LBTZ-II Top Manufacturer Medical Absorbent Cotton Bleaching Machine

-

Supplier: Qingdao Lebon Industry Co., Ltd. -

Region: Shandong, China -

Contact: Ms Sophia Ding -

Price: $5000.00 / 1 - 1 sets

$4800.00 / >=2 sets -

Min. Order: 1 set

| Automatic level: | automatic | Packaging Details: | export standard |

| Dimensions (L*W*H): | 1670X1990X2450MM | Video shipment inspection: | if |

| Showroom location: | Philippines, Mexico | Warranty: | 1 year |

| weight: | 10 tons | Mechanical test report: | if |

| Certification: | ISO9001 | payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Cash |

| place of origin; place of origin: | Shandong China | Health status: | new |

| After-sales service provided: | Engineers can provide overseas service machinery, on-site installation, commissioning and training, on-site maintenance and repair services | Supply capacity: | 10 sets per month |

| Final product: | raw cotton | application: | cotton products |

| Voltage: | 380V | Core component warranty: | 5 years |

| Material: | raw cotton | Core components: | PLC, engine, gearbox, motor |

| strength: | 2.2KW-6KW | Applicable industries: | manufacturing plant |

| width: | 1.5m-8m | port: | Qingdao |

| Local service location: | Saudi Arabia, Argentina | brand: | Le Bon |

| color: | custom made | capacity: | 150-500kg per hour |

| Production capacity: | 99% | Package preview: | |

| After warranty service: | Video technical support, spare parts, on-site maintenance and repair services | Marketing Type: | normal product |

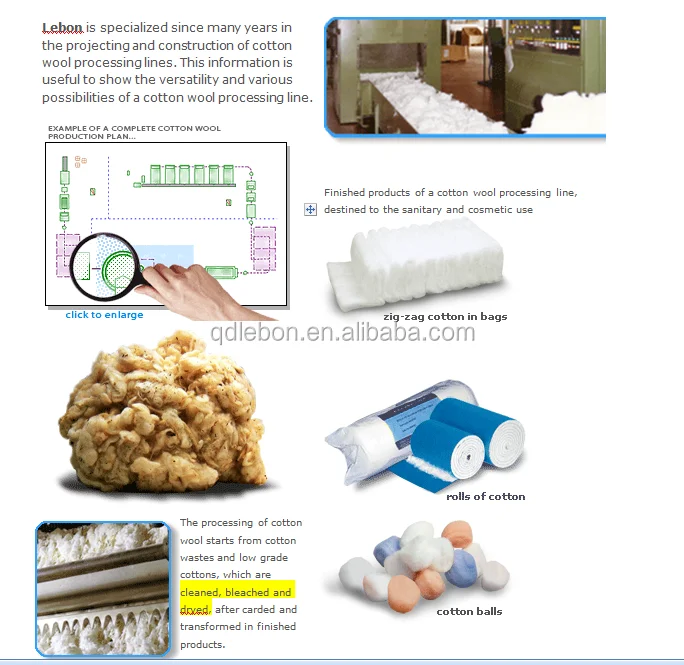

Process steps:

Medical Cotton Roll Surgical Cotton Machine

Specification

1. Surgical cotton roll machine can make 1.0g-6g

2.1.0-2g can produce 3-4 rolls at a time

3. Lap machine capacity 40-60kg/ 1 hour

The main technical parameters:

|

Width of medical cotton machine |

1020mm |

|

delivery speed |

20-220 m/min |

|

output |

25-80kg/hour |

|

Sliver weight |

3.6-6.5 g/m |

|

Continuous vacuum air volume |

3500 cubic meters per hour, Air pressure -850~950pa |

|

compressed air |

0.4-0.7Mpa |

|

Air consumption |

0.01M3/h, if the machine is equipped with closed-loop autoleveler, the air consumption is 0.03m3/h |

|

construction area |

3132*1974mm(L*w)(without coiler) |

|

total power |

6.88kw |

|

Surgical cotton machine net weight |

5500 kg |

Spare parts highlights:

1. One year warranty, forever technical and spare parts support.

2. When customers come to our factory for inspection, our factory will provide pre-test.

3. We provide detailed technical specifications, electrical diagrams, installation books, operation manuals, drawings, etc.

4. If the customer needs, we can send engineers to the customer's factory to help install and train workers.

-

Surgical cotton roll making machine

-

New Hand Cosmetic Cotton Pad Machine

-

Cast Iron Bleaching Machine Spare Parts

-

Surgical high capacity absorbent cotton bleaching machine

-

Hthp Vertical Fiber Yarn Dyeing Machine

-

H.T.H.P Fully Automatic Cone Yarn Dyeing Machines

-

Cone Yarn Dyeing Machine

-

Hthp Vertical Tubular Cone Dyeing Machine

-

HTHP Vertical Absorbent Cotton Bleaching Machine

-

HTHP Vertical Yarn Dyeing Machine

Other Products

-

$149000.00 - $150000.00 / set

$149000.00 - $150000.00 / set -

$4980.00 - $5000.00 / set

$4980.00 - $5000.00 / set -

$18800.00 - $19000.00 / set

$18800.00 - $19000.00 / set -

$50000.00 / set

$50000.00 / set -

High Capacity Fully Automatic Textile Ring Spinning Machine Production Line For Spinning Cotton Yarn$50000.00 / set

High Capacity Fully Automatic Textile Ring Spinning Machine Production Line For Spinning Cotton Yarn$50000.00 / set -

$5000.00 / set

$5000.00 / set -

$15000.00 / set

$15000.00 / set -

$64000.00 / set

$64000.00 / set -

$18000.00 / set

$18000.00 / set -

$30000.00 / set

$30000.00 / set