Glass essential oil distiller distillery manufacturer trade CE

-

Supplier: Guangzhou Aolantec Commerce And Trade Co., Ltd. -

Region: Beijing, China -

Contact: Ms Tiffany Shang -

Price: $100.00 /set -

Min. Order: 1 set

Product details

| Core components: | engine, motor | Dimensions (L*W*H): | 67*35*50 |

| Main selling points: | automatic | place of origin; place of origin: | China |

| Packaging Details: | Carton or according to your needs | Material: | 304 stainless steel |

| Voltage: | 220V | Supply capacity: | 50000 sets per month |

| color: | custom made | Mechanical test report: | if |

| Warranty: | 1 year | brand: | Orantec |

| Video shipment inspection: | if | capacity: | 10L/21L/32L/55L |

| Energy source: | electrical | Health status: | new |

| process: | hot | strength: | 2500 |

| Marketing Type: | normal product | Raw materials: | Flowers herbs roots plants leaves etc. |

| Core component warranty: | 1 year | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Applicable industries: | Manufacturing, Home, Other, Hotel, Manufacturing, Food & Beverage, Farm, Restaurant, Home, Retail, Food Store, Food & Beverage | After warranty service: | Video technical support, online support, spare parts |

| Showroom location: | not any | product name: | essential oil distiller |

| Certification: | CE/ISO9001 | weight: | 12 kg |

| port: | Shanghai Guangzhou Qingdao |

List of functions

Product overview

1. The essential oil hydrosol extraction machine can choose different capacities from 10-55 liters to extract fruits and vegetables, Chinese style

Herbs, flowers, dried flowers, trees and other essential oils, pure dew, distilled water, can also be brewed, one key

Operation.

2. This machine adopts the existing technology to remove heavy metals and pesticide residues in a planned way, with good quality.

3. One pot for 50 minutes, you can run for a whole day, 1-80 catties of pure dew/day/set of essential oils depends on the amount

plant.

4. It is suitable for home, beauty salon, SPA, flower garden, laboratory, botanical garden, wine making, beauty treatment, etc.

5. Capacity: 10L, 21L, 32L, 55L

Height: 66-88cm

Herbs, flowers, dried flowers, trees and other essential oils, pure dew, distilled water, can also be brewed, one key

Operation.

2. This machine adopts the existing technology to remove heavy metals and pesticide residues in a planned way, with good quality.

3. One pot for 50 minutes, you can run for a whole day, 1-80 catties of pure dew/day/set of essential oils depends on the amount

plant.

4. It is suitable for home, beauty salon, SPA, flower garden, laboratory, botanical garden, wine making, beauty treatment, etc.

5. Capacity: 10L, 21L, 32L, 55L

Height: 66-88cm

product configuration

working principle

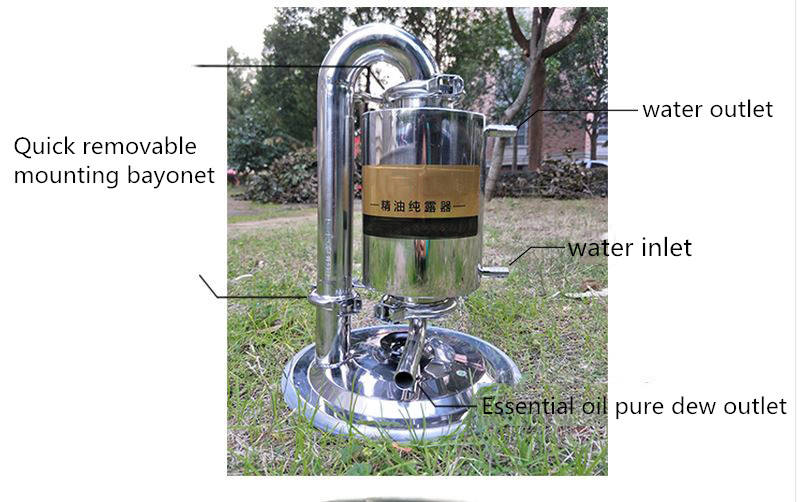

1. Steam distillation:

It is the most widely used today. But the steps are relatively complicated, because the mixed water in the extracted essential oil needs to be removed first.

