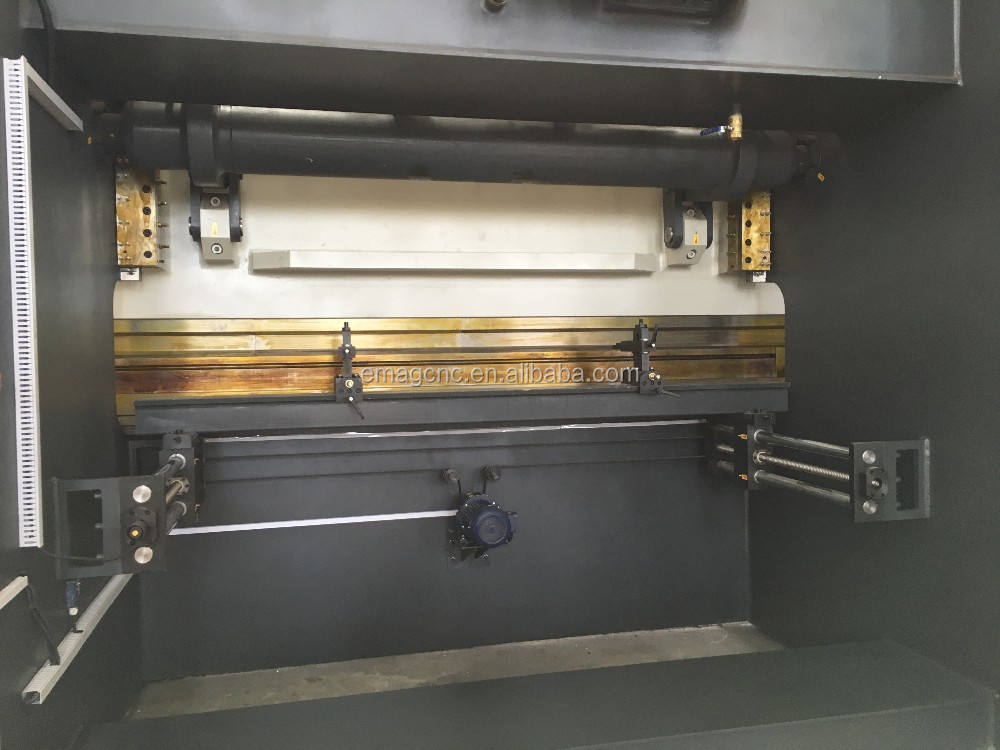

1) Fully EU streamlined design, stress relief process for welding robots and equipment as a whole and annealing treatment.

2) The WC67K series is one of the highest rated machines, its user friendly CNC controller and low cost hydraulic maintenance will help you increase productivity and keep costs to a minimum.

3) Automatic axis reference and calibration at power on.

4) Rigid upper beam runs on 8-point bearings with a bending accuracy of 0.01 mm.

5) Well-known top and bottom tool brands are durable and provide precise bends. Silent high pressure pump.

