100% safe VOC waste gas treatment regenerative thermal oxidizer RTO

-

Supplier: Tianhua Institute Of Chemical Machinery And Automation Co., Ltd. -

Region: Gansu, China -

Contact: Ms Candy Liu -

Price: $250000.00 /set -

Min. Order: 1 set

Product details

| Video external inspection: | if | Application areas: | Coatings, Pharmaceuticals, Printing, Semiconductors, Petrochemicals |

| place of origin; place of origin: | Gansu, China | Core components: | engine, motor |

| Marketing Type: | normal product | brand: | Tianhua |

| Air volume: | 5000~100000Nm3/h | Focus: | 1000mg/Nm ~ 25%LEL |

| Purification efficiency: | 98% | Gas composition: | Complex (no recycling value, difficult to reuse) |

| Mechanical test report: | if | Health status: | new |

| Applicable industries: | Energy and Mining, Chemical | Weight (kg): | 400,000 kg |

| payment terms: | letter of credit, wire transfer | Packaging Preview: | |

| product name: | Regenerative thermal oxidizer | Thermal efficiency: | ≥95% |

| Showroom location: | not any | Supply capacity: | 100 sets per year |

| Warranty: | 3 years | port: | Shanghai, Guangzhou, Shenzhen, Xiamen |

| usage: | Exhaust gas treatment equipment | working principle: | Convert VOCs to CO2 and H2O |

| Core Components Warranty: | 3 years | Packaging Details: | wooden box |

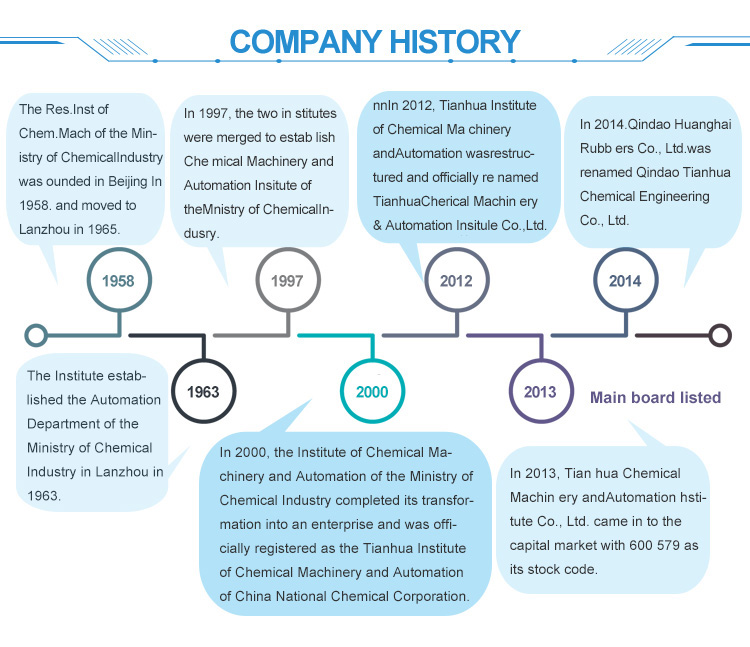

3D View Factory -64 years oldChemical industry experience

Virtual Reality

Virtual Reality

Product Description

Regenerative Thermal Oxidizer (RTO) is an efficient organic waste gas treatment equipment. The principle is to oxidize the organic compounds (VOCs) in the exhaust gas into carbon dioxide and water at high temperature, purify the exhaust gas and recover the waste heat released by decomposition,High thermal efficiency (95%), Low operating cost, handling large air volume and low concentration gas, etc. The main structure of RTO is composed of combustion chamber, regenerator and switching valve.

Advantage:

1.High thermal efficiency (above 95%) and significant energy saving effect. Under suitable exhaust gas concentration, self-heating operation can be achieved (eg 1.5g/Nm3 for toluene).

2. The purification rate is high, the purification rate of the two-bed RTO is over 98%, and the purification rate of the three-bed RTO is over 99%. Low operation and maintenance costs.

3. Fully automatic control, reliable operation and convenient operation.

4. Adopt multi-level security protection, safe equipment operation.

5. RCO (Regenerative Catalytic Oxidizer) can be performed using a catalyst.

Regenerative Thermal Oxidizer (RTO) is an energy-saving and environmentally friendly device for treating volatile organic waste gas. Its extremely high VOCs removal rate and thermal efficiency can not only make the final emission meet the national emission control requirements, but also greatly reduce the cost of waste gas treatment and production energy costs. Tianhuayuan Environmental Protection Institute isThe first RTO in China. The Regenerative Thermal Oxidizer (RTO) developed by it has obtained the national patent (ZL012088404). Torch projects and national key new products have independent intellectual property rights and have been awardedUsed in maleic anhydride, coatings, coatings, petrochemicals, electronics and other industries. Because of its reliable operation, simple operation, low operating cost, high purification rate and remarkable energy saving effect, etc.It is well received by people in the industry and has become the first choice for organic waste gas treatment in various industries..for many years,The domestic sales of similar products are the first, and a good brand has been established.

Advantage:

1.High thermal efficiency (above 95%) and significant energy saving effect. Under suitable exhaust gas concentration, self-heating operation can be achieved (eg 1.5g/Nm3 for toluene).

2. The purification rate is high, the purification rate of the two-bed RTO is over 98%, and the purification rate of the three-bed RTO is over 99%. Low operation and maintenance costs.

3. Fully automatic control, reliable operation and convenient operation.

4. Adopt multi-level security protection, safe equipment operation.

5. RCO (Regenerative Catalytic Oxidizer) can be performed using a catalyst.

6.No secondary pollution7. Long service life, low operating cost and simple maintenance

application:

1. Suitable for coating, coating, pharmaceutical, printing, semiconductor, petrochemical and other industries.

2. Quantity: 5000~100000 Nm3/h

3. Composition: complex, no recycling value, difficult to reuse

4. Concentration: 1000mg/Nm3

application:

1. Suitable for coating, coating, pharmaceutical, printing, semiconductor, petrochemical and other industries.

2. Quantity: 5000~100000 Nm3/h

3. Composition: complex, no recycling value, difficult to reuse

4. Concentration: 1000mg/Nm3

product name | Regenerative thermal oxidizer |

usage | Exhaust gas treatment equipment |

Air volume | 5000~100000Nm3/h |

Application field | Coatings, Pharmaceuticals, Printing, Semiconductors, Petrochemicals |

focus | 1000mg/Nm ~ 25%LEL |

gas composition | Complex (no recycling value, difficult to reuse) |

working principle | Convert VOCs to CO2 and H2O |

Thermal efficiency | ≥95% |

VIEW MORE

You may like

-

Biogas purification system Biogas purification system Biogas filter

-

Auto repair shop smoke arm/automobile exhaust extraction arm

-

Silicon Carbide DPF Diesel Particulate Filter Honeycomb Catalytic Converter DPF Catalyst Diesel Particulate Filter

-

Waste gas treatment equipment/organic waste gas treatment industrial catalytic combustion equipment

-

Ozone Destroyer Catalyst for Ozone Generators to Convert Ozone Gas Back to Oxygen

-

Industrial dust collector PPC type dust collector PPC96-4 bag filter dust collector is on sale

-

60M vehicle-mounted water mist cannon for agriculture and urban greening

-

Wuxi Xi Chuangjia Diesel Oxidation Catalyst (DOC) Honeycomb Ceramic Cordierite Carbon Removal Filter Catalyst Best Price

-

DR AIRE 98% smoke extraction rate 20% cost savings in kitchen eco-unit price

-

factory direct sale air purifier electrostatic precipitator esp for dop recycle