Times electric factory direct sales of locomotives Narrow gauge electric locomotives for tunnels Sales of supporting vehicles Locomotive prices

-

Supplier: Gansu Times Power Technology Development Co., Ltd. -

Region: Gansu, China -

Contact: Ms Juliana Wei -

Price: $238095.24 / 1 - 3 sets

$222222.22 / >=4 sets -

Min. Order: 1 set

Product details

| port: | Tianjin Qingdao | Speed (km/h): | 8.8 km/h |

| Dimensions (LxWxH) (mm): | 8260*1550*2400mm | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, Trade Assurance |

| place of origin; place of origin: | Gansu, China | Start towing: | 143KN |

| Keep pulling forward: | 110KN | Supply capacity: | Monthly production of 30 65-ton lithium battery mining locomotives |

| Gasoline type: | electrical | brand: | power of the times |

| Package preview: | horsepower: | 435.07 | |

| transfer method: | DC-AC | Wheel Diameter: | 840mm |

| strength: | 135KW*2 | Air compressor: | 0.5-0.8Mpa |

| Packaging Details: | wooden box | battery voltage: | DC540V |

| Maximum speed: | 15km/h | product name: | underground mining locomotive |

| Measurement: | 900mm/762mm |

product description

XK, LK, and SC electric locomotives are narrow-gauge mining electric locomotives driven by DC, which can supply power

Consists of batteries, lithium batteries and supercapacitors. It is mainly used in non-explosion-proof places such as coal mines, metallurgical mines, forests, subway tunnels, railway tunnels, kilometers and other traffic traction, and narrow-gauge railway grounds.

Tunnel construction and other industries.

Consists of batteries, lithium batteries and supercapacitors. It is mainly used in non-explosion-proof places such as coal mines, metallurgical mines, forests, subway tunnels, railway tunnels, kilometers and other traffic traction, and narrow-gauge railway grounds.

Tunnel construction and other industries.

Power of the Times Supporting sales of domestic tunnel narrow-gauge electric locomotives | ||||||||

model | XK (LK/SC) 55 | |||||||

aspect | 8260×1550×2400mm | |||||||

Measurement | 900mm/762mm | |||||||

strength | 135KW×2 | |||||||

start towing | 143KN | |||||||

Keep pulling forward | 110KN | |||||||

continuous speed | 8.8 km/h | |||||||

Maximum speed | 15km/h | |||||||

Minimum Negotiable Curve Radius | 30 meters | |||||||

wheel diameter | 840mm | |||||||

launch method | DC-AC | |||||||

control method | intelligent microprocessor | |||||||

weight | 55000Kg | |||||||

Comment:This price is the price of the locomotive. If you want to know the supporting vehicle information, please contact us! !

Product Details

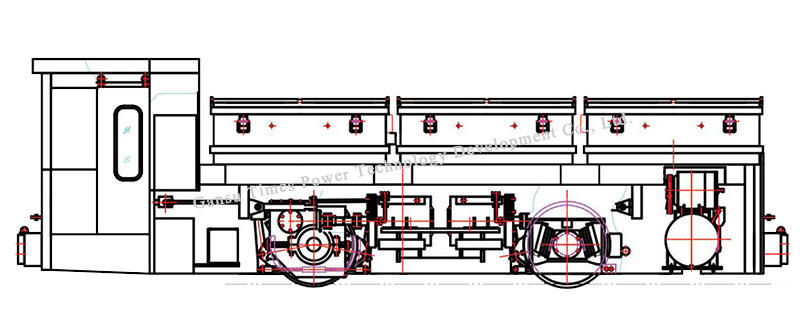

General layout of the locomotive

The locomotive is mainly composed of the cab traction variable resistance cabinet, electric control cabinet, frame, running system, traction motor, air brake system, control system, monitoring system, etc.

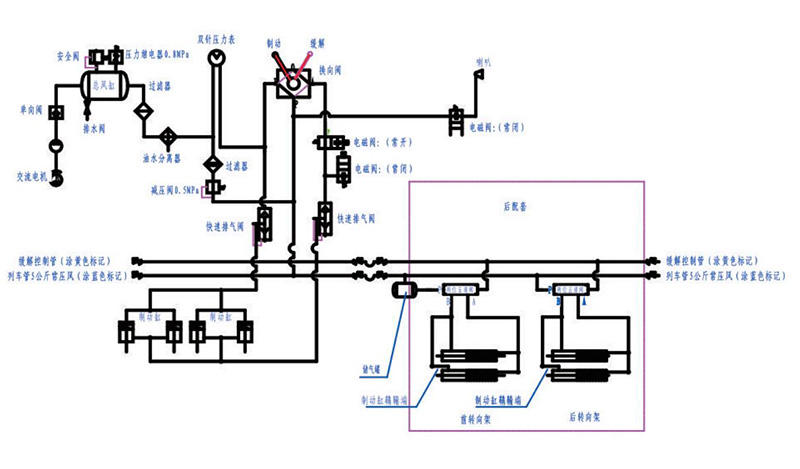

Locomotive air brake system

★Double-acting cylinder brake system, with airless parking function, ensures the safety of long-term parking. ★The conventional braking of the locomotive has feedback braking and resistance braking.

★When the control system breaks down, the braking system will start automatically, which can effectively prevent skid accidents caused by control system failure and human factors during driving.

★Emergency brake: anti-slip hook device.

★When the control system breaks down, the braking system will start automatically, which can effectively prevent skid accidents caused by control system failure and human factors during driving.

★Emergency brake: anti-slip hook device.