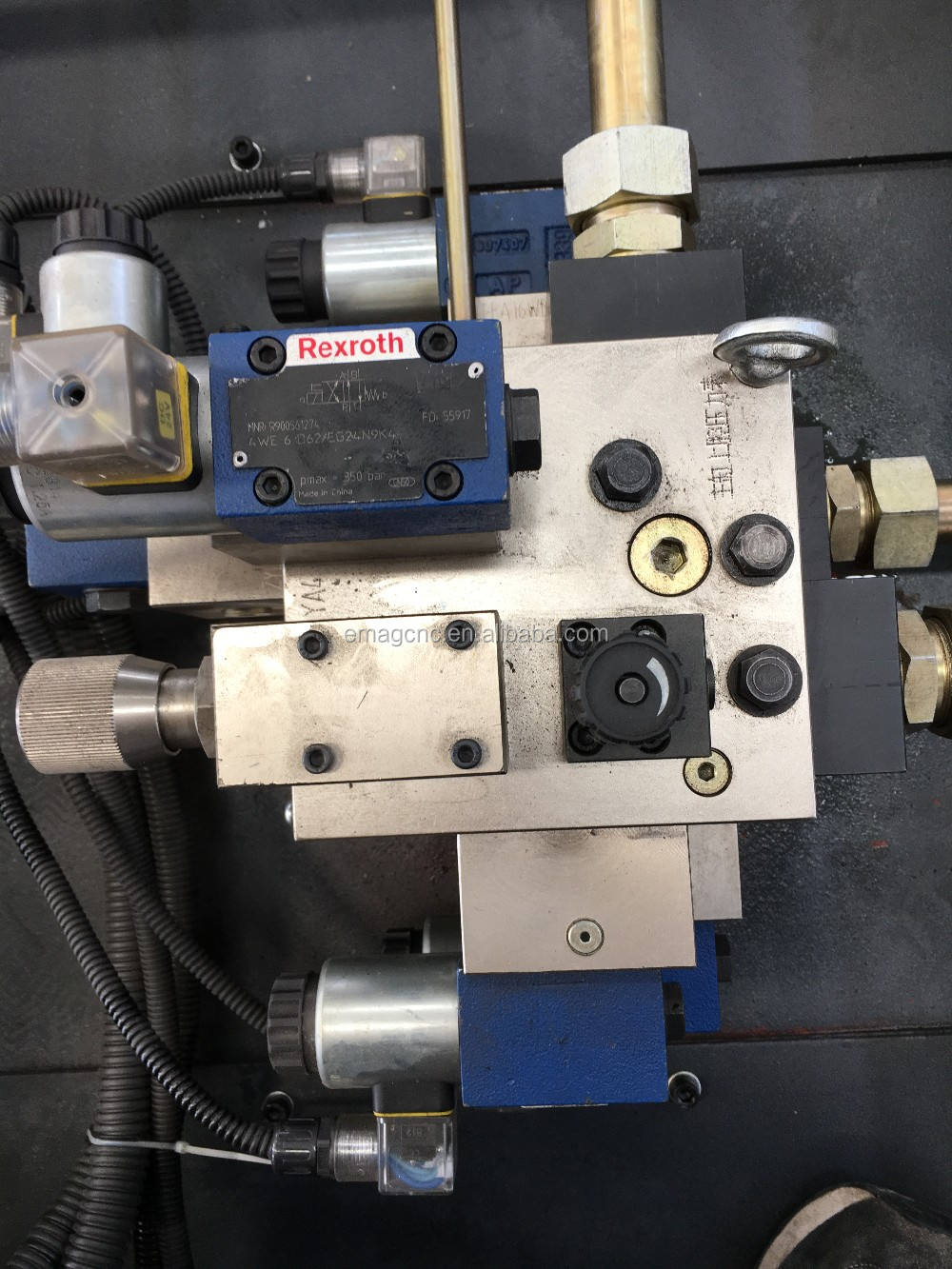

2. Hydraulic system:

1) The hydraulic control system consists ofBosch RexrothGermany orfirstU.S.

2) Japanese oil seal,NOK.

3) Overload and overflow protection to ensure no leakage, protect the hydraulic system,

And can directly read the oil level.

3.CNC back gauge:

1) CNC back gauge system, X axis is driven by AC servo motor, ball screw axis and linear

Bearings with an accuracy of 0.01mm.

2) The rear stopper adopts a tank type stopper structure with sufficient mechanical strength and rigidity.

3) High precision ball screw and linear guide. Special finger stop design,

Expand the back gauge range.

