Mobile Electric Glass Cart Glass Loading Robot

-

Supplier: Jinan Plk Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms Sarah Tian -

Price: $4500.00 /set -

Min. Order: 1 set

| Showroom location: | Egypt, Turkey, United Kingdom, Italy, France, Germany, Vietnam, Philippines, Brazil, Saudi Arabia, India, Russia, Spain, Morocco, Argentina, Chile, United Arab Emirates, Colombia, Nigeria, Japan, Malaysia, Australia | Marketing Type: | New Products 2020 |

| R: | see table below | Video external inspection: | if |

| Core components: | PLC, motor, pressure vessel, pump | Warranty: | 1 year |

| Health status: | new | Core Components Warranty: | 1 year |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,Paypal | brand: | PLK elevator |

| Packaging Preview: | Dimensions (L*W*H): | See below | |

| usage: | Transporting glass, marble or other flat objects | Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Mechanical Repair Stores, Manufacturing Plants, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Works, Energy and Mining, Food and Beverage Stores, Advertising Agencies |

| net weight: | see table below | After Warranty Service: | spare parts |

| Lifting height: | see table below | port: | Qingdao, Shanghai, Ningbo, Shenzhen or designated |

| feature: | Dual Independent Pneumatic Channels Smart Handle Durable Battery | Mechanical test report: | if |

| Weight (kg): | 1600 kg | application: | Building Decoration Factory Glass Company |

| Supply capacity: | 218 sets per year | place of origin; place of origin: | Shandong China |

| Packaging Details: | wooden box | color: | Blue Green Red or as your request |

| Packing Size/Material: | 3150mm*1100mm*1860mm wooden box | Optional control system: | remote control |

GL-LD series truck glass vacuum lifting equipment

GL-LD series truck glass vacuum lifting equipment

introduce

a) Electric drive, the trolley can drive effortlessly under high loads.

b) Durable battery guarantees longer working cycle.

c) High-quality hydraulic cylinders ensure zero risk of lifting and lowering of the telescopic boom.

d) All products are CE marked.

application:

It is widely used in the hoisting and handling of flat objects such as glass plates, metal blocks, marble blocks, and sandwich panels.

Sponge-type suction cups are specially manufactured to allow deformed objects to be pressed against irregularly shaped objects.

feature:

1. Double pneumatic channels to ensure safety. It maintains pressure even if one channel is cut off.

2.Versatile and flexible. The suction cup frame can move freely 180° horizontally and vertically, with optional remote control.

3. Telescopic design, reach farther and lift higher.

4. High-quality hydraulic cylinder to ensure good operation.

5. Durable battery and smart charger for extended duty cycle.

6. One YearFree replacement partsA policy against any mechanical and structural failure of non-human causes.

Click hereGet the latest offer...

