Tianjin EJON T13 3D Letter Sign Making Multi-channel Letter Bending Machine

-

Supplier: Tianjin Ejon Flying Science And Technology Co., Ltd. -

Region: Tianjin, China -

Contact: Mr Ejon Tianjin -

Price: $10000.00 / 1 - 4 sets

$9000.00 / >=5 sets -

Min. Order: 1 set

| Certification: | ce | Packaging Preview: | |

| automation: | automatic | Mechanical test report: | if |

| Material/Metal Finishing: | Aluminum alloy, aluminum, alloy, stainless steel, galvanized sheet | Core components: | Engine, motor, servo |

| Weight (kg): | 500 | Main selling point: | multifunctional |

| brand: | Ejon | Marketing Type: | New Products 2020 |

| Warranty: | 1 year | Showroom location: | Egypt, Canada, Turkey, Italy, Germany, Vietnam, Mexico, Russia, Morocco, South Korea |

| Applicable industries: | Printing shops, hotels, household goods, manufacturing plants, food stores, advertising agencies, restaurants, building materials stores | Core Components Warranty: | 1 year |

| After-sales service provided: | online, video support | payment terms: | letter of credit, wire transfer |

| Packaging Details: | The normal packing is wooden box (size: L*W*H). If exported to European countries, the wooden box will be fumigated. If the container is too tight, we will use pe film packaging or according to customer special requirements | place of origin; place of origin: | Tianjing, China |

| Supply capacity: | 8800 units per year | port: | Tianjin |

| Health status: | new | Video external inspection: | if |

| year: | 2022 |

Overview

detail

Place of Origin: Tianjin, China Brand Name: EJON

Condition: New Model Type: T13 Applicable Materials: Stainless Steel, Galvanized Sheet, Aluminum Sheet and Profile Automatic: Automatic

After-sales service: video/online support, engineer service force: CNC

Slotting method:Face and Wheel MillsGrooving stroke: 10-130mm

bending method:Dual Tool Alternate Bending System Core Warranty: 1 year

Material thickness: 0.4-1.2mm Minimum bending angle:R6

Certification:Chief ExecutiveMachine weight: 500kg

Supply capacity

Supply capacity: 8800 sets/year

Packaging and Shipping

phosphorusPackaging details: export fumigation-free wooden box

Port: Tianjin Port or other Chinese ports

Delivery time: 10-20 working days

Product Description

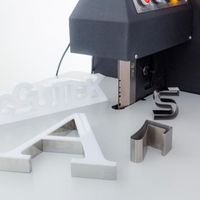

EJ0N S13 machine hasMultifunction Automatic bending machine, widely used in Seiko characters, resin characters, borderless characters, aluminum edge characters and other characters. Applicable materials are stainless steel, galvanized sheet, aluminum sheet, and aluminum profile.

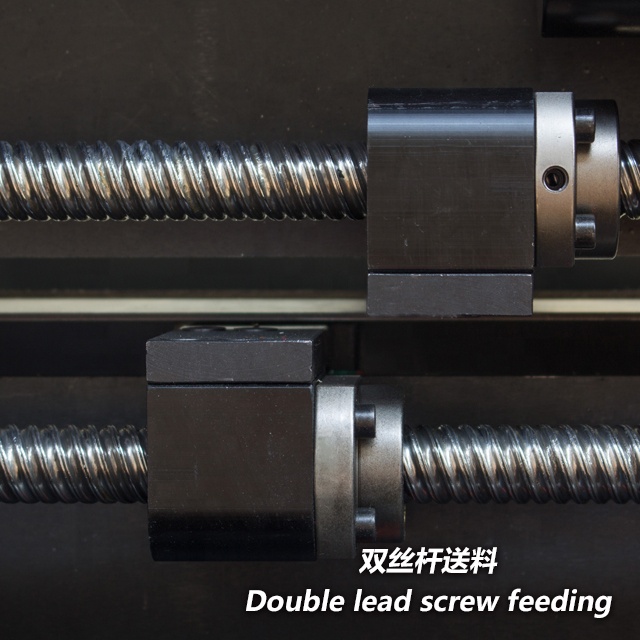

Alternate feeding structure of manipulator, tHis material clips are castIt can avoid scratching the material while improving the feed retention. The air pressure is used to press the material to avoid uneven material and ensure smooth feeding. Double ball screw with nylon gear drive, accurate positioning, greatly improve the feeding speed and the stability of the machine. specially designedThe super-long alternate feeding mechanism adopts

