Fully automatic small textile dyeing machine

-

Supplier: Wuxi Sunsky Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Barry Wang -

Price: $15000.00 /set -

Min. Order: 1 set

| Supply capacity: | 15 sets per month | strength: | 1200kgs/main pump 18.5KW |

| Certification: | ISO9001, CE | Warranty: | 1 year |

| After-sales service provided: | Engineers can service machinery overseas, on-site installation, commissioning and training | Inverter: | mitsubishi |

| payment terms: | letter of credit, wire transfer | programmable logic controller: | mitsubishi |

| Running speed: | 450 m/min | Controller: | EPC T15 or SETEX 777 +PLC |

| weight: | 1200 kg: 5 tons | Production capacity: | 300kg per tube |

| Maximum operating temperature: | 140'C | Packaging Preview: | |

| Mechanical test report: | if | Core Components Warranty: | 1 year |

| After Warranty Service: | Spare parts, on-site maintenance and repair services | Marketing Type: | Hot Products of 2019 |

| Dimensions (L*W*H): | 1200kgs:7100*5400*3400mm | Auto grade: | automatic |

| brand: | sunny | Weaving system: | XY |

| Stainless steel: | S31603(316L) | Applicable industries: | manufacturing plant, textile industry |

| Video external inspection: | if | Core components: | Pressure Vessels, Pumps |

| Voltage: | 380V/50Hz (optional) | Packaging Details: | Packed according to container export standard. |

| place of origin; place of origin: | Jiangsu, China | port: | Shanghai |

| Local service location: | Vietnam, Peru, Indonesia, Pakistan, India, Mexico, Sri Lanka, Bangladesh | Health status: | new |

| Maximum working pressure: | 0.36Mpa | Showroom location: | Vietnam, Peru, Indonesia, Pakistan, Sri Lanka, Bangladesh, Ukraine |

| Low alcohol ratio: | 1:3.5~4.5 |

OH seriesLow liquor ratio, low power consumption, low maintenance costHigh temperature and high pressure overflow O-type fabric dyeing machine is suitable for scouring/bleaching/dyeing/washing of all kinds of knitted and woven fabrics: cotton, modal, viscose, tencel, rayon, wool, acrylic, lyocell, nylon , polyester blends and lycra blends, etc.

The machine is designed and manufactured in accordance with the pressure vessel standard GB 150, with a maximum working temperature of 140 degrees and a maximum working pressure of 0.36Mpa. All parts in contact with dye liquor are made of corrosion-resistant stainless steel S31603 (316L) material. The specially designed nozzle structure makes the fabric in a loose and expanded state during the dyeing process. It has excellent performance in dyeing tight and heavy fabrics and can eliminate crease problems common with other dyeing machines. At the same time, the machine has two rope loading capacity.

- HT-HP dyeing machine, low liquid ratio; 1:3.5~4.5 (100% cotton max 1:4.5).

- Running speed: 450M/min

- Maximum operating temperature: 140'C

- Maximum working pressure: 0.36Mpa

- Heating rate: 25~100'C average 5'C per minute, 100~130'C average 2.5'C per minute (dry saturated steam pressure: 0.7Mpa)

- Cooling speed: 130~100'C average 3'C per minute, 100~85'C average 2'C per minute (cooling water pressure: 0.3Mpa, 25'C).