Best Rated Trolley Vacuum Lifter: LD-600

|

Model type |

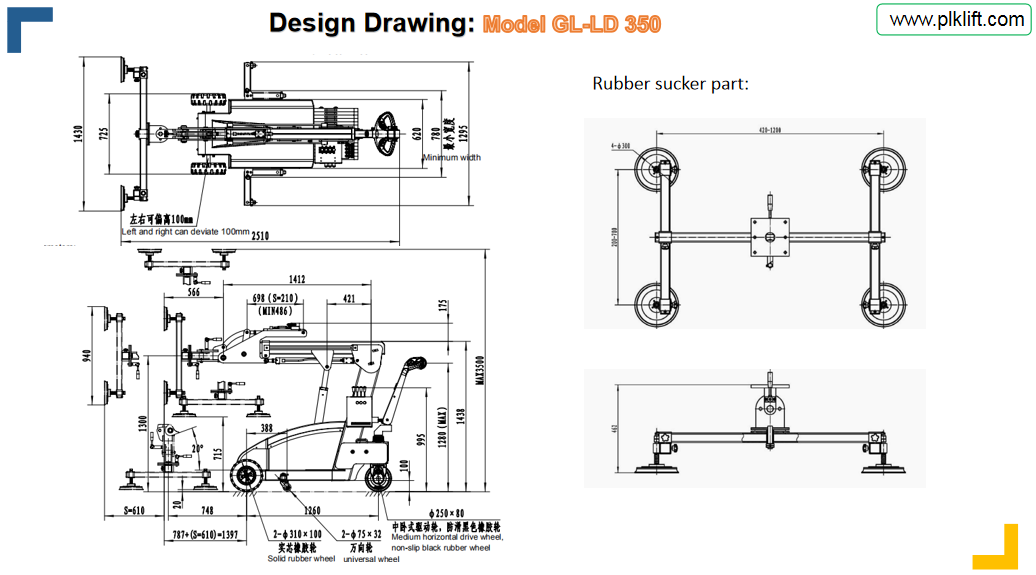

GL-LD-350 |

GL-LD-400 |

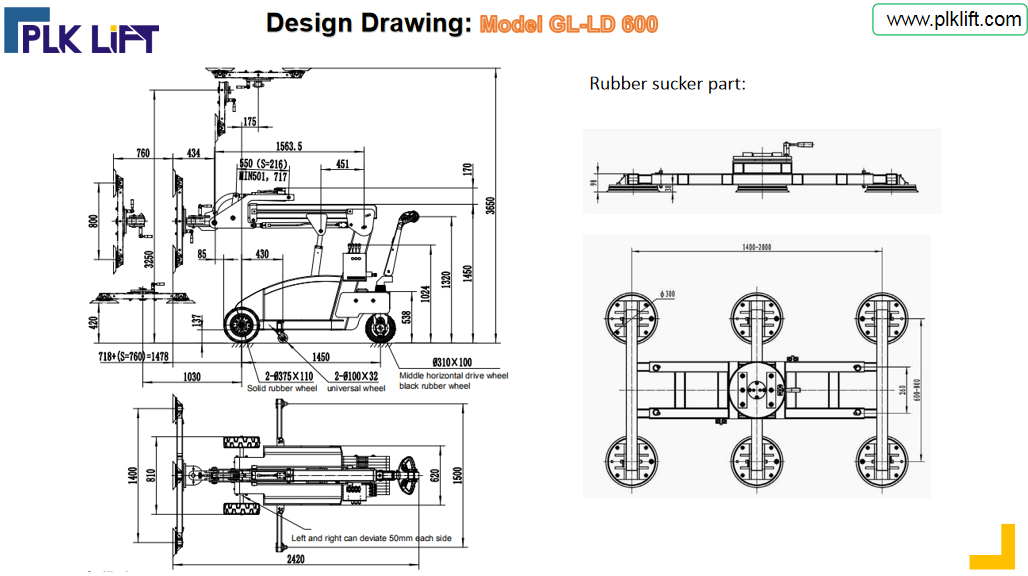

GL-LD-600 |

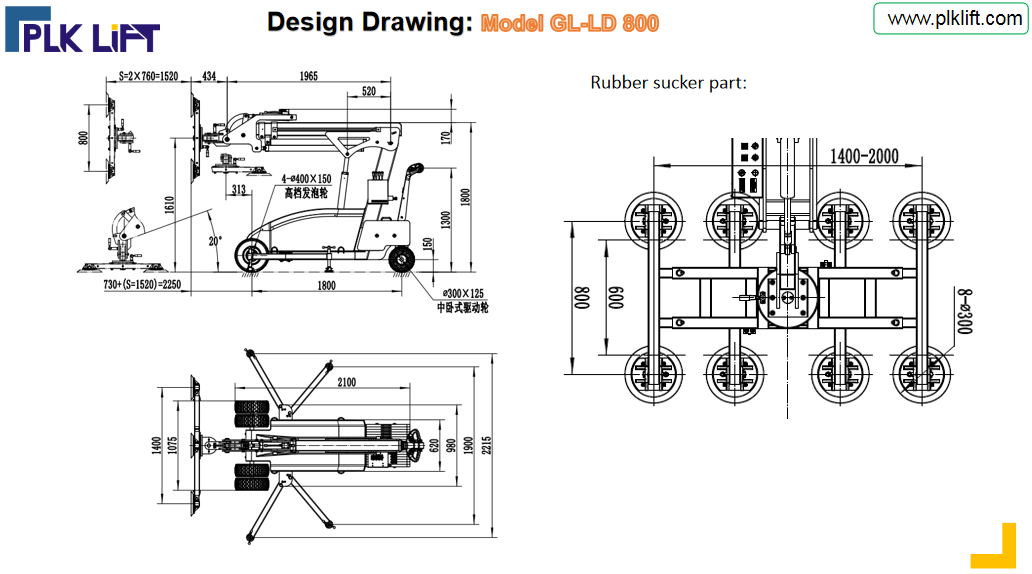

GL-LD-800 |

|

|

R |

350kg (arm retracted) |

400 kg (retracted) |

600 kg (retracted) |

800kg (retracted) |

|

|

175kg (extended) |

200 kg (extended) |

300 kg (extended) |

400 kg (extended) |

||

|

Lifting height |

3500mm |

3500mm |

3650mm |

5000mm |

|

|

Number of suction caps |

4 |

6 |

6 |

8 |

|

|

Rubber suction cover |

Ø300mm |

Ø300mm |

Ø300mm |

Ø300mm |

|

|

Maintenance free battery |

2x12V/100AH |

2x12V/100AH |

2x12V/120AH |

2x12V/120AH |

|

|

charger |

smart charger |

smart charger |

smart charger |

smart charger |

|

|

motor |

24V/600W |

24V/600W |

24V/900W |

24V/1200W |

|

|

Lifting motor |

24V/2000W/5L |

24V/2000W/5L |

24V/2000W/5L |

24V/2000W/12L |

|

|

front wheel |

Ø310x100mm |

Ø310x100mm |

Ø375x110mm |

Ø400x150mm |

|

|

drive wheel |

Ø250x80mm |

Ø250x80mm |

Ø310x100mm |

Ø300x125mm |

|

|

Net weight/GW |

780/820kg |

800/850kg |

1200/1250kg |

1600/1700kg |

|

|

Package dimensions |

Wooden case: 3150x1100x1860mm. (1x20GP loading quantity: 5 sets) |

||||

|

move |

Automatic (4 types) |

1. The pad frame is vertically up and down 180° automatically |

|||

|

2. Boom in/out 610/760mm automatic |

|||||

|

3. Automatic lifting and lowering of power arm |

|||||

|

4. Lateral side shift 100mm automatically |

|||||

|

Manual (2 types) |

5. Pedestal frame tilts 90° left/right Manual (please see optional 1. Automatic steering lift/right) |

||||

|

6. The pad frame rotates 360° manually (see option 2. Automatically rotates 360°) |

|||||

|

