Oilfield Drilling Rig Parts Shale Shaker, Drilling Mud Shale Shaker KyrgyzstanUzbekistanPhilippinesMalaysiaPakistanSouth Africa

-

Supplier: Dongying Qixiang Import & Export Co., Ltd. -

Region: Shandong, China -

Contact: Ms Eve Liu -

Price: $7500.00 /set -

Min. Order: 1 set

| weight: | 1650-2120 | Health status: | new |

| Applicable industries: | Mechanical Repair Shop Energy & Mining | Supply capacity: | 1000 sets per month |

| place of origin; place of origin: | Shandong China | payment terms: | L/C,T/T,Western Union |

| Packaging Preview: | Local service location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya , Argentina, South Korea, Chile, United Arab Emirates, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Tajikistan | |

| port: | Chinese port | feature: | low cost |

| Production capacity: | 80V/50HZ, 460V/60HZ | Dimensions (L*W*H): | 2400X1640X1450mm |

| Packaging Details: | export package | Warranty: | 18 months |

| Voltage: | 380V | Showroom location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile , UAE, Colombia, Algeria, Romania, South Africa, Kazakhstan, Ukraine, Uzbekistan, Japan, Malaysia |

| brand: | DYQX | Certification: | API |

| After-sales service provided: | Engineers can repair machinery overseas | model: | DYQX |

| application: | Solid control |

Oilfield drilling rig accessories vibrating screen, drilling mud vibrating screen

Brief introduction of vibrating screen

The vibrating screen is exclusively designed and manufactured by our company. It has the advantages of international similar products and has a number of patents.

The vibrating screen with high vibration intensity, adjustable pitch, compact structure, reliable performance and high cost performance is known as a competitive product in the international market.

1. Use and applicability

The drilling fluid vibrating screen is the main solids control equipment in the drilling fluid solids control system.

The vibrating screen screens the drilling fluid containing a large amount of cuttings, separates the large-sized solid particles, and transports the drilling fluid to the next separation equipment.

The vibrating screen has the advantages of simple structure, reliable performance, large processing capacity, long service life and simple maintenance.

2. Structure and working principle

The vibrating screen is composed of feeding tank, base, screen box, vibration motor, etc. Six isolation springs support the screen box on the base, and three identical or different screens are installed on the working surface of the screen box.

The vibrating screen absorbs the latest achievements of screening machines at home and abroad, combines the advantages of circular vibration and linear vibration, greatly improves the carrying speed of drill cuttings, and improves the screening amount of drilling fluid, thereby avoiding gelatinization on the screen. . . The vibrating screen uses double explosion-proof vibration motors as the vibration source, and forms linear motion under the action of the reverse vibration motor. It is especially suitable for working conditions with large formation fluctuations. The advantage is even more pronounced due to the higher viscosity of the drilling fluid.

3. Main technical parameters

Model | ZS280-3P | ZS240-3P | ZS220-3P | ZS180-2P |

Motor power, kW | 2×2.2 | 2×2.2 | 2×2.2 | 2×1.3 |

pre-degree | dⅡBT4 | dⅡBT4 | dⅡBT4 | dⅡBT4 |

Protection class | IP66 | IP66 | IP66 | IP66 |

Screen area, m2 | 3×0.833×1.15 | 3×0.7×1.15 | 3×0.7×1.05 | 2×0.833×1.15 |

Bilateral amplitude, mm | 6 | 6 | 6 | 6 |

Vibration frequency, Hz | 24.3 | 24.3 | 24.3 | 24.3 |

Vibration intensity | 7.2 g | 7.2 g | 7.2 g | 7.2 g |

capacity | 42 L/sec | 35 l/s | 30 l/s | 26 l/s |

Angle adjustment range | -2°~+6° | -2°~+6° | -2°~+6° | -2°~+6° |

Dimensions, mm | 3140×1980×1540 | 2710×1980×1540 | 2710×1870×1535 | 2300×1980×1285 |

weight, kg | 2120 | 2080 | 1950 | 1650 |

4. Working principle diagram:

-

API vibrating screen high-quality solids control equipment for oilfield trailer-mounted drilling rigs

-

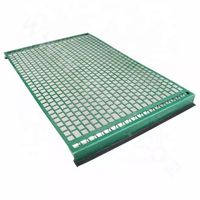

Vibrating screen mesh for oilfield solids control equipment

-

API 304/306 stainless steel frame shale shaker for mud filtration

-

Mud vibrating screen solids control system vibrating screen

-

JZCQ -240 series oilfield control system vacuum degasser

-

API Standard Oil Well Drilling Fluid Solid Control Vacuum Degasser

-

oilfield drilling nov brandt vsm 300 vibrating screen factory price

-

Manufacturer of high quality decanter centrifuges

-

API Standards Rigid Control System Twin Impeller Mud Agitator Professional Mixer

-

Shaker

Other Products

-

$200.00 / piece

$200.00 / piece -

$2000.00 / set

$2000.00 / set -

$20000.00 / set

$20000.00 / set -

$34000.00 / set

$34000.00 / set -

$1500.00 / set

$1500.00 / set -

$14000.00 / set

$14000.00 / set -

$1000.00 / set

$1000.00 / set -

$150.00 / set

$150.00 / set -

$14000.00 / set

$14000.00 / set -

$10.00 / piece

$10.00 / piece