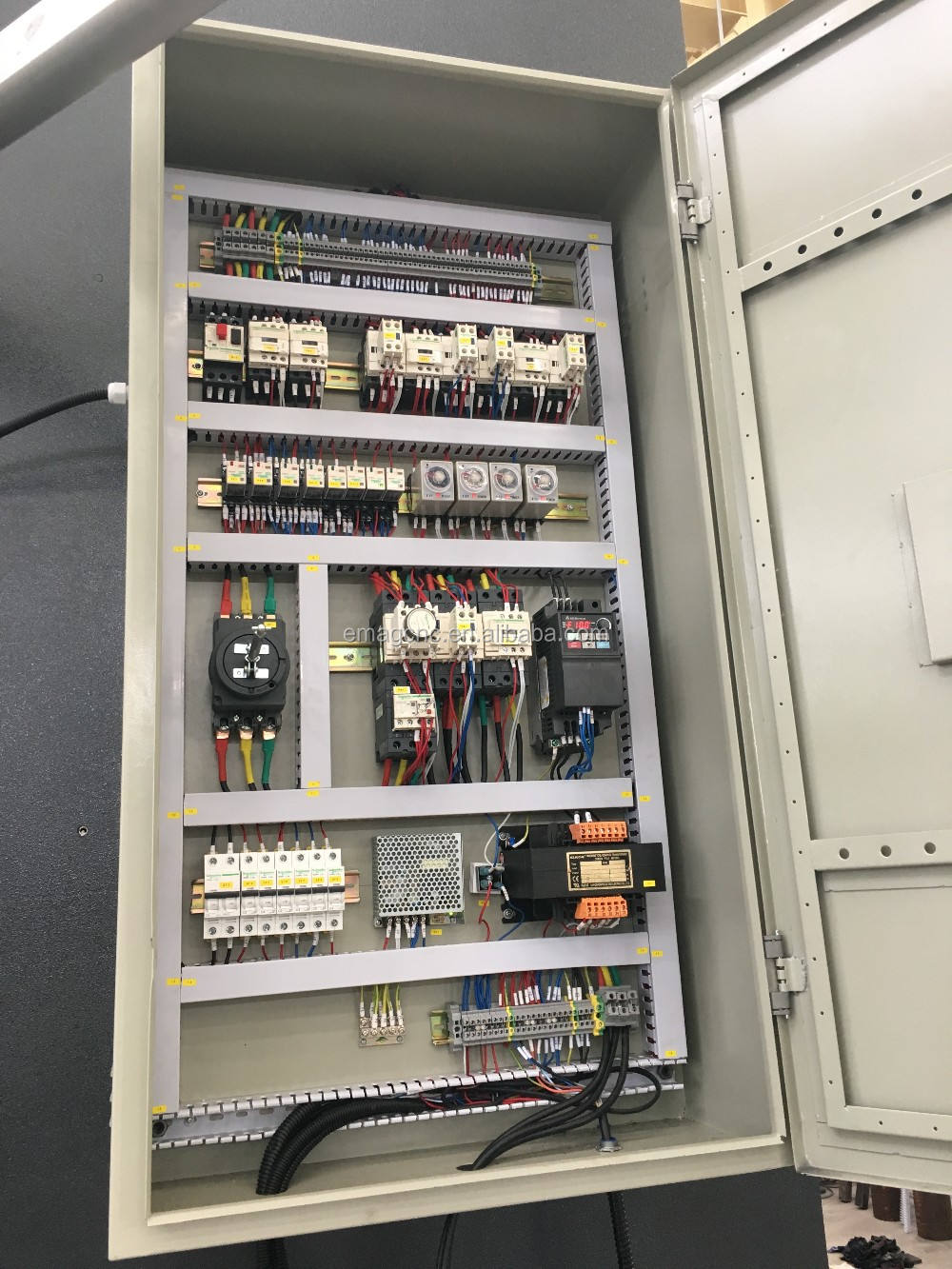

4. Electrical components and protection devices:

1) Schneider or Siemens low voltage equipment. According to international standards,

Safe and reliable, long life, strong anti-interference ability, the electrical cabinet is equipped with radiation unit.

2) Protective fences and safety interlocks ensure safe operation. With a removable one-hand foot switch, it is easy to operate.

3) Light screen protection.

5. Control system: optional: DA 52S, DA 56S, DA 58T, DA 66T, DA 69T, etc.

Rear view:

Mould:

CNC system from ELGO, Germany, or you can choose by yourself:

After regulations:

Germany Siemens motor:

Germany Bosch Rexroth valve:

French Schneider Electric:

Light curtain:

-

Manual or pneumatic table stainless steel sheet metal / sheet metal bending machine / plate bending machine

-

DAMA TP10 Hydraulic Press Brake Large Heavy Duty CNC Controller Hot Selling Press Brake

-

CAC-75W hydraulic angle steel bending machine

-

AH Press Brakes for (Manual, Hydraulic, NC Hydraulic, Manual Folding Machine, Power)

-

2022 European high standard low cost MB8 series 200Tons/3200 CNC bending machine for sale

-

3KW Plate Bending Machine Hydraulic Multifunctional Steel Plate Bending Machine

-

Manual Sheet Bending Machine Hydraulic Bending Machine Metal Bending Machine

-

(W1.0X610B, W1.0X915B, W1.5X1220Z ) small handbrake/disc & box brake with CE, best price

-

Tool molds on bending machines, press blades on bending machines

-

Hot selling hydraulic new bending machine sheet metal bending machine 80t 3000 4000 6000

Other Products

-

$800.00 / set

$800.00 / set -

$35000.00 / set

$35000.00 / set -

$3000.00 / set

$3000.00 / set -

$2500.00 / set

$2500.00 / set