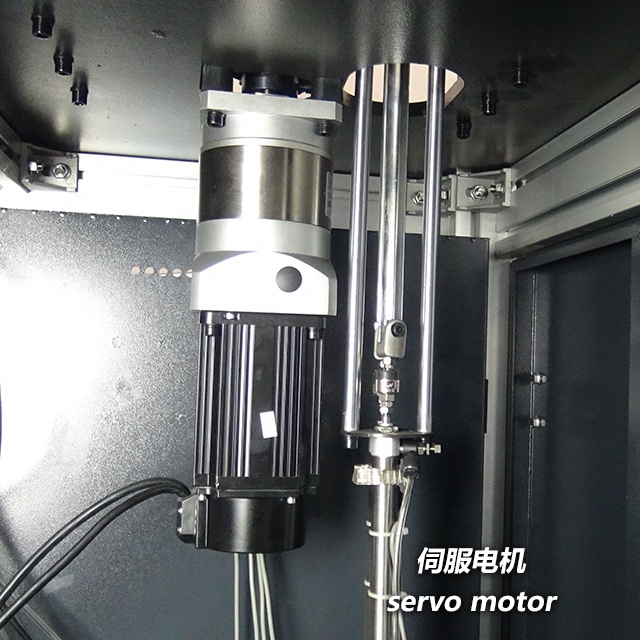

Servo control control systemAdopt high-quality twin-screw drive, with the following advantages

Large torque, high precision and fast speed ensure smooth feeding process and avoid

Material deformation.

Face milling cutters can groove a variety of materials. Linear guides are matched to ball screws and have750W high power servoThe motor greatly improves the feed speed and stability.

Slotting knives use high-strength alloy knives, each knife has 8 angles, no need to sharpen knives, and greatly improve the service life.

Double-blade alternating bending structure, machete structureDuctile Iron, good shock absorption, high structural strength, reduce the number of parts splicing,High power servo motor, High-speed bending is performed under the bending mechanism, and the bending mechanism is permanently deformed, which effectively improves the positioning accuracy and stability of high-speed bending.