usage |

Specially designed to handle different types of thick plates, such as steel, glass, granite, marble, etc., and equipped with vacuum suction covers of different materials. |

||||

Click hereGet the latest offer...

1. Integrated control system ensures fast and automatic vertical and horizontal positioning.

2. DC24V reliable lifting, extending and tipping actuators, efficient and precise.

3. Efficient, save manpower, and can greatly improve the working environment.

4. The vacuum spreader has been shot blasted and painted to prevent corrosion.

5. The high-quality pump station makes the vacuum spreader rise and fall smoothly.

6. High quality hydraulic cylinder to ensure smooth operation.

-

Box-type vacuum tube lifting assists the manipulator in lifting and moving

-

400KG~1000KG mini electric vacuum panel lifter for marble stone metal moving

-

Air-conditioning external machine lifting sling hand-shaking lifting bracket lifting crane tool hand-shaking belt self-locking

-

Nemo Patented Design Grabo H V2 Electric Suction Cup Tool Grabo Electric Vacuum Suction Cup Lifter for Glass Tile Wood Wall Stone

-

Factory 200~600kg mini manual vacuum glass suction lifter

-

2022 New Products Portable Electric Suction Cup Heavy Duty Wooden Vacuum Cleaner Grabo Pro Suction Cup

-

800kg 5m lifting height battery stone flipper marble slab granite trolley vacuum wheel lifter glass robot

-

Portable Electric Vacuum Lifter Max. Load 375lbs for lifting wood marble granite glass brick concrete

-

2020 hot selling manual vacuum glass regulator

-

China DAXLIFTER Brand 300-800kg 3.5m Granite Glass Vacuum Lifter

Other Products

-

$4090.00 - $4306.00 / set

$4090.00 - $4306.00 / set -

$1000.00 / set

$1000.00 / set -

$6000.00 / set

$6000.00 / set