Mechanical Transmission and Shock Absorbers

The mechanical transmission system of the locomotive is composed of the travel gearbox (as shown in the figure), the universal coupling and the locomotive travel part; due to the poor line conditions of the mine locomotive, in order to reduce the vibration of the locomotive, reduce the impact between the wheel and rail of the locomotive, and improve the locomotive Stability and reliability, reduce the amount of maintenance, using a herringbone rubber elastic traction shock absorber (as shown).

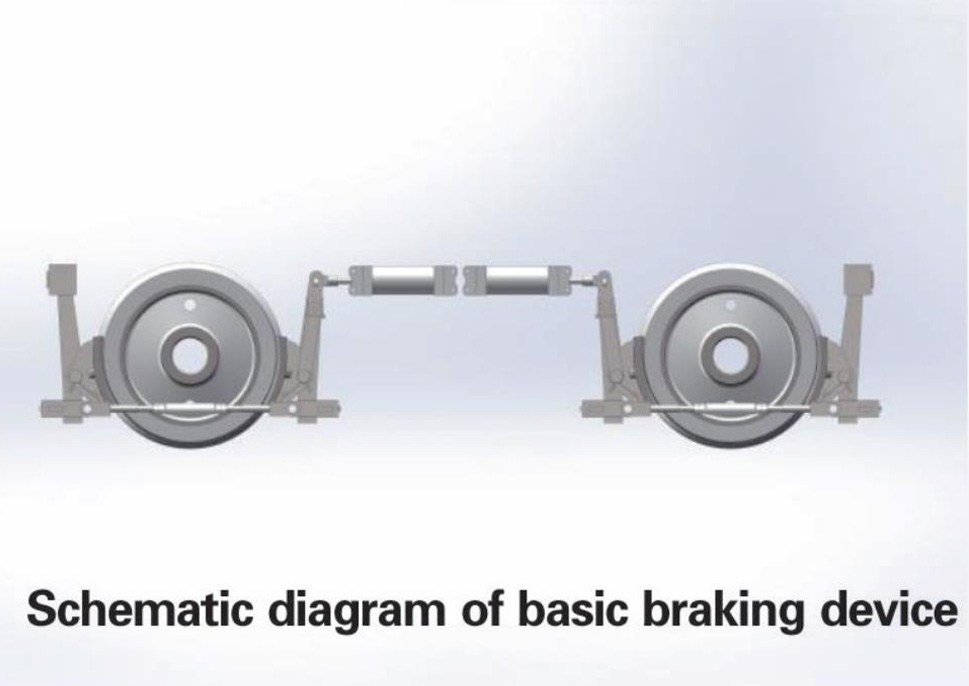

Basic braking device of locomotive

The basic braking device is composed of a double-acting brake cylinder, a linkage mechanism brake shoe seat and a brake shoe, and a brake shoe clearance adjustment mechanism. Each wheel has a brake. When braking, the compressed air pushes the Gobe and uses the lever mechanism to brake the brake shoe support roller.

product display

Product Configuration Description

1. The frequency converter uses a 32-bit digital signal DSP as the control unit, which integrates frequency control, slip control, and vector control, and can realize dynamic control. It has the advantages of good output waveform, large suction torque, and high strength. Self-adjustment and quick response. Through the S-type governor and flexible PWM energy consumption braking, the locomotive can run smoothly on the long slope.

2. The display adopts a large screen. Display real-time vehicle speed, operating frequency, battery voltage, quantity and fault information for easy operation and maintenance.

2. The display adopts a large screen. Display real-time vehicle speed, operating frequency, battery voltage, quantity and fault information for easy operation and maintenance.

3. If the inverter fails (such as lu2, pc, sc, fan failure), the emergency air brake will start automatically. Avoid sliding accidents (especially on heavily loaded ramps).

4. The single-acting brake cylinder is changed to double-acting brake cylinder, which improves the braking reliability.

5. There is a micro-movement device to adjust the loading and unloading position.

6. The traction motor adopts AC variable frequency traction motor, which has a wide speed range (0HZ-90HZ), strong load capacity and high insulation level.

4. The single-acting brake cylinder is changed to double-acting brake cylinder, which improves the braking reliability.

5. There is a micro-movement device to adjust the loading and unloading position.

6. The traction motor adopts AC variable frequency traction motor, which has a wide speed range (0HZ-90HZ), strong load capacity and high insulation level.

VIEW MORE

You may like

-

2.5 ton mining battery locomotive for undergroud tunnel

-

CJY10 tons mining trolley locomotive

-

CRRC produces passenger cars and freight cars for railway locomotives

-

Underground 12 Ton Battery Accumulator Locomotive for Mining

-

7-Ton Trolley Accumulator Locomotive for Mining

-

TimesPower Made in China Narrow Gauge Tram Mining Electric Locomotive Tunnel Locomotive

-

Explosion-proof 8-Ton Battery Accumulator Locomotive for Coal Mine

-

Custom Diesel Locomotives For Sale

-

2.5T lithium battery railway narrow gauge mine electric locomotive

-

3-Ton Narrow Gauge Trolley Locomotive for Mining

Other Products

-

$88000.00 - $90000.00 / set

$88000.00 - $90000.00 / set -

$288.00 / set

$288.00 / set

Related Search

oil pressure sensor factory direct sale

factory direct computer hardware

loop factory direct bow

factori direct chainsaw suppliers

factory direct epson printers

factori mattress sale suppliers

electric motor for sale

direct sales networking

direct sales sand washing machine

electric transformers for sale suppliers