| Specification | |

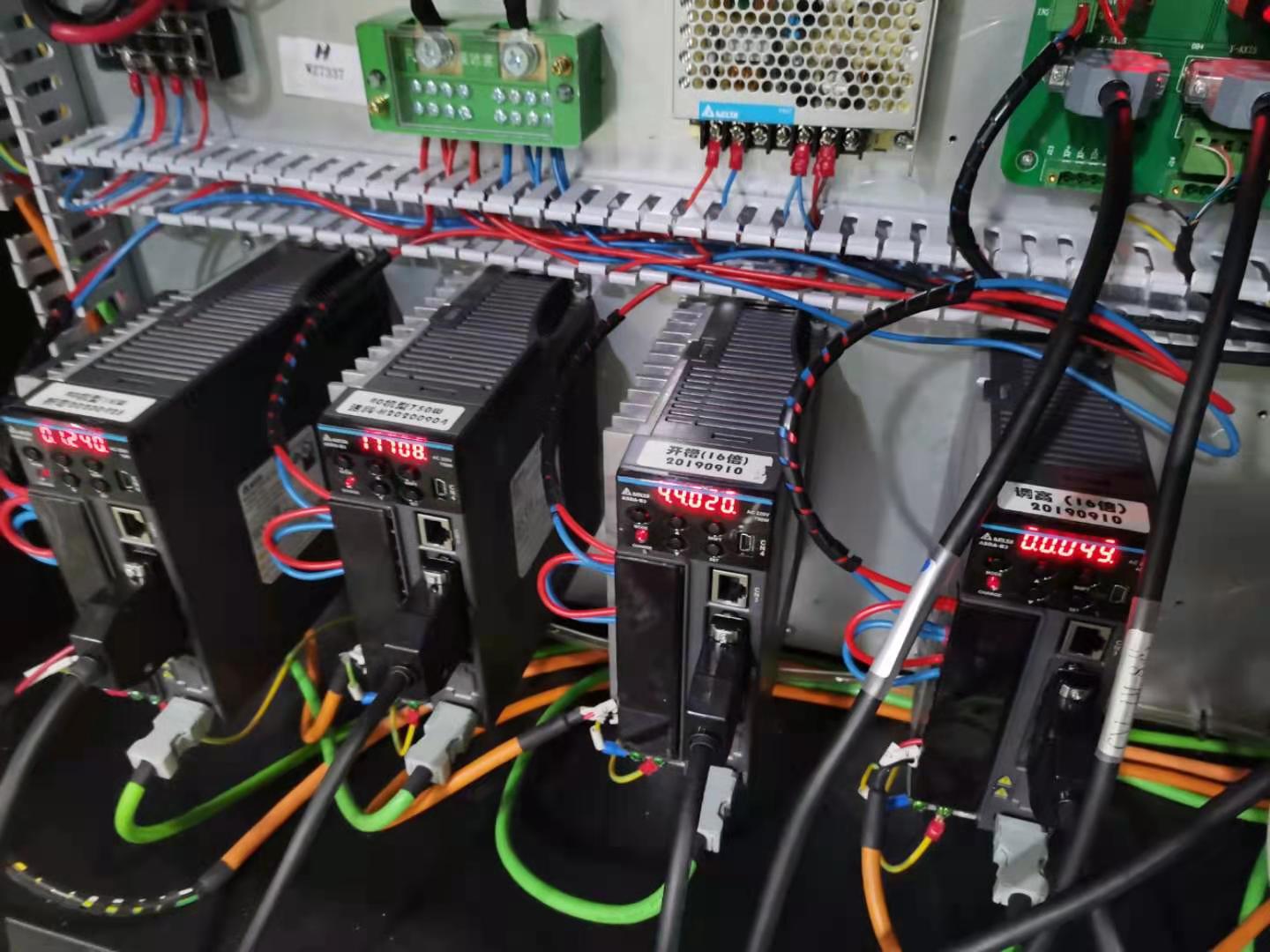

| system | 4 Full Delta servo axis control |

| feeding system | Circular Clamp Feeding System |

| Grooving system | Flat Knife Slotting & Milling Wheel Slotting System |

| Bending system | Dual Blade Alternate Bending System |

| Applicable materials | Stainless steel, galvanized sheet, aluminum sheet, aluminum profile |

