Six-color six-color flexo printing machine

-

Supplier: Ruian Songsheng Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Eileen Zhou -

Price: $10000.00 /set -

Min. Order: 1 set

| printing material: | Movie | Health status: | new |

| Warranty: | 1 year | Material: | iron |

| Colors and Pages: | Polychromatic | After-sales service provided: | Engineers can repair machinery overseas |

| type: | flexo printing press | Auto grade: | automatic |

| application: | available | Main selling point: | Polychromatic |

| Plate type: | flexo plate | usage: | Paper printer, roll film printing/non-woven roll printing/paper roll printing |

| Core components: | Pump, PLC | Video external inspection: | if |

| Dimensions (L*W*H): | 4500 X 2200 X 2450mm | Core Components Warranty: | 1 year |

| Applicable industries: | printing shop, advertising agency | payment terms: | L/C, Western Union, T/T, Cash |

| Supply capacity: | 10 sets per month | Name: | flexo printing press |

| Packaging Details: | Wrap in film and place in a suitable container | brand: | Matsumori |

| Voltage: | 380V | port: | Ningbo Port |

| place of origin; place of origin: | Zhejiang, China | printing speed: | 60m/min |

| Mechanical test report: | if | Certification: | CE ISO9001 |

| weight: | 3700kg | structure: | queue |

Applications

This machine is suitable for the printing of polyethylene, polyethylene plastic bags, cellophane, non-woven fabrics, roll paper and other packaging materials. It is an ideal printing equipment for the production of food paper packaging bags, supermarket handbags, vest bags and other packaging materials. clothes bag etc.

feature:

1. Easy to operate, flexible to start, accurate color registration.

2. The meter counter can set the number of prints as needed. Automatically stop when the quantity is reached or the material is cut off.

3. The pneumatic printing drum is lifted and lowered, and the ink is automatically stirred after lifting.

4. The anilox roller transmits the ink, and the ink color is uniform.

5. The reliable drying system cooperates with high-speed rotation, and the circuit is automatically cut off when it stops.

6.360° continuously adjustable longitudinal register device.

7. Frequency conversion speed regulation, adapt to different printing speeds.

8. There are jog/stop buttons on the plate roller seat and the reel stand, which are convenient to operate the machine when loading plates.

9. The unwinding tension control adopts magnetic powder brake. Magnetic powder clutch for winding tension control.

Host image:

company information:

Ruian Songsheng Machinery Co., Ltd.Located in China's plastic machinery production base - Ruian City. The company specializes in the production of film blowing machines, plastic bag machines and other supporting equipment for more than ten years. We pursue machine quality and innovation. We export our machines to Southeast Asia, Middle East, South Asia, Russia, North Asia, North America, Eastern Europe, Africa and other parts of the world. Welcome all countries to visit our company.

Pre-sale service: after-sale service

* Inquiry and consultation support. *Training how to install the machine, training how to use

* Sample testing support. machine.

* View our factory. * Engineers can repair machinery overseas.

* Pick-up from airports and stations.

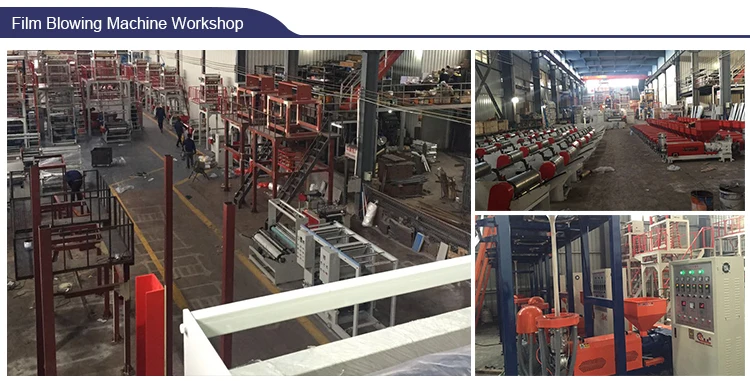

Film Blowing Machine Workshop & Printing Machine Workshop

Bag making machinery workshop

Picture 1

One. first film packaging

b. Moving the machine with a forklift

Put them one by one into the container.

Figure II

Tie the machine with iron wire

with container

Figures 3 & 4

One. close the container

b. On the way to the port of destination.

SS-FM series LDPE/HDPE plastic film blowing machine

99%reaction speed

SS-ABA series three-layer film co-extrusion machine

99%reaction speed

SS-GS Automatic High Speed Plastic Bag Making Machine

99% reaction speed

-

Flexographic Printing Machine Corrugated New High Speed Ci Woven Shopping Bag Flexographic Printing Machine

-

YT-4600 flexographic printing machine flexographic printing machine 6 colors

-

Flexo Label Printing Machine, High Quality Flexo Printing Machine, 8 Color Flexo Printing Machine

-

Online Monochrome Logo Flexo Printing Machine

-

2 Colors Non Woven Film Bag Flexo Printing Machine Plastic Paper Flexo Sachet Printing Machine Machinery

-

Fully automatic flexo printing machine printing machine

-

2 3 4 5 6-color paper cup blank fan-shaped printing punching machine

-

Digital label printing machine ZBRY-480

-

With Dryer Logo Flexographic Printing Machine Automatic Paper Bag Printer 1-5 Colors Non Woven Plastic Bag Printing Machine Printing Machine

-

Single color mini flexo printing machine

Other Products

-

$22000.00 / set

$22000.00 / set