2. Solvent extraction method:

2. Solvent extraction method:

The extraction time is long and the efficiency is low.

3. Expression method:

3. Expression method:

High-quality essential oils can be obtained by crushing, pressing, and separating raw materials.

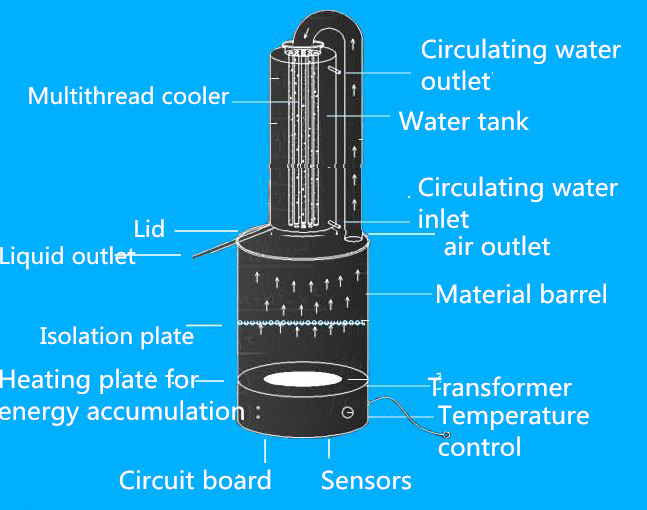

detailed drawing

product specification

Model | Voltage /V | Maximum power/W | Packing size/cm | weight/kg | Tank diameter/cm | Overall height/cm | Material filling amount/kg | Pure dew volume/kg |

10L | 220-240 | 2500 | 67*35*50 | 12 | 25 | 70 | 1.5 | 2.5 |

21L | 220-240 | 2500 | 67*35*50 | 13 | 30 | 80 | 2.5 | 6 |

32L | 220-240 | 3000 | 85*45*55 | 18 | 35 | 85 | 5 | 12.5 |

55L | 220-240 | 3000 | 90*50*65 | twenty two | 40 | 105 | 10 | 25 |

advantage:

1. Central poly ring, fast heating, energy saving

Gather energy and heat to accelerate the extraction of essential oils

10 minutes to quickly make essential oils, 50 minutes to complete, continuous work

2. Waste discharge does not burn

Lack of water will not burn the pot

Drying automatic power off

3. Adopt multi-thread cooling device to make cooling more efficient

Multi-threaded cooling pipe, zero loss, cooling efficiency is 10 times that of traditional coolers

4. Easy to clean, no smell

Gather energy and heat to accelerate the extraction of essential oils

10 minutes to quickly make essential oils, 50 minutes to complete, continuous work

2. Waste discharge does not burn

Lack of water will not burn the pot

Drying automatic power off

3. Adopt multi-thread cooling device to make cooling more efficient

Multi-threaded cooling pipe, zero loss, cooling efficiency is 10 times that of traditional coolers

4. Easy to clean, no smell

VIEW MORE

You may like

-

Collagen making machine

-

Lab1st Rotovap 5l Rotary Vacuum Evaporator Price

-

Best Selling Smart Watch D20 y68 Big Screen Smart Watch I7pro Max Smart Watch Iwo Series 7 Smart Watch I7 Pro Max

-

Laboratory essential oil extraction water distiller purifier distillation device

-

Fully automatic essential oil distiller distillation equipment machine water pure dew perfume aroma DIY tea tree stainless steel

-

Automatic Essential Oil Vacuum Steam Distillation Extraction Machine Equipment Tank Instrument Kit Plant Herb 50L 100 5000 Liters

-

Small pure steam generators for the pharmaceutical and healthcare industries

-

ZZKD glass laboratory equipment vacuum distillation system kit 2l 5l 10l 20l short path distillation

-

Small Essential Oil Extractor Extraction Distiller Distillation Distillation Equipment Machine Instrument Kit Kit Unit Set Equipment

-

China Famous Brand Low Price MVR Evaporator

Other Products

-

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set -

$200.00 / set

$200.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set

Related Search

make essential oil distiller suppliers

essential oil distillation equipment

steam distillation essential oil extraction

distillation of essential oil suppliers

essential oil machinery

essential oil bag

essential oil case doterra

oils distillation machine used

fuel oil distillation

small oil distiller machine