| Slotting height |

Planer: 10-130mm Milling wheel cutter: 20-100mm |

| Material thickness | 0.4-1.2mm |

| Control System | 4 Full Delta servo axis control |

| Minimum bending angle | R6 |

| file format | Dxf.Plt.Ai |

| strength | AC220V, 50HZ, 3.0KW |

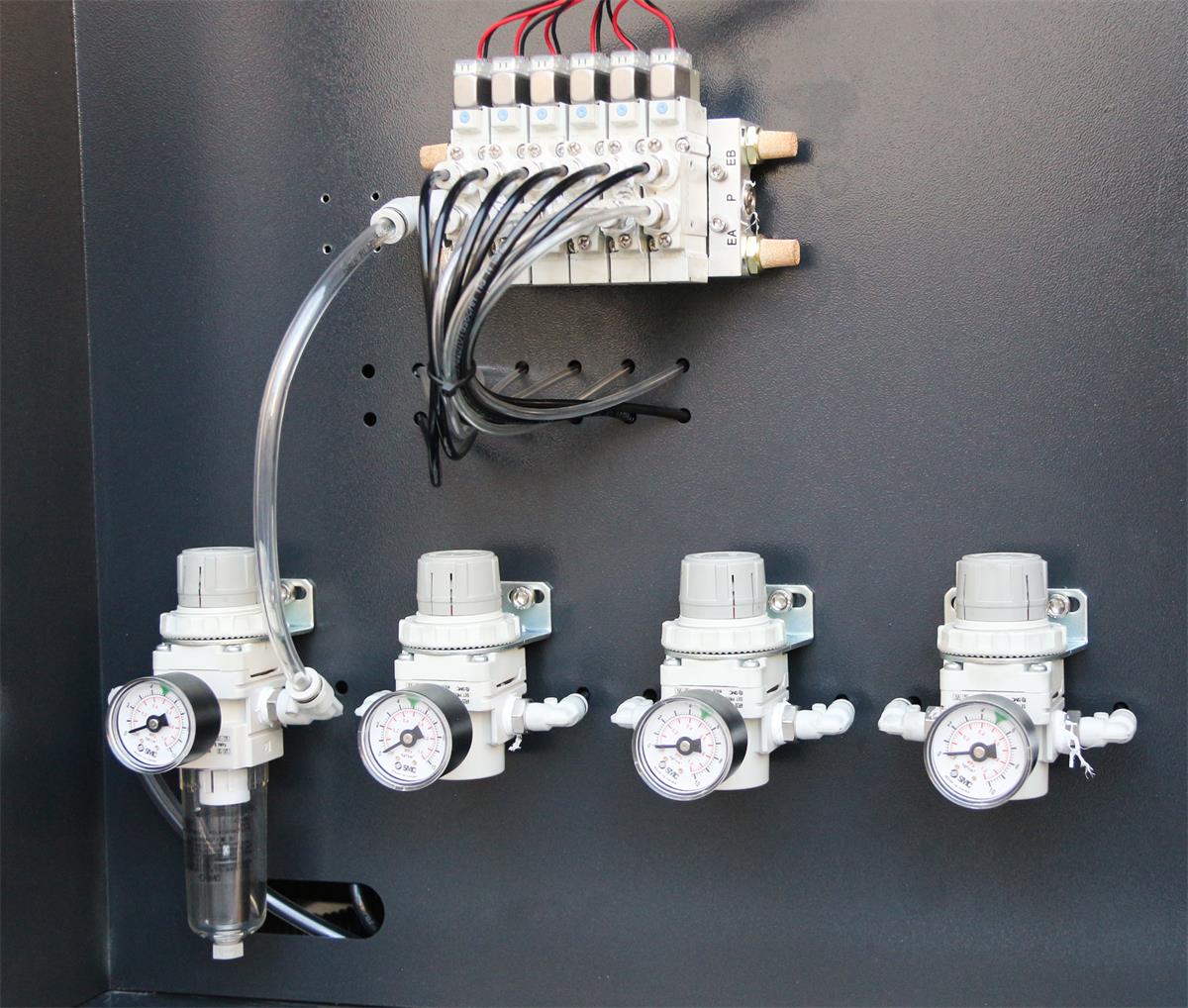

| Gas source | 0.6 m3/min |

| Package dimensions | 1410*750*1560mm 660*660*1110mm |

| Workspace | 2500*1100*1560mm |

| machine weight | 500kg |

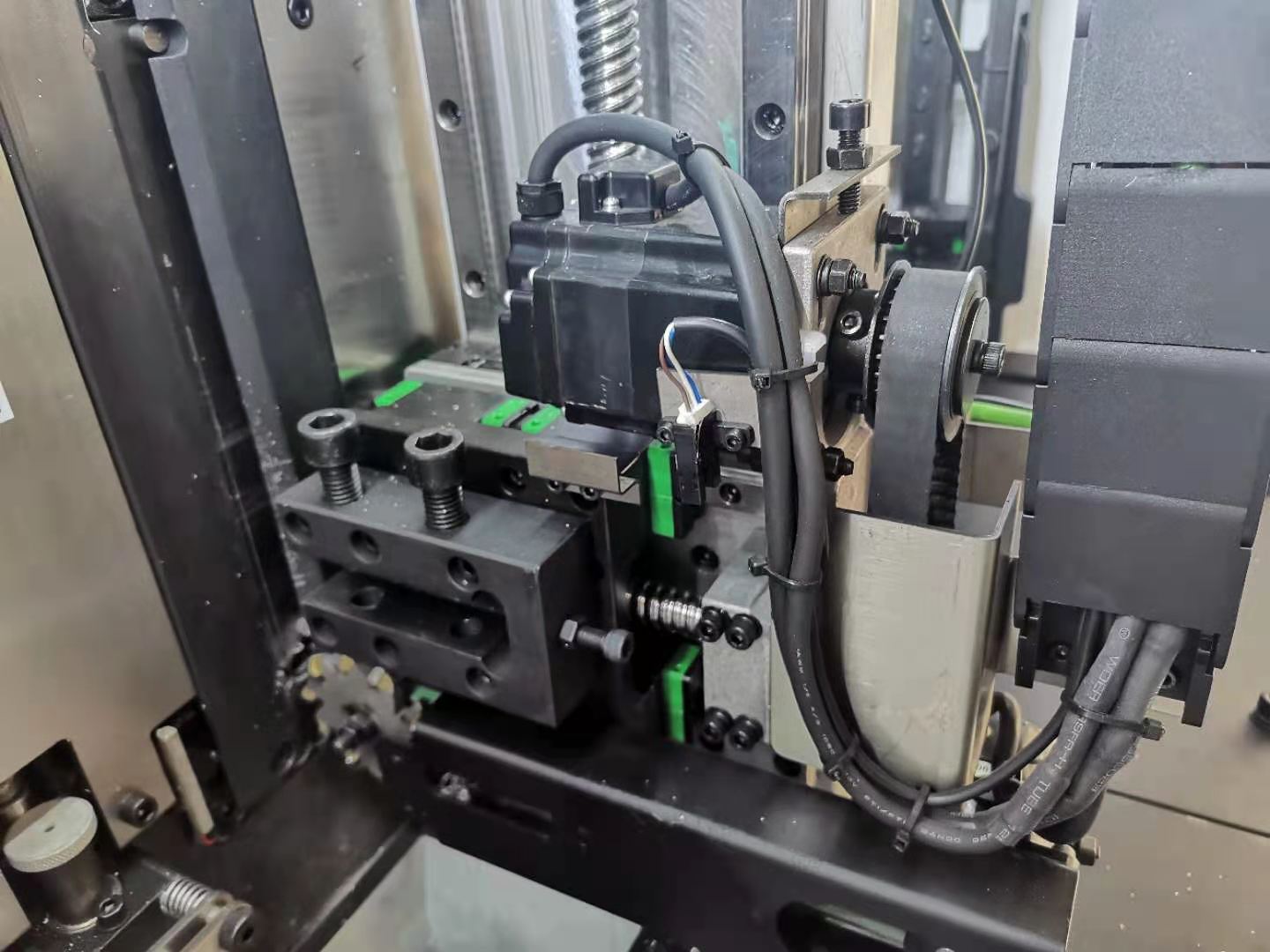

T13 Machine Part Details

Equipped with 4-axis high-power 750W full Delta servo control systemTono Ensure the accuracy and stability of feeding, grooving, heightening and bending.

Imported SMC electrical components, high stability

Durability.

Extra long bending span, lengthened by 20cm, effectively avoid

Affects the forming angle during processing.

Punch function for your choice.

Feeding parts :TThe feeding structure adopts double balls

The screw is matched with nylon gear drive to ensure

Precise positioning, smooth feeding, greatly improved

Feed speed and stability.

Grooving parts: double blade alternately grooving,were able

Production of stainless steel, galvanized sheet, aluminum sheet

Bending parts: Double-blade alternating bending system, using servo motor for bending, high torque, high forming

degree.

Sample display

How to learn machine operations

1. Operation manual U disk

Provide machine U disk, with detailed and specific English operation manual and video.

2. Network Services

Provide online services through WeChat, Whatsapp, Skype, E-mail, Team viewer.

3. Factory tour

Welcome customers to visit our factory to learn how to operate the machine.

Supporting facilities

Computer Pump File Format

To use the device you need to use the device should bend the software

Install the control card in your device The machine is self-developed. computer, then connect toAir compressor,We recommend importing supported formats

More options for press brakes and installationsDxf.Plt.Ai. we recommend

software computer. Compare4kW, the airflow uses Coredraw or adobe

Configuration:XP system or 0.6m3/Min illustrationto finish

window7 32-bit system, andfile after export

needa pcl card slotConvert to Dxf.Plt.Ai format. Then

Install controlscard.Open the operating software,

