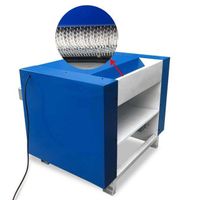

Professional Textile Cotton Cards for Open-End Yarns

-

Supplier: Qingdao Lebon Industry Co., Ltd. -

Region: Shandong, China -

Contact: Ms Sophia Ding -

Price: $19000.00 / 1 - 1 sets

$18800.00 / >=2 sets -

Min. Order: 1 set

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Production capacity: | 99% |

| Packaging Details: | export standard | Final product: | Cotton ball |

| feature: | High Yield Cotton Card | Voltage: | 380v-440v |

| port: | Qingdao | width: | 1m-2m |

| Material: | raw cotton | Key words: | carding machine |

| color: | custom made | brand: | Le Bon |

| Warranty: | 1 year | weight: | 5500 kg |

| Applicable industries: | manufacturing plant | application: | Open-end spinning, ring spinning, cotton carded yarn |

| strength: | 4~5.5kw | Function: | yarn making |

| Working width: | 1000-1500mm | Automatic level: | automatic |

| Core components: | PLC, motor | Core component warranty: | 1 year |

| After-sales service provided: | Engineers available to service machinery overseas | Supply capacity: | 50 sets per month |

| Dimensions (L*W*H): | 3300mm*1800mm*1800mm | Video shipment inspection: | if |

| Health status: | new | capacity: | 150-500kg per hour |

| Package preview: | Marketing Type: | normal product | |

| Mechanical test report: | if | Showroom location: | Indonesia, Pakistan |

| Origin: | Shandong China |

Spinning yarn professional textile cotton carding machine

Technical data:

The carding machine is suitable for processing cotton, cotton-type chemical fiber, and medium-length synthetic fiber raw materials.

The carding machine is a patented product successfully developed by our company's scientific research personnel. It is the most advanced fiber carding machine in China. The biggest advantage is that it uses a large roller and multiple small rollers to card three-dimensional cotton at a low speed (1400whirl/min), and the carding rate reaches 98. % above, the cotton will not be damaged during processing. Especially if there is a metal flaw detection alarm, it will be shut down immediately and there will be water leakage. The carding machine has the advantages of small size, good quality, long life and low maintenance rate.

And it can automatically unload the cotton to ensure the safety of the operator

Our Carding and Spinning Machine Workshop:

Carding machine main technical parameters:

|

width |

1020 mm |

|

delivery speed |

20-220 m/min |

|

output |

25-80kg/hour |

|

Sliver Weight |

3.6-6.5 g/m |

|

Continuous vacuum air volume |

3500 cubic meters per hour, Air pressure -850~950pa |

|

compressed air |

0.4-0.7Mpa |

|

Air consumption |

0.01M3/h, if the machine is equipped with closed-loop autoleveler, the air consumption is 0.03m3/h |

|

construction area |

3132*1974mm(L*w)(without coiler) |

|

total power |

6.88kw |

|

Net weight of carding machine |

5500 kg |

Highlights of our spare parts for cotton card and spinning machines:

1. One year warranty, forever technical and spare parts support.

2. When the customer comes to the factory for inspection, our factory will provide a pre-test.

3. We provide detailed technical specifications, electrical diagrams, installation books, operation manuals, drawings, etc.

4. If the customer needs, we can send engineers to the customer's factory to help install and train workers.

-

High quality electric wool polyester/needleloom machine

-

B272A Wool worsted wool fiber carding machine

-

Tunisian Sheep Wool Yarn Cotton Fiber Fabric Textile Fully Automatic Mini Small Carding Machine

-

Combing machine with electric comb with small wool thread for sale

-

Bed quilt cotton fiber ball cotton rolling machine cotton fiber opening and carding machine quilt manufacturing machine

-

Combing machine with mini cotton thread for combing opening

-

Small alpaca carding machine for sale

-

Cotton Wool Rolling Machine Cotton Fiber Carding Machine Used Cotton Uncoiler For Clothes Recycling

-

Mini Worsted Yarn Fiber Wool Net Sliver Combing Machine Fabric Knitting Manufacturing Machine Textile Cotton Sheep Wool Carding Combing Machine

-

Carding sliver hand wool carding and spinning machine price machine wool carding machine

Other Products

-

$149000.00 - $150000.00 / set

$149000.00 - $150000.00 / set -

$4980.00 - $5000.00 / set

$4980.00 - $5000.00 / set -

$4800.00 - $5000.00 / set

$4800.00 - $5000.00 / set -

$50000.00 / set

$50000.00 / set -

High Capacity Fully Automatic Textile Ring Spinning Machine Production Line For Spinning Cotton Yarn$50000.00 / set

High Capacity Fully Automatic Textile Ring Spinning Machine Production Line For Spinning Cotton Yarn$50000.00 / set -

$5000.00 / set

$5000.00 / set -

$15000.00 / set

$15000.00 / set -

$64000.00 / set

$64000.00 / set -

$18000.00 / set

$18000.00 / set -

$30000.00 / set

$30000.00 / set