| Model | number of tubes | Load (KG) | Length(mm) | Width(mm) | Height(mm) | Main pump | Operating power (KW) |

| Power(KW) | |||||||

| OH-300-1 | 1 | 300 | 3500 | 5400 | 3400 | 5.5 | 13 |

| OH-300-2 | 2 | 600 | 4800 | 5400 | 3400 | 7.5 | 19 |

| OH-300-3 | 3 | 900 | 5900 | 5400 | 3400 | 15 | 26 |

| OH-300-4 | 4 | 1200 | 7100 | 5400 | 3400 | 18.5 | 34 |

| OH-300-6 | 6 | 1800 | 9500 | 5400 | 3400 | 37 | 54 |

| OH-300-8 | 8 | 2400 | 12500 | 5400 | 3400 | 45 | 58 |

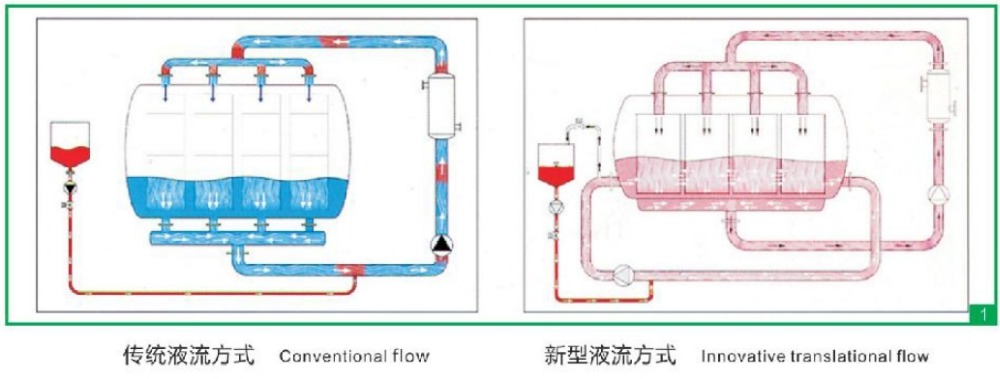

Superior performance using new technologies:

- The vertical heat exchanger of the low liquor ratio dyeing machine can discharge the condensed water instantly, reduce the switching time of hot and cold water, avoid the formation of scale, and prolong the service life of the heat exchanger.

- Optimize the water inlet pipe of the main pump, reduce the water inlet height, and significantly reduce the water consumption.

- The U-shaped groove and synchronous weaving system increase the load-carrying capacity by 20%, and the multi-directional weaving at the same time completely avoids the problem of entanglement.

- The leading dyeing control system, combined with double-balanced feeding system and constant pressure and stable flow, ensures uniform dyeing.

- The height of the machine and the operating platform is reduced, the size of the operating platform is reduced, and the operation is more convenient. The bottom of the dyeing tank is specially designed to effectively reduce the water storage and the bath ratio.

- The unique main vat circulation system controls the temperature difference between the top and bottom of the entire dye vat and the uniformity of feeding in the best state.

- The main tank is cleaned by rotary spray, and the entire tank is cleaned thoroughly within the cleaning range.

- The dye liquor runs vertically, the dye liquor runs vertically and the multi-directional suction system greatly reduces the liquor ratio and optimizes the dye liquor uniformity.

Environmental protection, energy saving and high efficiency:

- The low liquor ratio dyeing machine greatly reduces the water consumption.

- Compared with traditional dyeing machines, water, auxiliaries and steam consumption can be saved by 50%

- Lowest installed power and therefore lowest power consumption.

- Fast dye cycles for increased productivity.Larger capacity, 300 kg per tube.

- User-friendly operation and easy maintenance.

-

High temperature and high pressure medical material gauze bleaching machine

-

Tubular knitted fabric overfeed expander spreading machine

-

Polyester Dyeing Machine

-

DGNT Fine Fabric Dyeing Machine

-

Electric single-sided leather side dyeing machine semi-automatic belt side color painting box

-

High temperature sample staining machine (glycerol), laboratory staining machine

-

Normal temperature dyeing machine

-

High temperature and high pressure fiber dyeing machine

-

Steam-Heated Chain Ironing Machine

-

Best Quality Fabric Dyeing Machine / Industrial Washing Machine / Wool Washing Machine

Other Products

-

$30000.00 / set

$30000.00 / set -

$10000.00 / set

$10000.00 / set -

$15000.00 / set

$15000.00 / set