select document

exhibition

our company

Certification

Packaging and Shipping

our service

1. The whole machine is guaranteed for one year.

2. Free training courses in our factory or online.

3. After the warranty period, we will provide wearing parts

Purchase at agency price when replacement is required.

4. Before the machine is shipped, we will install all the parts and test machine for you. We will take the working video of the machine and the machine phone for you to check, if it is confirmed that there is no problem, we will ship it.

5. After the machine arrives, just connect the power supply, software, etc., it is easier for you. If you're concerned, we can shoot instructional videos for you. By the way, during the production of the machine, we can also share the process with you.

6. In terms of training, firstly we will shoot more teaching videos for you, we can also control remotely, and most importantly, if you need, we can provide our technicians for on-site training and on-site teaching. If you have time, welcome to visit our company, you can operate and learn the machine by yourself.

7. After the machine is shipped, I will prepare some documents, such as bill of lading, packing list, commercial invoice, sales contract, CE certification, to help you pick up the machine.

contact details

-

YIKE hot-selling LED advertising aluminum character bending machine, logo groove character making machine

-

27'' 700mm acrylic manual bending machine acrylic channel letter hot bending tool hot bending plastic hot bender heater

-

CNC automatic 3D advertising word bending machine / acrylic LED sign aluminum strip bending machine

-

220V 1000W 24" 600mm Acrylic Plastic PVC Bending Machine Heater Bending Machine

-

Automated cnc logo bending machine letter making channel letter bending machine

-

Manual Groove Bending Tool

-

Round ellipse rectangle automatic PLC control custom arc aluminum profile bending machine aluminum mirror frame bending machine

-

Metal slot word punching pliers stainless steel slot word advertising production puncher tool

-

TOP Accutek Hot Sale Automatic CNC Metal Channel Letter Bending Machine All in One Indoor and Outdoor Door Plate Bending Machine Special Sale

-

Automatic CNC Metal Channel Letter Bending Machine for 3d Aluminum Profile Paper